Self-Amalgamating Tape The Ultimate Waterproof Solution

In an age where reliability and durability are paramount, many have turned to innovative materials to solve everyday problems. One such remarkable product that stands out is self-amalgamating tape, particularly its waterproof variation. This tape, primarily made from elastomeric materials, boasts unique properties that allow it to bond to itself seamlessly, resulting in a strong, watertight seal that is particularly advantageous in various applications.

What is Self-Amalgamating Tape?

Self-amalgamating tape, also known as self-fusing or self-bonding tape, is a specialized tape that does not adhere to surfaces but rather fuses to itself. When stretched and wrapped around an object, it creates a solid, rubber-like bond without the need for adhesives or additional fasteners. This unique self-amalgamating property allows the tape to conform to irregular shapes and surfaces, making it ideal for a range of applications where conventional tapes might fall short.

Waterproof Qualities

The waterproof characteristics of self-amalgamating tape make it a versatile solution for various environmental conditions. Whether you are sealing a leaky pipe, protecting electrical connections, or waterproofing outdoor equipment, this tape provides a reliable barrier against moisture. Its impermeability helps prevent water ingress, which can lead to corrosion, electrical failures, and other damage. This quality is particularly crucial for those in industries like construction, marine, automotive, and outdoor recreation, where exposure to water is a significant concern.

Applications Across Industries

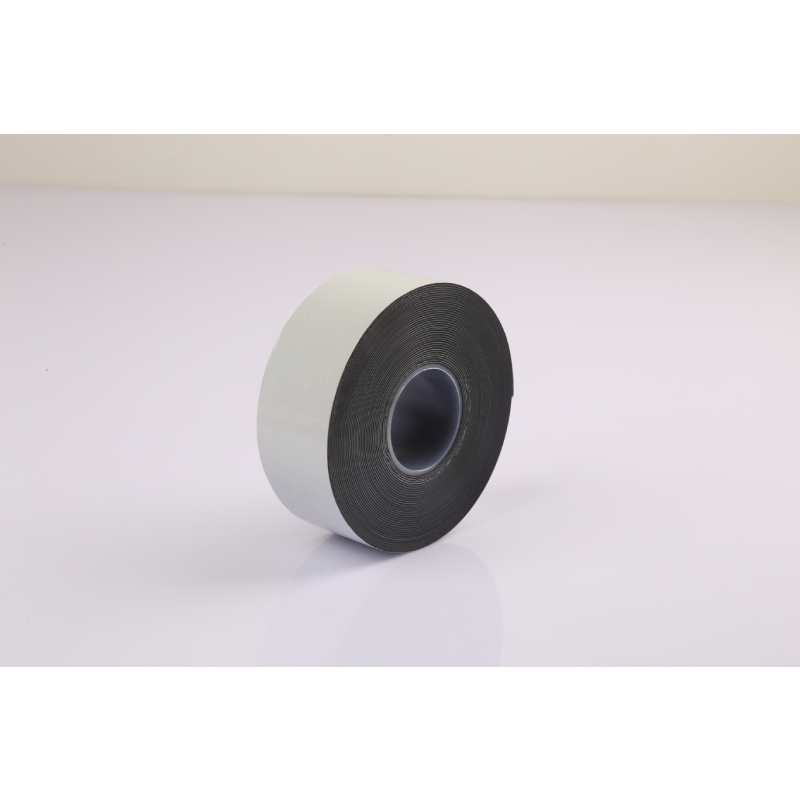

self amalgamating tape waterproof

Self-amalgamating tape is not limited to any single use; its versatility knows no bounds. In plumbing, for instance, it can be swiftly applied to leaking pipes or fittings to provide a temporary fix until a permanent solution can be implemented. Electricians often utilize this tape to insulate and protect electrical wires and connections, ensuring that moisture does not compromise safety or functionality.

In the automotive sector, self-amalgamating tape is frequently used to repair hoses, electrical components, and even as a protector for bodywork against scratches and abrasions. Outdoor enthusiasts appreciate its ability to seal tents, mountaineering gear, and fishing equipment, ensuring that activities remain uninterrupted by unexpected water exposure.

Easy Application and Environmentally Friendly

One of the most significant advantages of self-amalgamating tape is its ease of use. Unlike traditional tapes that can be cumbersome and require precise application, this tape can be applied in a matter of seconds. Users simply stretch the tape and wrap it around the desired surface, and within minutes, the tape bonds to itself, forming a robust seal. This no-mess application makes it a go-to option for quick repairs on the go.

Moreover, many self-amalgamating tapes are made from environmentally friendly materials, further enhancing their appeal. Unlike some other waterproofing solutions that contain harmful chemicals, self-amalgamating tapes can be a safer choice for both users and the environment.

Conclusion

Self-amalgamating tape is revolutionizing the way we approach waterproofing and sealing applications. Its unique ability to bond to itself, combined with its waterproof properties, makes it an ideal solution for both temporary repairs and long-term applications across various industries. With ease of use and environmental considerations, self-amalgamating tape stands out as an innovative solution that is both practical and reliable, making it an invaluable addition to any toolbox. Whether you are a DIY enthusiast or a professional tradesperson, having self-amalgamating tape on hand can save you time, money, and hassle in your repair endeavors.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025