Self-Amalgamating Rubber An Innovative Solution for Sealing and Insulation

In today's fast-paced industrial environment, the demand for efficient sealing and insulation materials is more crucial than ever. One such material that has gained popularity due to its unique properties is self-amalgamating rubber. This innovative product offers a range of advantages that make it an essential choice for various applications across different sectors, from electrical to automotive and beyond.

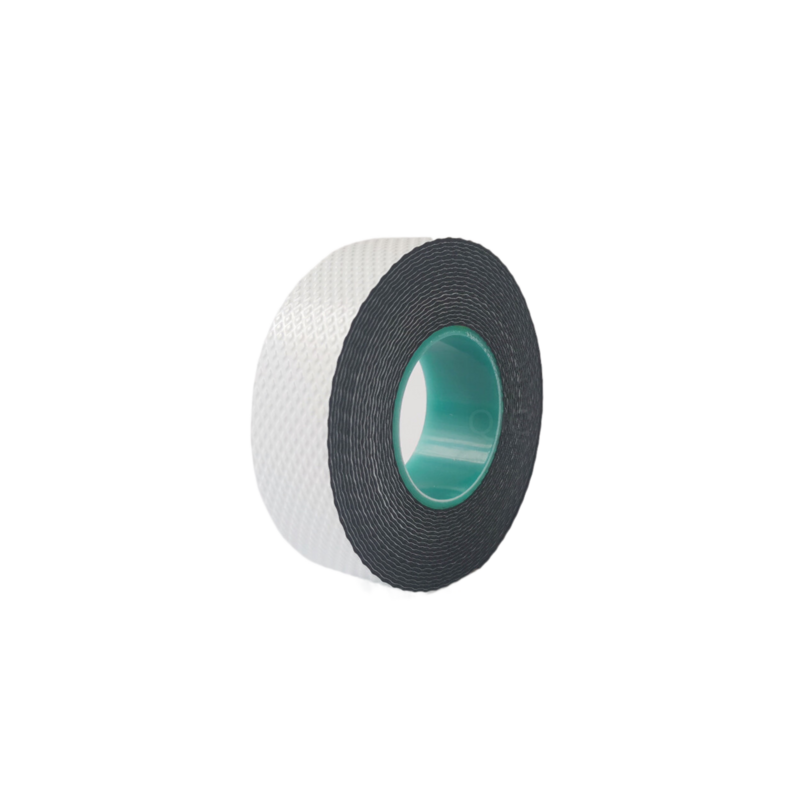

What is Self-Amalgamating Rubber?

Self-amalgamating rubber, often known as self-fusing rubber, is a synthetic rubber tape that can bond to itself without the need for adhesives or solvents. Unlike traditional tapes that may require additional substances for adhesion, self-amalgamating rubber utilizes a unique formulation that allows it to create a secure and long-lasting seal simply by overlapping layers. This characteristic makes it particularly useful in situations where a reliable, weatherproof seal is needed, such as in electrical wiring and connectors.

Key Features and Benefits

1. Excellent Insulation Properties One of the primary advantages of self-amalgamating rubber is its superb electrical insulation capabilities. It effectively prevents moisture and contaminants from interfering with electrical connections, significantly reducing the risk of short circuits and electrical failures.

2. Weather Resistance Self-amalgamating rubber is designed to withstand a variety of environmental conditions, including exposure to UV light, extreme temperatures, and humidity. This weather resistance ensures that the material maintains its integrity and performance over time, making it ideal for outdoor applications.

self amalgamating rubber

3. Easy Application The application process for self-amalgamating rubber is straightforward and does not require special tools. Users can easily wrap the material around the desired area, and it begins to bond immediately upon contact, forming a tight seal as layers are added. This ease of use is particularly beneficial in emergency situations where quick repairs are necessary.

4. Versatility This rubber tape is applicable across a range of sectors. In the electrical industry, it is frequently used for insulating and protecting wires, connectors, and other components. In the automotive industry, self-amalgamating rubber is employed to seal hoses and prevent leaks. Its versatile properties also make it suitable for plumbing, HVAC systems, and even for creating waterproof seals in various mechanical applications.

5. Durability Self-amalgamating rubber exhibits exceptional durability, proving resistant to wear and tear, punctures, and abrasions. This longevity reduces the need for frequent replacements, saving time and costs for businesses and individuals alike.

Applications in Various Industries

The unique characteristics of self-amalgamating rubber have led to its widespread adoption in multiple industries. For instance, in the telecommunications sector, it is used to protect sensitive cabling from environmental damage. In construction, it provides reliable sealing solutions for roofing and plumbing applications. Additionally, aviation and aerospace industries utilize self-amalgamating rubber to ensure the integrity of electrical systems in aircraft.

Conclusion

Self-amalgamating rubber is a remarkable innovation that offers effective sealing and insulation solutions across various applications. Its unique self-fusing properties, along with its durability, weather resistance, and ease of use, make it an essential tool for professionals in many fields. As industries continue to seek reliable and efficient materials, self-amalgamating rubber stands out as a dependable choice that meets and exceeds modern demands. With the ongoing advancements in technology and materials science, the future of self-amalgamating rubber looks bright, paving the way for even greater innovations in sealing and insulation solutions.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025