Understanding the Importance of Shop Floor Tape in Manufacturing Environments

In the bustling world of manufacturing and industrial settings, organization and safety are paramount. One of the often-overlooked yet crucial tools to achieve these goals is shop floor tape. These brightly colored adhesive tapes serve multiple purposes, enhancing workflow, maximizing safety, and fostering a more efficient working environment.

What is Shop Floor Tape?

Shop floor tape, also known as floor marking tape, is a specialized type of tape designed to be applied to the floor of a workshop, factory, or any workspace. It typically comes in a variety of colors and widths, allowing facilities to create a customized marking system based on their unique needs. The taping system can designate walkways, equipment zones, storage locations, or hazardous areas, and its visibility helps convey essential information at a glance.

Enhancing Safety

One of the primary reasons organizations use shop floor tape is to improve safety within the workplace. By clearly marking pathways, exit routes, and hazardous zones, the tape helps reduce accidents and injuries among employees. For example, brightly colored tape can signal to workers where they should walk to avoid heavy machinery or other potentially dangerous equipment. This kind of visual guidance is vital, especially in busy environments where distractions are common.

Additionally, using shop floor tape to define areas can ensure that employees maintain a safe distance from equipment or materials that could pose risks. By creating designated zones for walking, working, and storage, companies can minimize the likelihood of collisions or accidents during busy operations.

Boosting Efficiency and Productivity

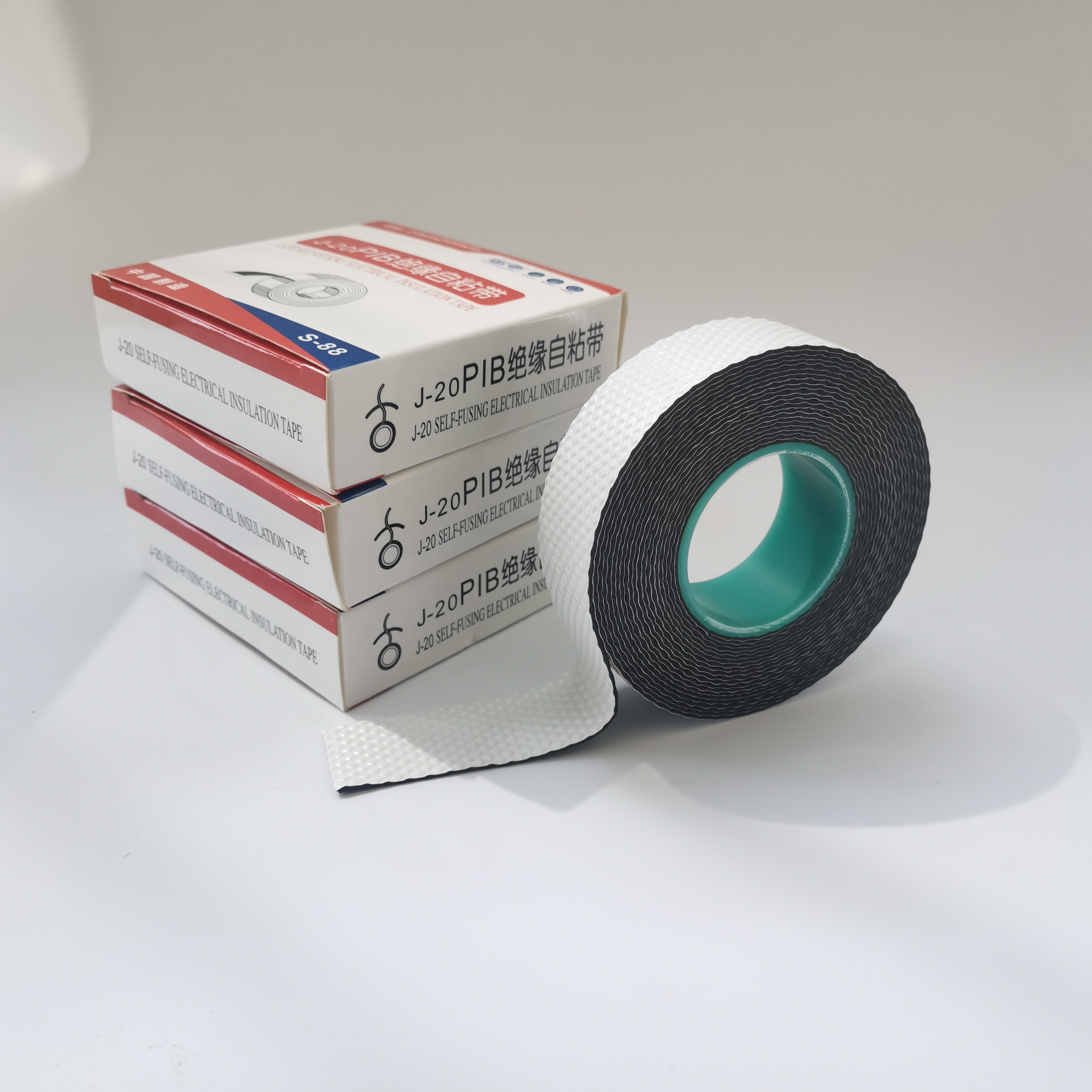

shop floor tape

In any manufacturing environment, time is money. When employees have to navigate cluttered, unmarked spaces, it can slow down workflow and reduce overall productivity. Shop floor tape can streamline operations by defining specific areas for different tasks or materials. For instance, a clearly marked area for tools and equipment means employees can quickly find what they need without wasting time searching.

Moreover, with a clear layout in place, new employees or visitors can quickly acclimate to the workspace, leading to faster onboarding and reduced downtime. The visual nature of floor tape also helps keep areas organized, as it encourages workers to return tools and materials to their designated locations rather than leaving them scattered about.

Facilitating Lean Manufacturing Principles

Incorporating shop floor tape into a manufacturing facility aligns well with lean manufacturing principles. Lean methodologies emphasize minimizing waste, maximizing value, and improving processes. By marking areas and pathways clearly, shop floor tape can help identify inefficiencies and facilitate continuous improvements.

For instance, if an area is consistently cluttered or underutilized, the visibility provided by shop floor tape can prompt discussions on how to optimize that space for better workflow. This not only encourages a culture of efficiency but also empowers employees to take ownership of their workspace.

Conclusion

Shop floor tape may seem like a simple tool, but its impact on workplace safety, efficiency, and organization is profound. By investing in high-quality floor marking tape and developing a clear marking system tailored to the specific needs of a facility, companies can enhance both safety and productivity. As industries continue to evolve and grow, so too will the importance of implementing effective organizational strategies like shop floor tape to navigate the complexities of modern manufacturing environments. Adopting this simple yet effective solution can ultimately lead to a safer, more productive, and more organized workspace.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025