Self-Annealing Tape The Future of Electrical Insulation and Repair

In today's fast-paced technological environment, innovation is the driving force behind efficient and effective solutions to everyday problems. One such innovation is self-annealing tape, a revolutionary product that is changing the landscape of electrical insulation and repair. This versatile tape combines several remarkable attributes, making it a valuable asset across many industries, from electrical engineering to automotive repair and beyond.

What is Self-Annealing Tape?

Self-annealing tape is a type of thermoplastic tape, primarily designed for electrical insulation and protective applications. Its unique feature lies in its ability to bond with itself upon application of heat and pressure. Unlike traditional adhesive tapes that primarily rely on sticky surfaces to adhere to objects, self-annealing tape creates a durable and robust bond through a process called thermoplastic flow. When heated, the tape becomes pliable, allowing it to envelop the surfaces it contacts tightly, creating a seamless and secure insulation layer.

Key Features and Benefits

1. High Insulation Properties One of the standout features of self-annealing tape is its excellent electrical insulation properties. This makes it an ideal choice for electrical applications, as it can effectively prevent short circuits and electrical leaks. The high dielectric strength enables it to handle high-voltage applications, ensuring the safety and longevity of electrical components.

2. Self-Fusing Capabilities The self-fusing property of the tape offers unique advantages over conventional tapes. When two ends of the tape are joined, they fuse together, resulting in a continuous, void-free insulation layer. This is particularly useful in environments where moisture, dirt, or other contaminants can compromise the integrity of the insulation.

3. Versatility Self-annealing tape is not limited to electrical applications alone. It has found its place in various industries, including automotive, aerospace, telecommunications, and even home improvement projects. Its ability to adapt to different surfaces and structures makes it a go-to solution for multiple repair and insulation needs.

4. Temperature Resistance This type of tape is engineered to withstand high temperatures, making it suitable for applications that experience thermal stress. The tape can often maintain its integrity even in extreme conditions, which is essential for industries operating in harsh environments.

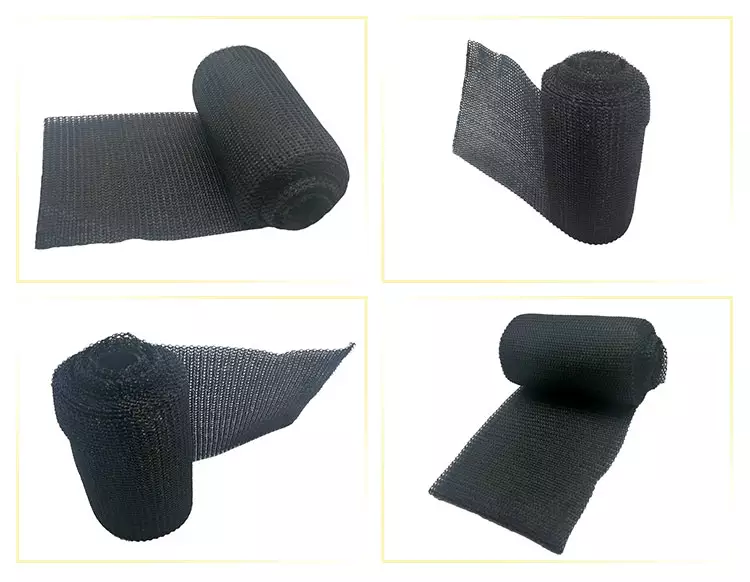

self annealing tape

5. Ease of Use Self-annealing tape is user-friendly and requires no specialized tools for application. It can be easily cut to any length and wrapped around components with minimal effort. Moreover, the quick fusing feature means repairs can be completed swiftly, reducing downtime in industrial settings.

6. Aesthetics In addition to its functional attributes, self-annealing tape often comes in a variety of colors and finishes. This allows users to not only focus on the performance but also the visual appeal, especially in applications where exposed elements are part of the design.

Applications

- Electrical Insulation Self-annealing tape is ideal for insulating wire splices, connectors, and other electrical components, ensuring safety and efficiency in installations. - Automotive Repairs The tape can be used for wiring repairs, insulation against moisture, and even as a protective layer on engine components.

- Telecommunications In telecom installations, the tape serves as a protective barrier for sensitive wiring and equipment, guarding against environmental factors.

- Home Improvement For DIY enthusiasts, self-annealing tape offers a reliable solution for various repair tasks, from plumbing to electrical work, providing both utility and enduring results.

Conclusion

Self-annealing tape represents a significant evolution in the realm of insulation and repair solutions. With its exceptional insulation properties, self-fusing capabilities, and versatility across multiple applications, it is poised to become an indispensable tool in both professional and DIY settings. As industries continue to embrace new technologies, products like self-annealing tape will undoubtedly play a crucial role in enhancing safety, efficiency, and quality of work across the board. The future of electrical fixation and repair has arrived, and self-annealing tape is leading the charge.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025