Self-Amalgamating Tape A Comprehensive Overview on Temperature Resistance

In the realm of electrical insulation and protection, self-amalgamating tape has garnered significant attention for its unique properties and versatile applications. One of the critical factors to consider when using this type of tape is its temperature resistance. Understanding how self-amalgamating tape behaves under varying thermal conditions is crucial for ensuring the reliability and longevity of electrical systems.

What is Self-Amalgamating Tape?

Self-amalgamating tape, also known as self-fusing or silicone tape, is a type of adhesive tape that is made from a coated rubber or silicone material. Unlike traditional tapes that rely on adhesives to stick to surfaces, self-amalgamating tape bonds to itself when stretched and wrapped around objects. This self-fusion process creates a solid, waterproof seal that is exceptionally durable and protects against environmental factors such as moisture, dust, and chemicals.

Temperature Resistance

The temperature resistance of self-amalgamating tape varies depending on its composition. Typically, these tapes can withstand temperatures ranging from -40°C to 130°C (-40°F to 266°F), making them suitable for a wide array of applications. Some specialized variants can resist even higher temperatures, reaching up to 200°C (392°F) for short durations. The combination of heat resistance and durability makes self-amalgamating tape an ideal choice for automotive, marine, and industrial applications where temperature fluctuations are common.

Benefits of Temperature Resistance

The ability to resist high temperatures without losing its integrity is one of the most significant advantages of self-amalgamating tape. In electrical applications, heat can lead to softening and melting of traditional adhesives, causing failure in insulation. However, self-amalgamating tape maintains its form and functionality under temperature stress, providing reliable protection for wires and cables. This feature is particularly important in environments that experience thermal expansion and contraction, where traditional tapes might fail.

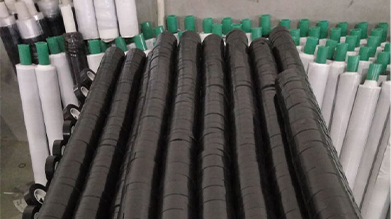

self amalgamating tape temperature

Moreover, in automotive and aerospace contexts, components are often exposed to extreme temperatures and fluctuating conditions. Self-amalgamating tape can be utilized in these scenarios to ensure that electrical connections remain secure and protected from heat-related degradation. Its flexibility allows it to conform to the shape of various components, ensuring comprehensive coverage and protection.

Application Scenarios

Self-amalgamating tape can be widely applied in various industries. In construction, it protects electrical wires in harsh environments where moisture and heat are prevalent. In the automotive sector, it is used to insulate and protect critical components, such as battery connections and wiring harnesses, from temperature extremes. Marine applications benefit from the tape's water-resistant properties, as it provides an added layer of security for electrical and electronic systems exposed to sea conditions.

Additionally, the tape is advantageous for DIY projects and repairs. Its ease of use means that individuals can quickly wrap and seal electrical connections without the need for professional assistance. The self-fusing characteristic eliminates the need for messy adhesives or additional tools, streamlining the repair process.

Limitations and Considerations

While self-amalgamating tape is incredibly effective in many scenarios, it is not without limitations. For instance, the tape should not be used as a substitute for permanent electrical insulation in places where it must withstand prolonged contact with high voltages or in situations where it may be exposed to direct UV light for extended periods. Moreover, while it can resist higher temperatures, prolonged exposure to temperatures at the upper limits of its resistance can lead to deterioration over time.

Conclusion

Self-amalgamating tape stands out for its superior temperature resistance and versatility in various applications. With the ability to withstand extreme conditions while providing a reliable seal and protection, it is an invaluable material in many industries. As technology evolves and the demand for resilient materials increases, self-amalgamating tape is likely to remain a staple for electrical insulation and beyond. Understanding its properties, including its temperature resistance, equips users to make informed decisions, ensuring safety and efficiency in their applications.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025