The Evolution and Impact of Rubber Tape Manufacturing

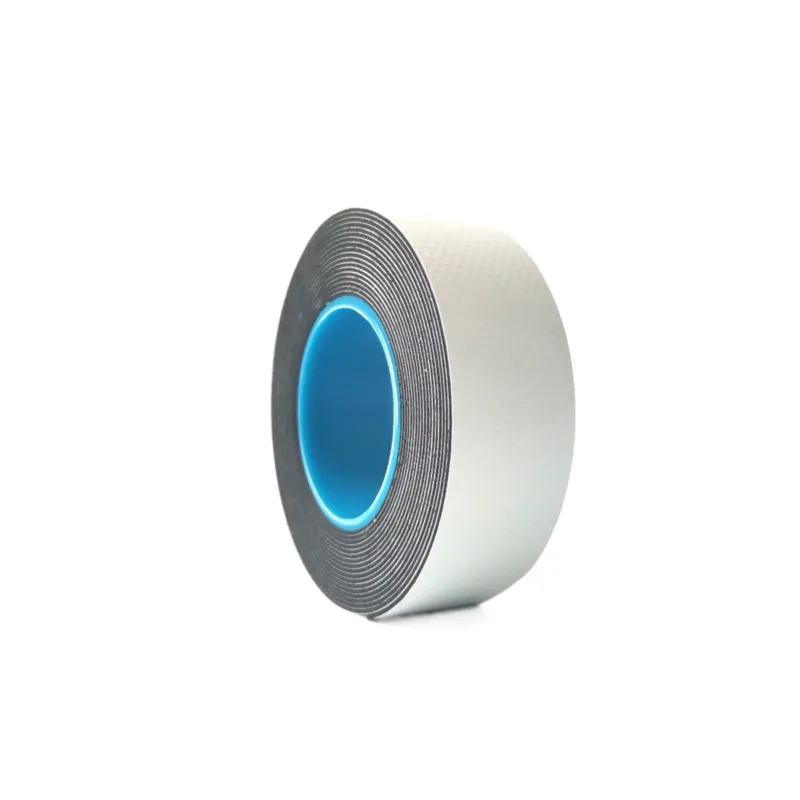

In the realm of manufacturing, few products exhibit the versatility and utility of rubber tape. Known for its excellent adhesion, durability, and resistance to moisture and chemicals, rubber tape serves a multitude of purposes across various industries. The rubber tape factory has thus evolved into a critical part of the supply chain, providing essential products for construction, electrical applications, and everyday consumer use.

Historical Background

The usage of rubber in manufacturing can be traced back to ancient civilizations, but it wasn't until the 19th century that the industrial production of rubber products began to flourish. With the invention of vulcanization by Charles Goodyear in 1839, rubber's properties were significantly enhanced, opening the doors for diverse applications, including the production of tapes. Rubber tape soon became popular due to its ability to withstand harsh environmental conditions while providing strong adhesive qualities.

Manufacturing Process

The production of rubber tape involves several steps. Initially, raw materials are procured. These often include natural and synthetic rubber, adhesives, and various additives to enhance performance characteristics. The manufacturing process typically begins with the mixing of rubber compounds. These compounds are then processed through calendaring or extrusion, forming a thin, flexible sheet.

Once the rubber sheet is prepared, a special adhesive layer is applied. This adhesive is critical for ensuring that the tape can bond effectively to a variety of surfaces. The coated rubber is then cut into specific widths and lengths according to product specifications. Quality control is paramount at each step to ensure the final product meets industry standards for performance and safety.

Applications of Rubber Tape

Rubber tape finds applications in numerous sectors. In the electrical industry, it is often used for insulation and protection of wires and connections, helping to prevent short circuits and electrical fires. Its water-resistant properties make it ideal for outdoor applications, where exposure to moisture and temperature variations is common.

In construction, rubber tape is utilized for sealing joints, preventing leaks, and providing a cushion or gasket in assemblies. It is especially useful in plumbing, HVAC, and automotive applications, where it can help to maintain system integrity and performance.

rubber tape factory

Moreover, the consumer market has embraced rubber tape for more mundane tasks. Whether for crafting, repairs, or DIY projects, consumers appreciate the convenience and efficacy of rubber tape. Its ease of use and reliable performance make it a staple in homes and workplaces alike.

Market Trends and Innovation

As industries evolve, so do the demands placed on rubber tape products. The rubber tape factory must adapt to these trends by innovating and improving formulations. For instance, the growing emphasis on sustainability has led manufacturers to explore eco-friendly rubber materials and adhesives. This shift not only meets consumer demand for greener products but also reduces the environmental impact of production.

Moreover, advancements in technology have streamlined the manufacturing process. Automation and precision engineering have significantly increased production efficiency, allowing factories to meet the demands of a global market. New testing technologies ensure that products exceed safety regulations, offering customers peace of mind.

The Global Landscape

Rubber tape manufacturing has a global footprint, with major production hubs in countries like China, the United States, and Germany. The interconnectedness of the global economy means that supply chains are often complex, involving multiple nations for sourcing raw materials and distributing finished products.

As globalization continues to shape the marketplace, rubber tape factories must navigate challenges such as fluctuating raw material prices and trade regulations. Staying competitive requires not only maintaining quality and cost-effectiveness but also being responsive to the changing preferences of a diverse customer base.

Conclusion

The rubber tape factory stands as a testament to the advancements in material science and manufacturing technology. By providing essential products that serve a wide range of applications, these factories play a pivotal role in modern industry and everyday life. As we look to the future, innovation and sustainability will be at the forefront, ensuring that rubber tape remains a valuable resource for generations to come.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025