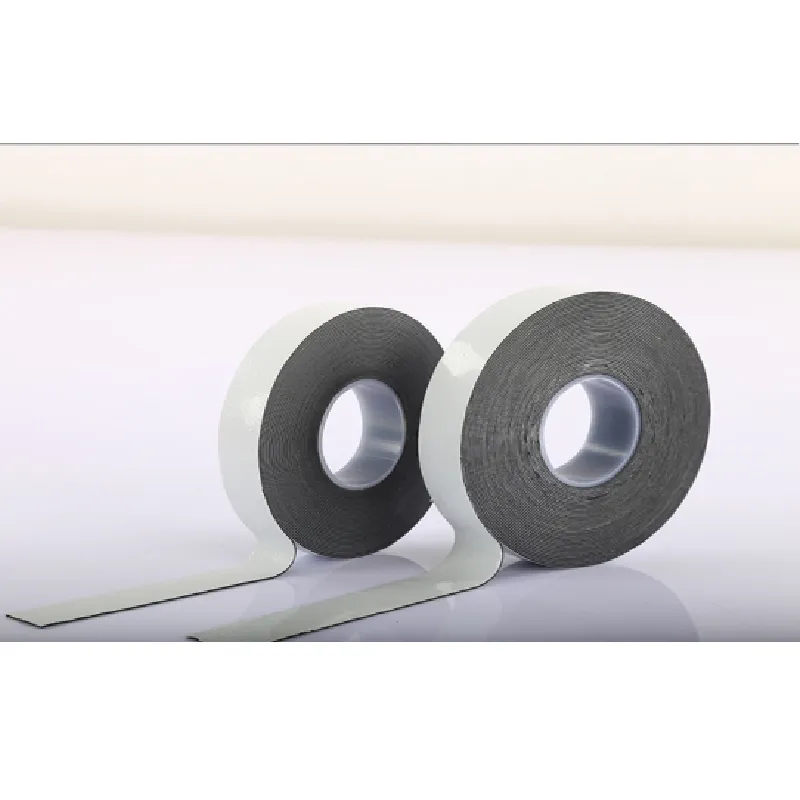

self amalgamating rubber tape black

Back to list

Jan . 14, 2025 10:39

Self-amalgamating rubber tape is a crucial component in various industries, known for its unique properties and versatility. Particularly in its black variant, this tape excels in applications that require durability, elasticity, and strong insulation.

From an expert's perspective, the key to maximizing the utility of black self-amalgamating rubber tape lies in its correct application. Ensuring that the tape is properly stretched during application is essential to activate the self-fusing property. Overlapping the tape by at least 50% as it is wrapped around an object guarantees a secure seal. Proper training and understanding of its application can significantly enhance efficiency and safety in professional settings. Therefore, the authoritative knowledge surrounding black self-amalgamating rubber tape is founded on its consistent performance across varied challenging scenarios. Industry veterans vouch for its reliability, as its engineering ensures adaptability and strength without compromising on quality. For those seeking a trustworthy solution in insulation, sealing, and repair, this tape is unparalleled. In conclusion, the adept use of black self-amalgamating rubber tape can vastly improve operational outcomes in numerous fields, owing to its profound benefits and durable nature. As industries continue to evolve, this tape remains an essential tool, demonstrating the importance of both expertise and experience in optimizing the efficiency and longevity of industrial and personal projects alike.

From an expert's perspective, the key to maximizing the utility of black self-amalgamating rubber tape lies in its correct application. Ensuring that the tape is properly stretched during application is essential to activate the self-fusing property. Overlapping the tape by at least 50% as it is wrapped around an object guarantees a secure seal. Proper training and understanding of its application can significantly enhance efficiency and safety in professional settings. Therefore, the authoritative knowledge surrounding black self-amalgamating rubber tape is founded on its consistent performance across varied challenging scenarios. Industry veterans vouch for its reliability, as its engineering ensures adaptability and strength without compromising on quality. For those seeking a trustworthy solution in insulation, sealing, and repair, this tape is unparalleled. In conclusion, the adept use of black self-amalgamating rubber tape can vastly improve operational outcomes in numerous fields, owing to its profound benefits and durable nature. As industries continue to evolve, this tape remains an essential tool, demonstrating the importance of both expertise and experience in optimizing the efficiency and longevity of industrial and personal projects alike.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025