Self-Amalgamating Rubber An Innovative Solution for Sealing and Insulation

Self-amalgamating rubber, often referred to as self-bonding rubber, is an innovative material widely employed in various industries due to its unique properties and versatile applications. Known for its excellent sealing and insulation capabilities, self-amalgamating rubber provides a reliable solution for a variety of bonding and sealing needs.

One of the key characteristics of self-amalgamating rubber is its ability to bond to itself without requiring any additional adhesives or curing agents. This self-amalgamation process occurs when the rubber is stretched and pressed together, allowing the material to fuse seamlessly. This feature not only simplifies the application process but also ensures a strong and durable bond that can withstand harsh environmental conditions.

Self-Amalgamating Rubber An Innovative Solution for Sealing and Insulation

One of the most common applications of self-amalgamating rubber is in electrical insulation. It is frequently used in electrical connections, cables, and splices to provide a moisture-proof seal that protects against corrosion and electrical failures. By using this rubber, electrical professionals can ensure the safety and reliability of their installations, reducing the risk of short circuits and other electrical hazards.

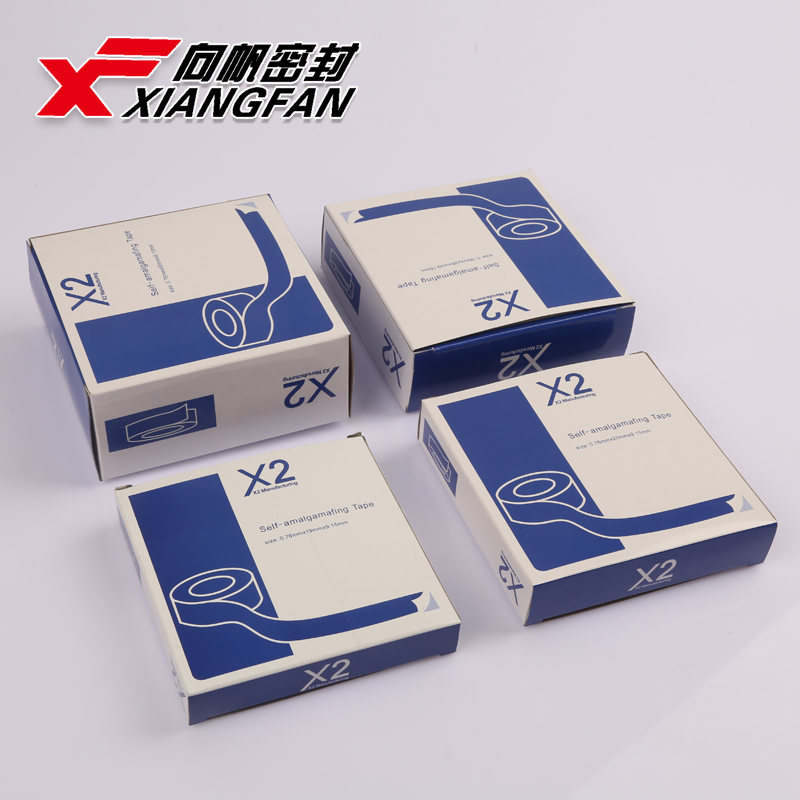

self amalgamating rubber

In addition to electrical applications, self-amalgamating rubber is also utilized in the automotive and aerospace industries. It can be used to insulate wires, protect sensitive components from moisture intrusion, and seal joints and seams in various structures. Its ability to conform to irregular shapes and surfaces makes it an ideal choice for complicated assemblies.

Another significant advantage of self-amalgamating rubber is its ease of application. The rubber is available in tapes and sheets, allowing for quick and efficient installation. Users can wrap or layer the material around pipes, cables, or other components with minimal preparation. This ease of use contributes to reduced labor costs and shorter project timelines.

Furthermore, self-amalgamating rubber contributes to sustainability efforts. Many manufacturers are now producing this material using environmentally friendly processes and components, reducing the overall ecological footprint. As industries increasingly focus on sustainable practices, self-amalgamating rubber plays a role in meeting these goals.

In conclusion, self-amalgamating rubber is a remarkable material that offers exceptional sealing and insulation properties, making it indispensable in various fields, including electrical, automotive, and aerospace applications. Its unique ability to bond to itself simplifies the installation process while providing robust protection against moisture and extreme conditions. As innovations continue to evolve in material science, self-amalgamating rubber is set to remain a critical component in ensuring the safety and efficiency of numerous industrial applications. Its combination of reliability, ease of use, and eco-friendliness positions it as a preferred choice for professionals across diverse sectors.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025