The Evolving Landscape of Rubber Tape Manufacturers

In today's fast-paced and innovative world, the demand for versatile and durable materials continues to rise. Among these materials, rubber tape has secured its position as a reliable solution for a variety of industries, from electrical and automotive to construction and manufacturing. The evolution of rubber tape manufacturers is a testament to their adaptability and commitment to quality, driving advancements in product development and customer satisfaction.

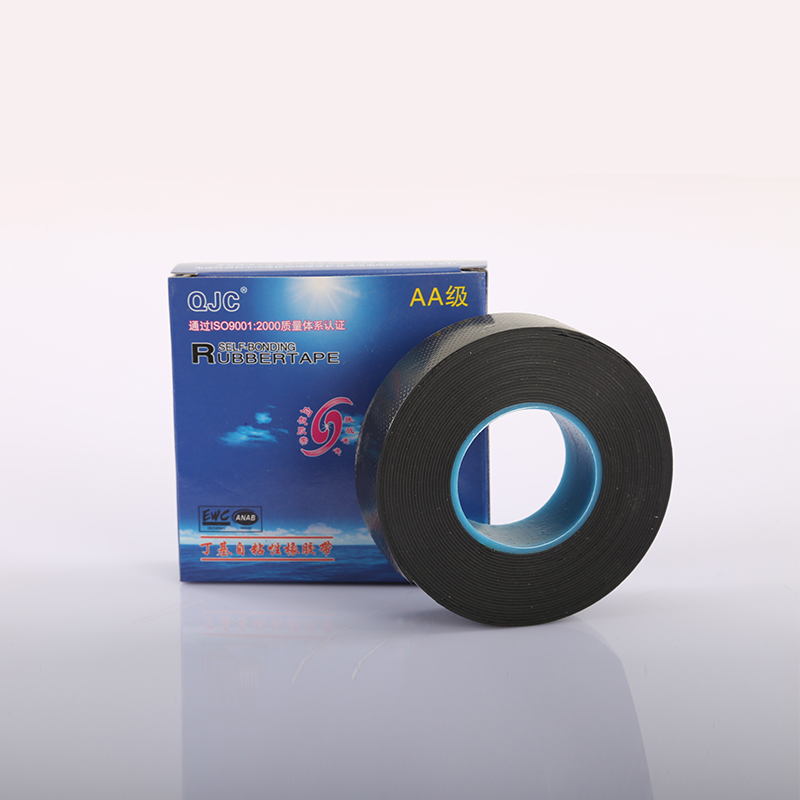

Rubber tape is known for its exceptional properties, including flexibility, durability, and resistance to various environmental conditions. These characteristics make it an ideal choice for a wide range of applications, including insulation, sealing, and repairs. As the needs of various sectors grow more complex, rubber tape manufacturers have expanded their product lines and improved the formulations of their tapes to meet these demands.

One of the primary industries benefiting from rubber tape is the electrical sector. Manufacturers have developed specialized types of rubber tape that provide superior insulation and protection against moisture, heat, and chemicals. For instance, self-fusing rubber tape is a popular choice among electricians, as it bonds to itself without the need for adhesives, creating a waterproof seal capable of withstanding high temperatures. This type of tape has become a staple in many electrical applications, from wiring repairs to insulation for connectors, showcasing the innovation within the rubber tape manufacturing industry.

Additionally, the automotive sector has embraced rubber tape for a variety of applications. With the rise of electric vehicles and evolving manufacturing processes, rubber tape is utilized in sealing joints, protecting sensitive components from moisture, and providing insulation. Manufacturers have responded to this demand by creating tapes that meet the rigorous standards required for automotive applications, including resistance to extreme temperatures and exposure to various chemicals. This focus on automotive-specific products illustrates the manufacturers' understanding of industry needs, driving them to develop tailored solutions that enhance vehicle performance and longevity.

rubber tape manufacturers

Moreover, the construction industry increasingly relies on rubber tape for a multitude of purposes, including waterproofing and surface protection. In the battle against moisture intrusion, manufacturers offer rubber tapes designed to create impermeable barriers on roofs and foundation walls. These tapes provide peace of mind to builders and homeowners alike, ensuring that structures remain safe and dry. As a result, the reputation of rubber tape as a reliable construction material has solidified, prompting manufacturers to continue innovating in this space.

With the global growth of e-commerce, rubber tape manufacturers have also expanded their reach, facilitating easier access to their products. Many manufacturers now offer online ordering systems, allowing businesses and consumers to quickly procure the specific types of rubber tape they need, regardless of location. This shift not only streamlines the purchasing process but also allows manufacturers to gather valuable customer feedback, which can inform future product development.

Sustainability has also become a driving force in the evolution of rubber tape manufacturers. As industries worldwide work towards reducing their environmental impact, many manufacturers are exploring eco-friendly materials and production practices. This movement has led to the development of biodegradable rubber tapes and initiatives aimed at reducing waste during the manufacturing process. Companies that adopt sustainable practices are not only meeting regulatory requirements but are also appealing to a growing demographic of environmentally conscious consumers.

In conclusion, the world of rubber tape manufacturers is dynamic and ever-changing, driven by technological advancements and a deep understanding of industry needs. From electrical insulation to automotive applications and construction solutions, rubber tape has established itself as a crucial material across diverse sectors. As manufacturers continue to innovate and adapt, the future promises even more exciting developments. By focusing on quality, customer satisfaction, and sustainability, rubber tape manufacturers are poised to maintain their pivotal role in shaping industries for years to come.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025