The Importance of Seal Strips in Modern Applications

Seal strips, often referred to as weatherstripping or sealing strips, are essential components used in a wide range of modern applications. These versatile materials serve a critical role in providing insulation, enhancing energy efficiency, and improving the overall functionality of various products, from windows and doors to vehicles and appliances.

At their core, seal strips are designed to fill the gaps between surfaces, preventing air, water, dust, and noise from entering or escaping. This functionality is particularly important in residential and commercial buildings, where proper sealing can lead to significant energy savings. By minimizing air leaks, seal strips help maintain stable indoor temperatures, reducing the reliance on heating and cooling systems. This not only lowers energy bills but also lessens the overall environmental impact by decreasing carbon emissions.

In the automotive industry, seal strips are critical as well. They are used extensively in vehicles to provide airtight seals around doors, trunk hoods, and windows, protecting passengers from external elements and ensuring a quiet ride. Quality seal strips help prevent wind noise and water intrusion, which can lead to mold and mildew if left unchecked. Additionally, they aid in reducing vibrations, contributing to a smoother driving experience.

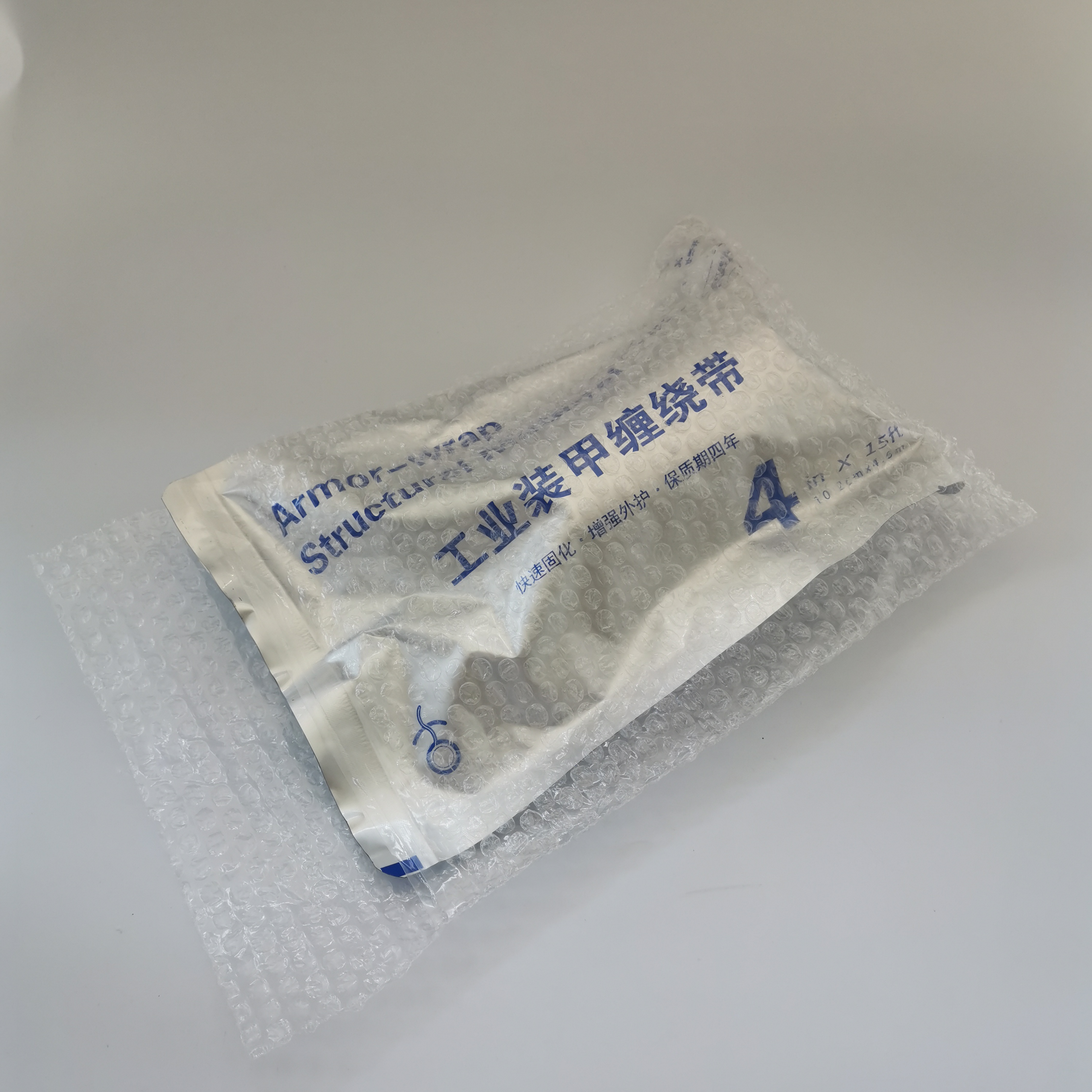

seal strip

The manufacturing of seal strips has evolved significantly over the years, with advancements in materials and technology

. Traditionally made from rubber or felt, modern seal strips often utilize innovative materials such as silicone, thermoplastic elastomers (TPE), and polyurethane foam. These materials not only offer better durability and flexibility but also enhance performance in extreme temperatures and harsher environmental conditions.Furthermore, the application of seal strips extends to appliances where they are used to create airtight seals on refrigerators, ovens, and washing machines. In refrigerators, for instance, effective sealing keeps cold air inside, ensuring optimal performance and preserving food freshness. In ovens, seal strips help maintain consistent cooking temperatures, thereby improving energy efficiency and cooking results.

Beyond practical uses, seal strips also contribute to aesthetics. Companies are now paying attention to how these components can seamlessly blend with various designs without compromising function. The development of sleek, low-profile seal strips has allowed manufacturers to enhance the visual appeal of their products while providing the necessary sealing functions.

In conclusion, seal strips are an integral part of numerous sectors, providing essential benefits that enhance energy efficiency, comfort, and aesthetics. As technology continues to advance, the materials and applications of seal strips are likely to evolve, leading to even more innovative solutions that address the challenges of today’s world. Whether in buildings, vehicles, or appliances, seal strips remain a vital aspect of modern design and functionality, playing a crucial role in ensuring a better quality of life.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025