The Rise of Self-Amalgamating Tape Suppliers An Essential Resource

In today's fast-paced industrial landscape, the demand for reliable, high-performance materials is paramount. One such product that has gained popularity across various sectors is self-amalgamating tape. Suppliers of this innovative tape have emerged as essential partners in ensuring the efficiency and safety of electrical and mechanical applications.

Understanding Self-Amalgamating Tape

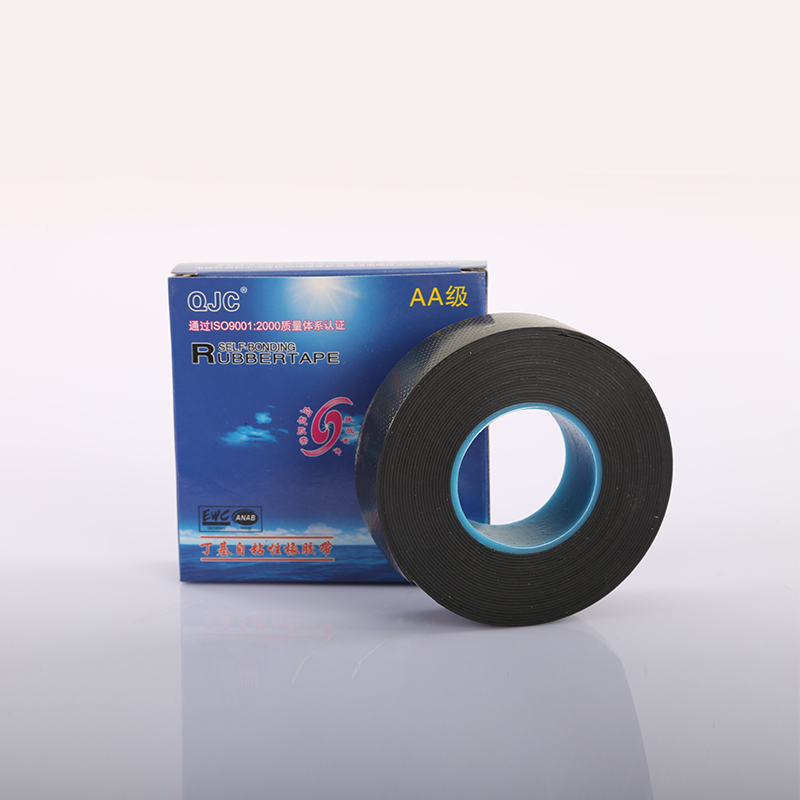

Self-amalgamating tape, also known as self-fusing or rubber tape, is a unique type of adhesive tape that does not require an adhesive backing. Instead, it adheres to itself through a process of amalgamation, where the tape's layers fuse together when stretched and wrapped around surfaces. This characteristic makes it ideal for applications where a watertight and air-tight seal is necessary. Commonly used in electrical insulation, bonding pipes, and protecting sports equipment, self-amalgamating tape has proven to be an indispensable resource.

The Market for Self-Amalgamating Tape

The global market for self-amalgamating tape has expanded significantly in recent years. As industries such as construction, automotive, and electronics grow, the need for high-quality sealing and insulating products has surged. Suppliers are stepping up to meet this demand, providing a variety of tapes with diverse properties to cater to specific applications. From varying thicknesses and width to color options and temperature resistance, today's self-amalgamating tapes are designed to fulfill a wide range of requirements.

Key Suppliers in the Industry

The landscape of self-amalgamating tape suppliers is diverse, comprising both large corporations and specialized manufacturers. Major players in the industry have established reputations for quality and reliability, often offering additional services such as customer education and product customization. Smaller suppliers may focus on niche markets, providing expert knowledge and tailored solutions that larger companies might overlook.

self amalgamating tape suppliers

Some key suppliers are renowned for their innovative approaches to product development. These companies invest heavily in research and development to produce durable tapes that can withstand extreme conditions, such as high temperatures or exposure to chemicals. This commitment to innovation ensures that industries relying on self-amalgamating tape have access to cutting-edge products that enhance their operational efficiency.

Quality Control and Standards

One of the most vital aspects of selecting a self-amalgamating tape supplier is understanding their quality control procedures. Reputable suppliers adhere to stringent quality standards and certifications, ensuring that their products meet industry expectations. This not only ensures the safety and effectiveness of the tape but also provides peace of mind to end-users who rely on the material in critical applications.

Furthermore, suppliers often engage in comprehensive testing of their tapes under various conditions to guarantee performance. This diligence helps to cultivate trust between suppliers and their clients, establishing long-term relationships based on reliability and consistency.

Sustainable Practices in the Industry

As environmental concerns become increasingly critical, many self-amalgamating tape suppliers are adopting sustainable practices in their manufacturing processes. This includes sourcing eco-friendly raw materials, minimizing waste, and implementing energy-efficient production methods. By prioritizing sustainability, these suppliers not only meet regulatory compliance but also appeal to environmentally-conscious consumers.

Conclusion

The role of self-amalgamating tape suppliers in modern industry cannot be overstated. With a growing market, diverse product offerings, and a commitment to quality and sustainability, these suppliers are invaluable resources for businesses across various sectors. As innovation continues to drive product development, the future of self-amalgamating tape is bright, promising even greater applications and advancements in sealing and insulating technology. Whether for electrical, mechanical, or protective purposes, the reliability of self-amalgamating tape remains a key factor in enhancing operational efficiency and safety in today’s competitive landscape.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025