The Versatility and Benefits of Self-Amalgamating Electrical Tape

Self-amalgamating electrical tape, also known simply as self-fusing tape, is a remarkable innovation in the realm of insulation and protection for a variety of electrical applications. With its unique properties and diverse uses, this type of tape has gained traction not only in professional electrical engineering but also among DIY enthusiasts and hobbyists. This article explores the characteristics, benefits, and applications of self-amalgamating electrical tape.

Understanding Self-Amalgamating Tape

Self-amalgamating tape is primarily made from a silicone or rubber compound that allows it to bond to itself upon contact without the need for adhesives. This self-fusing property occurs when the layers of the tape come into contact and progressively meld together to form a solid layer of insulation. The tape does not adhere to the surfaces upon which it is applied, making it an ideal choice for applications where conventional adhesive-backed tapes might fail.

Key Features

1. Durability Self-amalgamating electrical tape is designed to withstand extreme temperatures, moisture, and UV radiation. This durability makes it suitable for both indoor and outdoor use, ensuring reliable performance in various environmental conditions.

2. Electrical Insulation One of the primary roles of this tape is to provide electrical insulation. It prevents electrical shorts and protects wires from the elements, making it a crucial component in wiring repairs and installations.

3. Flexible and Stretchable The tape is highly flexible and can stretch significantly, which allows it to conform to a variety of shapes and surfaces. This feature enhances its versatility in applications where conventional tapes may not provide adequate coverage.

4. Chemical Resistance It exhibits resistance to many chemicals and solvents, which further extends its usefulness in industrial applications where exposure to harsh substances is a concern.

5. Easy Application Applying self-amalgamating tape is a straightforward process. Users simply need to stretch and wrap the tape around the area of concern, and it will fuse with itself to create a secure seal.

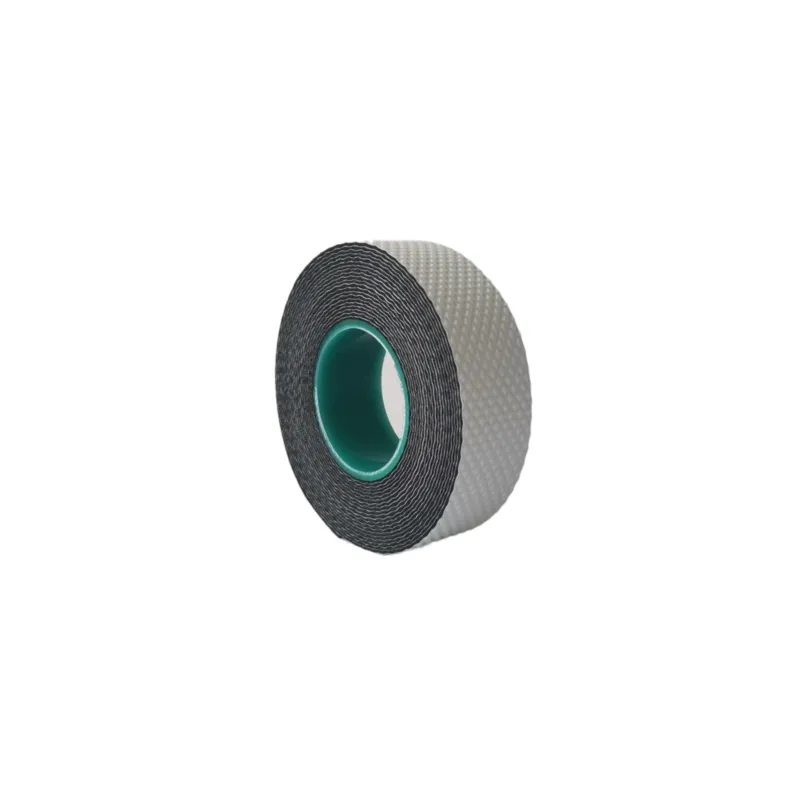

self amalgamating electrical tape

Applications

The applications of self-amalgamating electrical tape are extensive and varied. Here are some of the most common uses

1. Electrical Repairs It is widely used in the electrical industry for insulating and sealing connections, splices, and joints. The tape can be wrapped around exposed wires to prevent short circuits and protect against moisture ingress.

2. Automotive Industry In automotive repair and maintenance, self-amalgamating tape is ideal for insulating and sealing wiring harnesses, as well as providing protection against vibrations and environmental factors.

3. Aerospace and Marine Applications Given its resilience and resistance to extreme conditions, this tape is employed in aerospace and marine settings for insulating and securing electrical components subject to exposure to high levels of humidity and saltwater.

4. Plumbing Repairs It can also be utilized in plumbing to wrap around pipe joints and connections to prevent leaks — particularly useful in emergency situations where traditional methods might be impractical.

5. DIY Projects For hobbyists and DIY enthusiasts, self-amalgamating tape can be a handy tool for creative projects, crafting, and repairing household items.

Conclusion

Self-amalgamating electrical tape stands out as a multifunctional product that combines insulation properties with practicality. Its unique ability to bond to itself creates a waterproof, airtight seal, making it an indispensable material across various industries. Whether for professional electrical work, automotive repairs, or DIY projects, this tape offers a reliable solution that can withstand a multitude of conditions. As technology and materials continue to evolve, the applications and efficacy of self-amalgamating electrical tape are likely to expand even further, cementing its place as a cornerstone in both everyday fixes and critical applications.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025