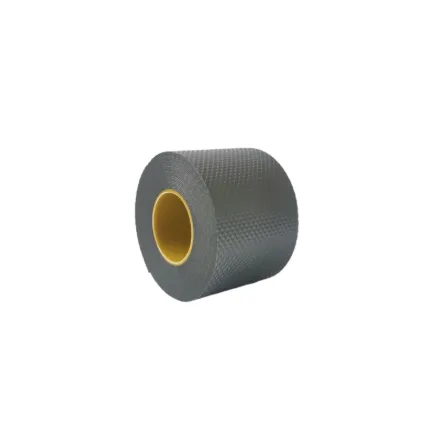

J50 High-voltage EPR Rubber Tape

Back to list

Feb . 12, 2025 14:24

Splicing tape, a critical component in various industries, often goes unnoticed despite its significant role in ensuring seamless operations. This seemingly simple tool is an unsung hero in sectors ranging from manufacturing to film production. With years of experience in industrial applications, I’ve seen firsthand the transformative power of the right splicing tape in various settings.

From a technical standpoint, the importance of understanding adhesive types used in splicing tapes cannot be overstated. Acrylic adhesives, known for their excellent environmental resistance, are ideal for long-term durability and performance. In contrast, rubber adhesives might offer better immediate tack but may sacrifice longevity. Knowing the right adhesive type for the application ensures not only efficiency but also cost-effectiveness in operations. Expert knowledge in the application and utility of splicing tape can significantly impact operational success. With proper training, personnel can execute effective splicing, reducing waste and enhancing overall productivity. Many suppliers offer workshops and training sessions as part of their service packages, highlighting their commitment to long-term client satisfaction. In terms of trustworthiness, selecting a splicing tape supplier with a track record for quality and reliability is paramount. Reviews and case studies from established clients can provide insight into the supplier's expertise and the tape's performance in real-world applications. Partnering with an experienced supplier means benefitting from their vast understanding of industry nuances and access to the latest technologies in tape production. In conclusion, while splicing tape might appear as a minor detail in industrial applications, its impact is profound. Whether for maintaining the integrity of a production line, ensuring the seamlessness of a film edit, or achieving smooth printing processes, the right splicing tape becomes an essential tool. Emphasizing experience, expertise, and trustworthiness helps guarantee that operations remain uninterrupted, efficient, and successful over the long term.

From a technical standpoint, the importance of understanding adhesive types used in splicing tapes cannot be overstated. Acrylic adhesives, known for their excellent environmental resistance, are ideal for long-term durability and performance. In contrast, rubber adhesives might offer better immediate tack but may sacrifice longevity. Knowing the right adhesive type for the application ensures not only efficiency but also cost-effectiveness in operations. Expert knowledge in the application and utility of splicing tape can significantly impact operational success. With proper training, personnel can execute effective splicing, reducing waste and enhancing overall productivity. Many suppliers offer workshops and training sessions as part of their service packages, highlighting their commitment to long-term client satisfaction. In terms of trustworthiness, selecting a splicing tape supplier with a track record for quality and reliability is paramount. Reviews and case studies from established clients can provide insight into the supplier's expertise and the tape's performance in real-world applications. Partnering with an experienced supplier means benefitting from their vast understanding of industry nuances and access to the latest technologies in tape production. In conclusion, while splicing tape might appear as a minor detail in industrial applications, its impact is profound. Whether for maintaining the integrity of a production line, ensuring the seamlessness of a film edit, or achieving smooth printing processes, the right splicing tape becomes an essential tool. Emphasizing experience, expertise, and trustworthiness helps guarantee that operations remain uninterrupted, efficient, and successful over the long term.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025