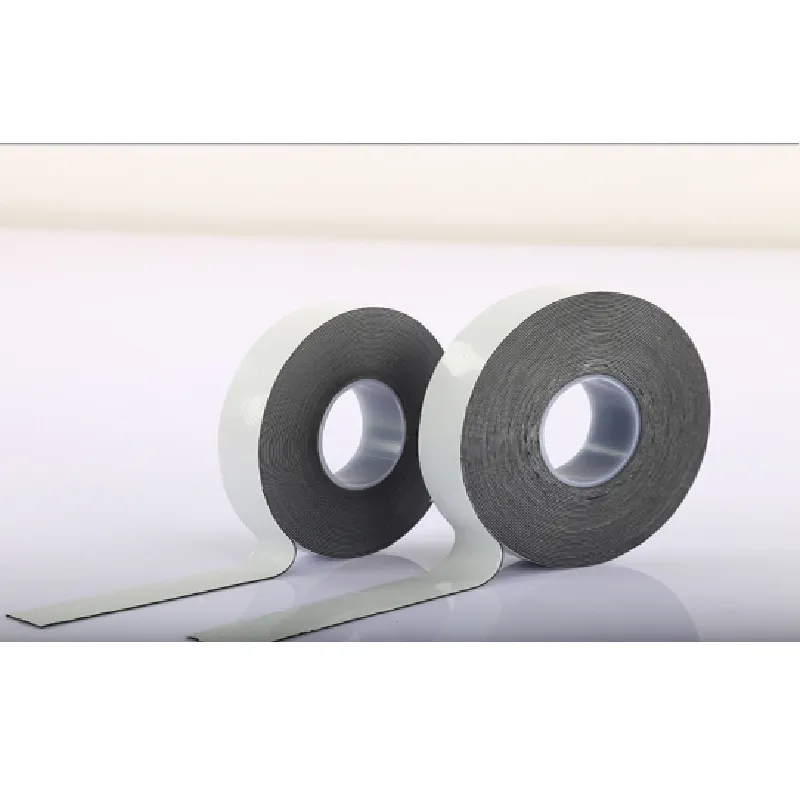

Self-Amalgamating Rubber Tape A Versatile Solution for Electrical and Repair Applications

In today's fast-paced world, the need for reliable and efficient solutions for electrical insulation and repair is more critical than ever. Among the various options available, self-amalgamating rubber tape, often referred to simply as amalgamating tape, has gained prominence for its unique properties and versatility. Specifically, black self-amalgamating rubber tape has become favored in numerous sectors, including electrical, automotive, and construction industries.

What is Self-Amalgamating Rubber Tape?

Self-amalgamating rubber tape is a type of adhesive tape made from a special rubber compound that allows the tape to bond to itself without the need for any additional adhesives or solvents. When stretched and applied, the tape fuses upon contact, creating an impermeable barrier. This feature makes it an excellent choice for waterproofing, insulation, and protection against external elements.

Key Features and Benefits

1. Water Resistance One of the most significant advantages of self-amalgamating rubber tape is its ability to repel water. This quality makes it ideal for electrical connections and repairs in environments exposed to moisture, ensuring long-lasting protection without degradation.

2. Flexibility and Versatility The tape is highly flexible, allowing it to conform to irregular shapes and surfaces. This adaptability makes it suitable for a wide range of applications, from bundling wires to providing protection on electrical components.

3. Temperature Resistance Black self-amalgamating rubber tape can typically withstand a broad range of temperatures, making it suitable for both indoor and outdoor use. This characteristic is especially important in electrical applications where temperature fluctuations are common.

4. UV Resistance The black color of the tape is not just aesthetic; it also provides a level of protection against UV rays. This is particularly beneficial for applications that will be exposed to sunlight, preventing degradation and ensuring the longevity of the material.

5. Electrical Insulation With a high dielectric strength, this tape is a superior alternative for electrical insulation. It effectively prevents electrical leakage and shorts, ensuring safety in various electrical applications.

Applications

The versatility of self-amalgamating rubber tape leads to its use in many practical applications

self amalgamating rubber tape black

- Electrical Repairs It is widely used in the electrical industry for insulating and repairing wires, terminals, and connectors. Its ability to create a strong, waterproof seal makes it preferable over conventional electrical tapes.

- Automotive Use Mechanics and automotive technicians often utilize this tape for various applications, including insulating wiring harnesses and repairing cracked hoses or cables

.- Construction and Manufacturing In the construction industry, the tape can be applied to protect and seal pipes, conduits, and other materials needing moisture resistance. Its robustness makes it suitable for demanding environments found in manufacturing plants.

Application Tips

To achieve the best results when using self-amalgamating rubber tape, proper application is essential

1. Prepare the Surface Ensure that the surface is clean, dry, and free of any debris before applying the tape. This will enhance adhesion and performance.

2. Stretch the Tape When applying, it is crucial to stretch the tape as it is wrapped around the surface. This action activates the self-amalgamating properties and ensures a tight bond.

3. Overlap Layers For added strength and protection, overlap each layer of tape by about half its width.

4. Press Firmly After wrapping, apply pressure to ensure that the tape amalgamates completely, forming a secure seal.

Conclusion

Black self-amalgamating rubber tape stands out as a reliable, versatile solution for a variety of applications, particularly in electrical insulation and repairs. Its unique properties, such as self-bonding, water resistance, and flexibility, offer a significant advantage over traditional tapes. As industries continue to seek efficient solutions for their needs, self-amalgamating rubber tape proves to be an essential tool in ensuring safety and durability in electrical and mechanical systems. Whether in the workshop, on the job site, or at home, this tape is undoubtedly worth having in your toolkit.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025