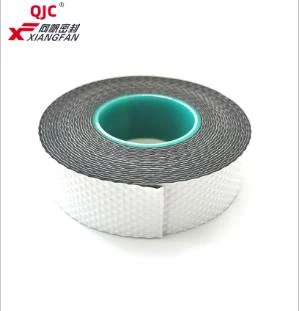

Rubber waterproof composite tape

Back to list

Jan . 09, 2025 10:35

Rubber tapes, a pivotal component in various industrial applications, are crafted by specialized manufacturers who focus on quality and innovation. The industry of rubber tape manufacturing is deeply rooted in rich expertise and stands as a testament to the dedication of professionals who have honed their craft over decades.

Trustworthiness is the cornerstone upon which these manufacturers build long-lasting relationships with their clients. By ensuring consistent product quality and exceptional customer service, they foster a dependable market presence. Feedback systems and after-sales assistance contribute to their reputation, providing clients with a sense of security and partnership. Trust is further solidified through transparent business dealings and environmentally friendly manufacturing processes, demonstrating a commitment to ethical business practices. Innovative manufacturers are not resting on past laurels; they continuously innovate to absorb emerging trends and meet the evolving demands of modern industries. Emphasis is placed on research and development to explore new materials and processes that enhance the performance and longevity of rubber tapes. By embracing technological advancements such as automation and machine learning, production processes are optimized to be faster, more efficient, and less prone to human error. The pinnacle of success for rubber tape manufacturers is in their ability to connect with a global clientele while incorporating feedback to drive improvements. Effective communication channels allow them to gather insights, adapt to market changes, and anticipate future needs. In this way, these manufacturers stay ahead in a competitive landscape, offering products that not only meet but often exceed client expectations. In conclusion, rubber tape manufacturers epitomize the integration of experience, expertise, authority, and trust. Their commitment to quality, customization, compliance, and client satisfaction ensures that they remain indispensable partners across various industries. By continuing to innovate and adapt, they sustain their status as leaders in the art and science of rubber tape manufacturing.

Trustworthiness is the cornerstone upon which these manufacturers build long-lasting relationships with their clients. By ensuring consistent product quality and exceptional customer service, they foster a dependable market presence. Feedback systems and after-sales assistance contribute to their reputation, providing clients with a sense of security and partnership. Trust is further solidified through transparent business dealings and environmentally friendly manufacturing processes, demonstrating a commitment to ethical business practices. Innovative manufacturers are not resting on past laurels; they continuously innovate to absorb emerging trends and meet the evolving demands of modern industries. Emphasis is placed on research and development to explore new materials and processes that enhance the performance and longevity of rubber tapes. By embracing technological advancements such as automation and machine learning, production processes are optimized to be faster, more efficient, and less prone to human error. The pinnacle of success for rubber tape manufacturers is in their ability to connect with a global clientele while incorporating feedback to drive improvements. Effective communication channels allow them to gather insights, adapt to market changes, and anticipate future needs. In this way, these manufacturers stay ahead in a competitive landscape, offering products that not only meet but often exceed client expectations. In conclusion, rubber tape manufacturers epitomize the integration of experience, expertise, authority, and trust. Their commitment to quality, customization, compliance, and client satisfaction ensures that they remain indispensable partners across various industries. By continuing to innovate and adapt, they sustain their status as leaders in the art and science of rubber tape manufacturing.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025