Self-Amalgamating Rubber A Versatile Solution for Sealing and Insulation

Self-amalgamating rubber has emerged as a pivotal material in various industrial applications, thanks to its unique properties and adaptability. This specialized rubber is designed to form a cohesive bond with itself, offering exceptional sealing and insulating capabilities, making it an invaluable resource in sectors like electrical, telecommunications, automotive, and construction.

At its core, self-amalgamating rubber is a type of elastomer that adheres to itself without the need for adhesives or curing agents. This characteristic allows the material to create a seamless, waterproof seal, which is critical in environments where moisture and dust ingress could potentially lead to equipment failure or degradation. The self-amalgamating process occurs when the rubber is stretched and then pressed against itself, enabling the molecules to link and form a solid, monolithic structure.

Self-Amalgamating Rubber A Versatile Solution for Sealing and Insulation

In the electrical industry, self-amalgamating rubber plays a crucial role in insulating cables and wires. Given the essential need for safety and reliability in electrical systems, this material is favored for personal safety equipment and high-voltage applications. The rubber’s ability to maintain flexibility and integrity under varying temperatures and conditions ensures that vital connections remain protected from the elements and mechanical wear.

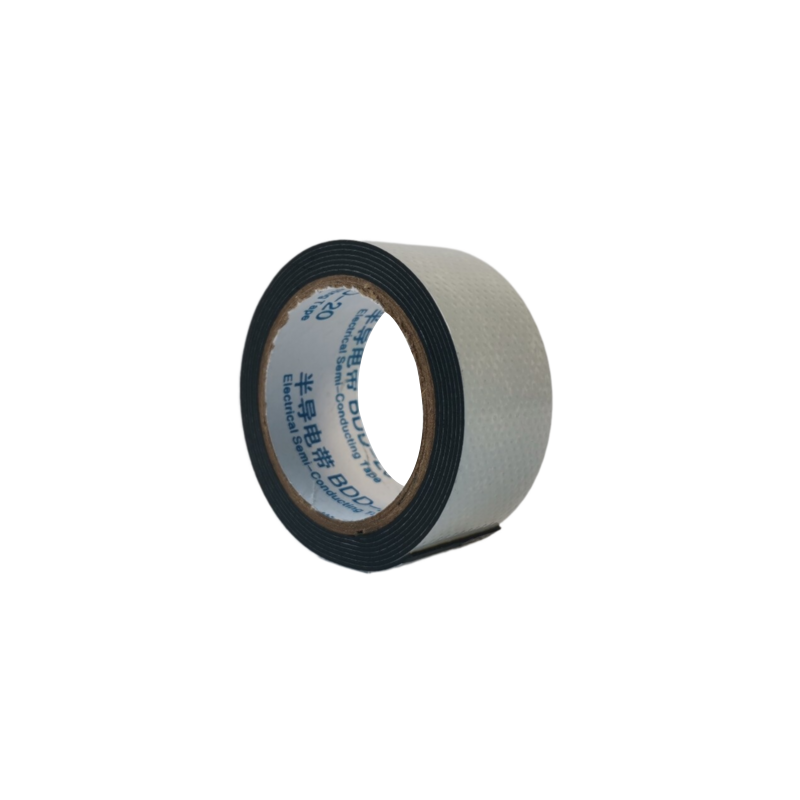

self amalgamating rubber

Moreover, self-amalgamating rubber finds extensive use in the telecommunications sector, where it is utilized to safeguard cable joints and protect sensitive equipment from moisture and environmental damage. Telecommunications installations often require rapid deployment in diverse weather conditions, and self-amalgamating rubber offers the flexibility needed to ensure reliable performance.

The automotive industry also benefits from the application of self-amalgamating rubber. It can be employed in various vehicle components, including electrical insulation, sound dampening, and vibration control. The rubber’s resistance to chemicals and oils further enhances its suitability for automotive applications, where exposure to fluids and varying environmental conditions is common.

In addition to its practical applications, the environmental aspect of self-amalgamating rubber cannot be overlooked. Many modern formulations are designed to be safe for the environment and can be recycled, contributing to sustainable practices within industries. As global standards for environmental responsibility continue to evolve, the demand for materials that offer both performance and eco-friendliness will only increase.

The versatility of self-amalgamating rubber extends beyond traditional applications. Its capacity for customization allows manufacturers to tailor formulations to meet specific performance requirements, such as varying degrees of flexibility, durability, and resistance to various environmental factors. This adaptability opens the door for even more innovative uses across diverse fields.

In conclusion, self-amalgamating rubber stands out as a highly effective solution for sealing and insulating needs across multiple industries. Its unique properties of self-bonding, ease of application, and durability make it an indispensable material in ensuring the reliability and longevity of equipment and infrastructure. As industries seek more efficient and sustainable solutions, the significance of self-amalgamating rubber will undoubtedly continue to grow.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025