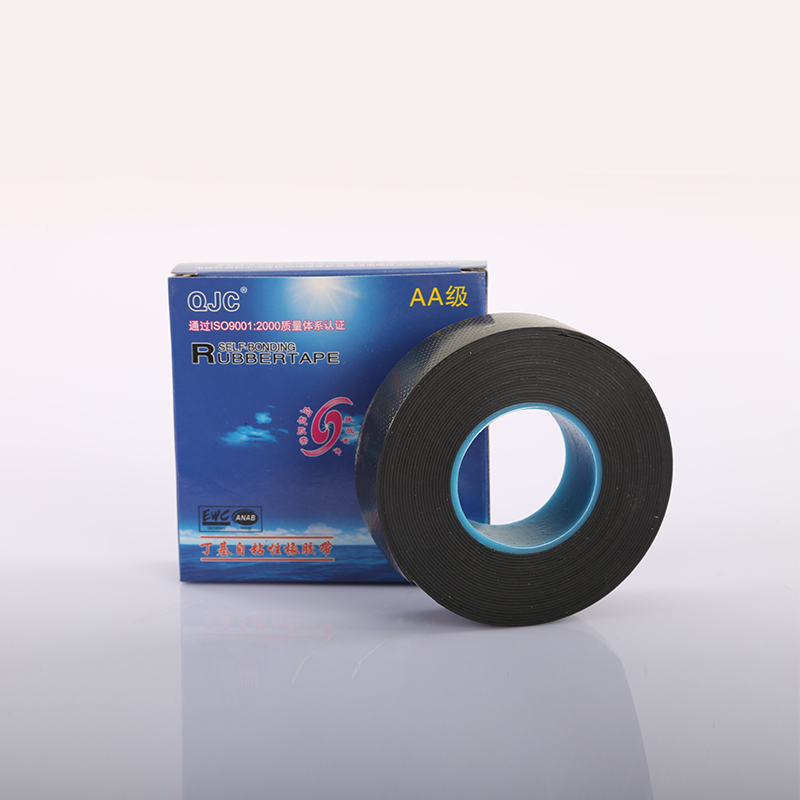

flex tape waterproof tape

Back to list

Feb . 11, 2025 02:57

Self-fusing rubber tape is more than just an adhesive solution; it's a game-changer in the world of repairs and insulation. This versatile tool has revolutionized the way both professionals and DIY enthusiasts approach a variety of tasks, providing unmatched sealing and insulation properties without the need for heat or glue. The moment you stretch and apply it, the tape's inherent elasticity and material composition allow it to bond with itself, creating an impermeable seal that's resistant to water, oil, acid, and even UV light. This article explores the real-life experiences, professional expertise, and authoritative trust in using self-fusing rubber tape.

Trust in self-fusing rubber tape is underscored by its military and aerospace applications. These industries demand the highest standards of reliability and resilience. The tape's robust sealing mechanisms and its resistance to extreme environmental conditions make it a staple in these fields. When considering the safety of equipment and personnel, the importance of materials that can stand the test of time cannot be overstated, providing peace of mind to engineers and officials who authorize its use. From a DIY perspective, anyone looking to tackle home improvement projects can count on self-fusing rubber tape for various tasks—from garden hose leaks to air conditioning unit repairs. The simplicity of its application—requiring no special tools—enables homeowners to address issues effectively, enhancing their homes' safety and efficiency. Overall, what makes self-fusing rubber tape stand out is not just the raw functionality it offers but the trust it has earned across many sectors. Professionals and hobbyists alike find its blend of convenience, durability, and effectiveness unmatched. As the demand for efficient, reliable, and versatile products grows, self-fusing rubber tape continues to prove its worth, solidifying its position as an essential tool across multiple disciplines.

Trust in self-fusing rubber tape is underscored by its military and aerospace applications. These industries demand the highest standards of reliability and resilience. The tape's robust sealing mechanisms and its resistance to extreme environmental conditions make it a staple in these fields. When considering the safety of equipment and personnel, the importance of materials that can stand the test of time cannot be overstated, providing peace of mind to engineers and officials who authorize its use. From a DIY perspective, anyone looking to tackle home improvement projects can count on self-fusing rubber tape for various tasks—from garden hose leaks to air conditioning unit repairs. The simplicity of its application—requiring no special tools—enables homeowners to address issues effectively, enhancing their homes' safety and efficiency. Overall, what makes self-fusing rubber tape stand out is not just the raw functionality it offers but the trust it has earned across many sectors. Professionals and hobbyists alike find its blend of convenience, durability, and effectiveness unmatched. As the demand for efficient, reliable, and versatile products grows, self-fusing rubber tape continues to prove its worth, solidifying its position as an essential tool across multiple disciplines.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025