splicing tape

Back to list

Jan . 13, 2025 12:42

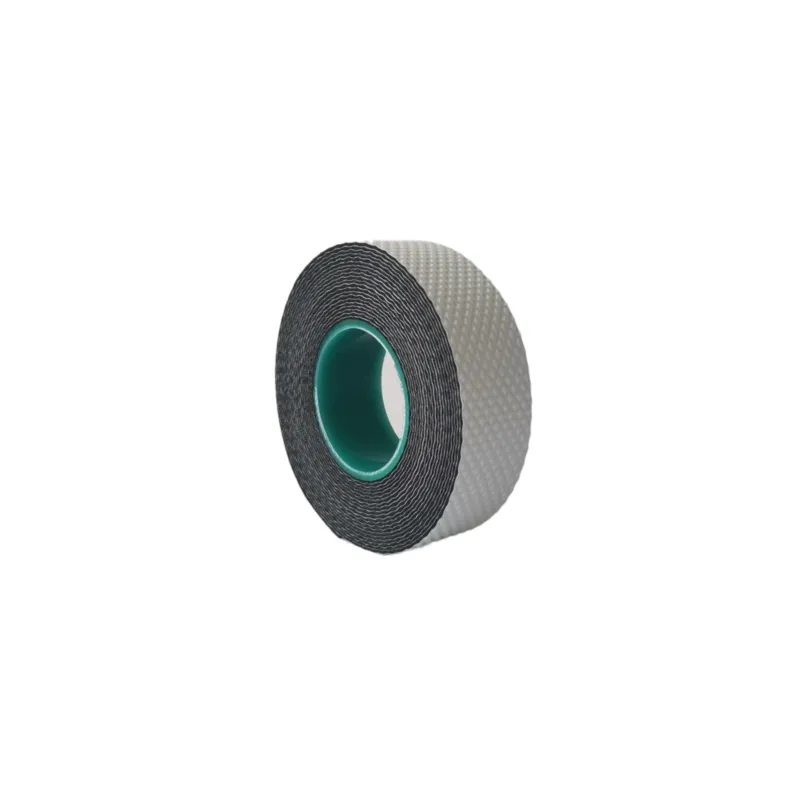

For professionals working with electrical systems, ensuring the reliability and safety of connections under high voltage conditions is paramount. High voltage splicing tape is specifically designed to meet these demanding criteria, providing robust insulation and protection in extreme environments. This article sheds light on its unique features, practical applications, and installation best practices that enhance its effectiveness and ensure optimal performance.

For those responsible for installing high voltage splicing tape, proper technique is crucial. The installation involves wrapping the tape to achieve uniform tension, ensuring that layers overlap by 50% for a tight seal. This technique maximizes the tape's insulating properties while minimizing potential air gaps. It is also advisable to perform regular inspections and maintenance checks on taped areas to preempt any potential issues, particularly in environments subject to extreme weather conditions or heavy mechanical use. One of the major advantages of high voltage splicing tape lies in its proven track record among industry experts and seasoned electricians who vouch for its reliability and performance. Product certifications and rigorous testing further underline its authority and trustworthiness within the electrical sector. Manufacturers often provide extensive technical guides and support, underscoring their commitment to quality and assisting customers in selecting the right tape for specific applications. This attentive customer service, combined with user testimonials and case studies, enhances the product's credibility and reputation. Ultimately, choosing high voltage splicing tape is not just about selecting insulation material; it's about making a commitment to safety, efficiency, and long-term cost savings. By investing in high-quality tapes and employing skilled installation techniques, businesses can significantly reduce the likelihood of electrical failures, ensuring uninterrupted operation and compliance with safety regulations. As innovation continues to drive advancements in material science, experts anticipate even more reliable and efficient solutions to emerge, further solidifying the role of high voltage splicing tape in safeguarding electrical infrastructures globally.

For those responsible for installing high voltage splicing tape, proper technique is crucial. The installation involves wrapping the tape to achieve uniform tension, ensuring that layers overlap by 50% for a tight seal. This technique maximizes the tape's insulating properties while minimizing potential air gaps. It is also advisable to perform regular inspections and maintenance checks on taped areas to preempt any potential issues, particularly in environments subject to extreme weather conditions or heavy mechanical use. One of the major advantages of high voltage splicing tape lies in its proven track record among industry experts and seasoned electricians who vouch for its reliability and performance. Product certifications and rigorous testing further underline its authority and trustworthiness within the electrical sector. Manufacturers often provide extensive technical guides and support, underscoring their commitment to quality and assisting customers in selecting the right tape for specific applications. This attentive customer service, combined with user testimonials and case studies, enhances the product's credibility and reputation. Ultimately, choosing high voltage splicing tape is not just about selecting insulation material; it's about making a commitment to safety, efficiency, and long-term cost savings. By investing in high-quality tapes and employing skilled installation techniques, businesses can significantly reduce the likelihood of electrical failures, ensuring uninterrupted operation and compliance with safety regulations. As innovation continues to drive advancements in material science, experts anticipate even more reliable and efficient solutions to emerge, further solidifying the role of high voltage splicing tape in safeguarding electrical infrastructures globally.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025