The Versatility and Importance of Self-Amalgamating Electrical Tape

In the realm of electrical maintenance and repairs, few tools are as indispensable as self-amalgamating electrical tape. This specialized tape is engineered to offer superior insulation and protection for electrical connections, making it a staple for professionals and DIY enthusiasts alike. Its unique properties and ease of use make it an essential item in any toolbox.

What is Self-Amalgamating Electrical Tape?

Self-amalgamating electrical tape, also known as self-fusing tape, is a type of adhesive tape that does not have a sticky backing in the traditional sense. Instead, it functions by fusing to itself when stretched and wrapped tightly around an object. This self-bonding property allows the tape to create an airtight and water-resistant seal, making it extremely effective for a variety of electrical applications.

Key Features and Benefits

1. Insulation and Sealing One of the most significant advantages of self-amalgamating electrical tape is its excellent insulating properties. It can handle a wide range of temperatures, making it suitable for both indoor and outdoor applications. This tape provides a robust barrier against moisture, dust, and other contaminants, ensuring that electrical connections remain safe and functional.

2. Ease of Use Unlike traditional electrical tapes, which can be tricky to work with, self-amalgamating tape is remarkably user-friendly. It is easy to tear, and since it does not require a sticky surface, it can be applied effortlessly and repositioned if necessary. This feature is particularly useful in tight or awkward spaces where precision is crucial.

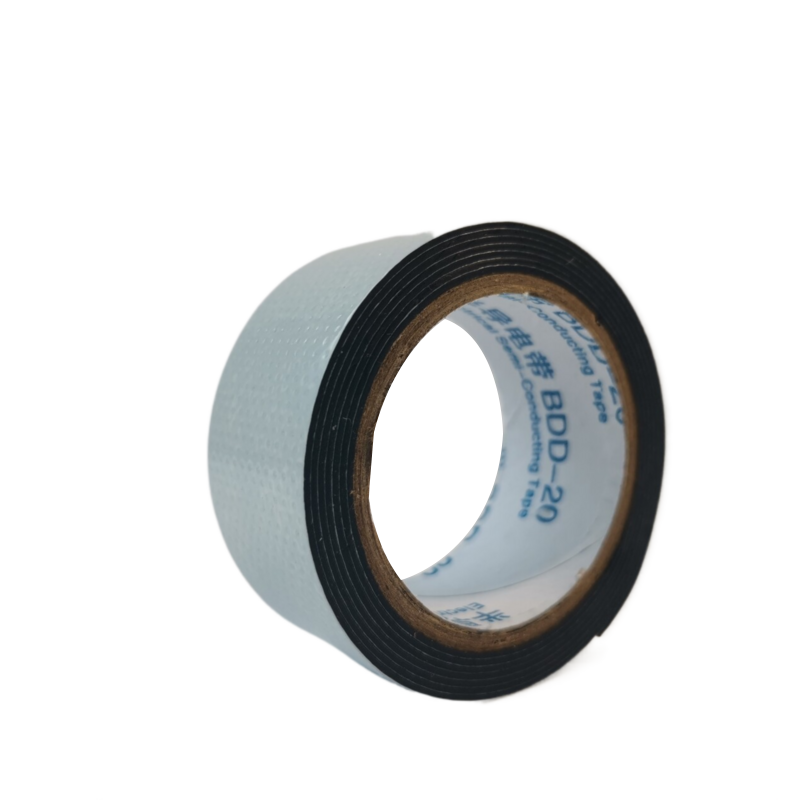

self amalgamating electrical tape

3. Durability This type of tape is designed to withstand harsh conditions, including extreme temperatures and exposure to UV light. As a result, it is an ideal choice for outdoor electrical applications, such as sealing connections on power lines or outdoor lighting fixtures. The durability of self-amalgamating tape ensures long-lasting protection and minimizes the need for frequent repairs.

4. Versatility Beyond electrical applications, self-amalgamating tape is also used in plumbing, automotive repairs, and even as a temporary fix for hoses and tubing. Its adaptability to various materials, such as rubber, plastic, and metal, expands its functionality considerably. Whether fixing a frayed wire or sealing a leaky pipe, self-amalgamating tape rises to the challenge.

Applications in Various Fields

In the electrical sector, this tape is commonly utilized for insulating high-voltage connections, bundling wires, and repairing damaged cords. Its robust nature minimizes the risk of electrical shorts, making it a favorite among electricians. In the automotive industry, mechanics use self-amalgamating tape to wrap and insulate the wiring harnesses and to protect electrical components from moisture damage.

Conclusion

Self-amalgamating electrical tape is a remarkable tool that plays a crucial role in ensuring safety and reliability in electrical applications. Its unique properties make it an invaluable asset across various fields, from construction to automotive repair. As technology advances and the need for durable, effective solutions grows, self-amalgamating electrical tape stands out as a versatile and efficient choice for both professionals and everyday users. Whether you’re tackling a complex electrical project or simply need a quick fix, incorporating self-amalgamating tape into your toolkit will undoubtedly enhance your repair capabilities. It is a small, yet powerful ally for anyone working with electrical systems.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025