Understanding Rubber Tape Insulation A Comprehensive Guide

Rubber tape insulation is an important material widely used in various applications, particularly in electrical work and insulation. It is a versatile, flexible tape that provides reliable electrical insulation while offering excellent mechanical protection. This article aims to explore the features, benefits, and applications of rubber tape insulation, highlighting its significance in both commercial and residential settings.

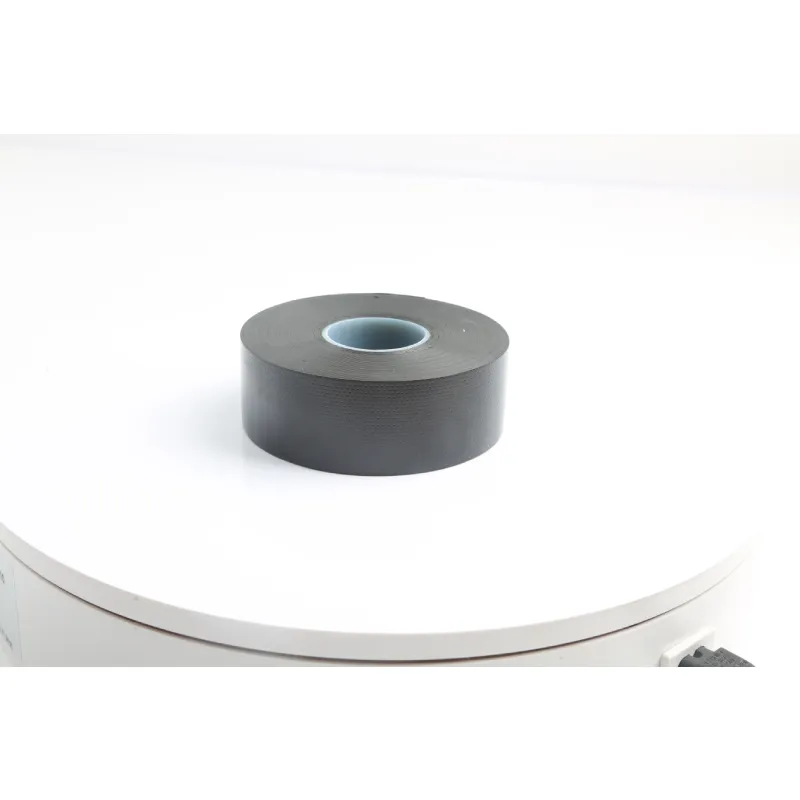

What is Rubber Tape Insulation?

Rubber tape insulation is a self-fusing, non-vulcanizing tape made primarily from rubber, which gives it the ability to wrap tightly around itself without the need for adhesive. This type of tape is often used in applications where electrical insulation is crucial due to its ability to withstand moisture, chemicals, and temperature fluctuations. It is available in various sizes and thicknesses, catering to different needs.

Key Features

1. Self-Fusing Properties One of the standout features of rubber tape insulation is its self-fusing capability. When wrapped around a surface, the tape bonds to itself, creating a tight seal that prevents moisture ingress and protects against environmental elements.

2. Electrical Insulation Rubber tape provides excellent electrical insulation properties, making it ideal for electrical repairs, splices, and terminations. It helps to prevent short circuits and electrical failures, ensuring safety in various applications.

3. Temperature Resistance This type of insulation can withstand varying temperatures, making it suitable for both indoor and outdoor use. It is designed to remain flexible and functional in extreme conditions, thus ensuring durability and reliability.

4. Chemical Resistance Rubber tape is resistant to various chemicals and oils, making it an excellent choice for industrial applications where exposure to such substances is common.

Benefits of Using Rubber Tape Insulation

- Versatility The versatility of rubber tape insulation allows it to be used in a wide range of applications—from electrical maintenance to plumbing repairs. Its ability to conform to different shapes and surfaces makes it an indispensable tool in many trades.

rubber tape insulation

- Ease of Use Rubber tape is easy to apply, even for individuals who may not have extensive experience in electrical work

. It does not require additional tools for application, making it a convenient choice for quick repairs.- Enhanced Safety By providing reliable insulation for electrical wires and components, rubber tape reduces the risk of electrical hazards. Proper insulation helps to prevent electrical shocks and fires, promoting safer working environments.

Applications

Rubber tape insulation finds utility in numerous domains

- Electrical Maintenance It is commonly used to insulate exposed wires, repair cable jackets, and create moisture barriers around electrical connections.

- Automotive Industry In vehicles, rubber tape is utilized for protecting wires and cables from abrasion, moisture, and chemical exposure, ensuring the longevity and reliability of electrical systems.

- Home Repairs Homeowners often turn to rubber tape for quick fixes around the house, such as sealing pipes or repairing damaged cords, due to its easy application and effective results.

- Industrial Use In industrial settings, rubber tape is employed to insulate machinery and ensure that equipment continues to operate safely and efficiently in various conditions.

Conclusion

In summary, rubber tape insulation serves as a crucial component in a wide variety of applications, providing electrical insulation, mechanical protection, and resistance to environmental factors. Its self-fusing properties, combined with its versatility and ease of use, make it a favored choice among professionals and DIY enthusiasts alike. Whether for electrical repairs, automotive applications, or general maintenance, rubber tape insulation proves to be an effective and reliable solution.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025