The Importance of Strip Seal Technology in Modern Applications

In today’s rapidly advancing technological landscape, the significance of effective sealing solutions cannot be overstated. Among various sealing techniques, strip seals stand out for their versatile applications and essential role in ensuring the integrity, efficiency, and safety of numerous systems. From automotive industries to construction and aerospace, strip seals have become an indispensable component.

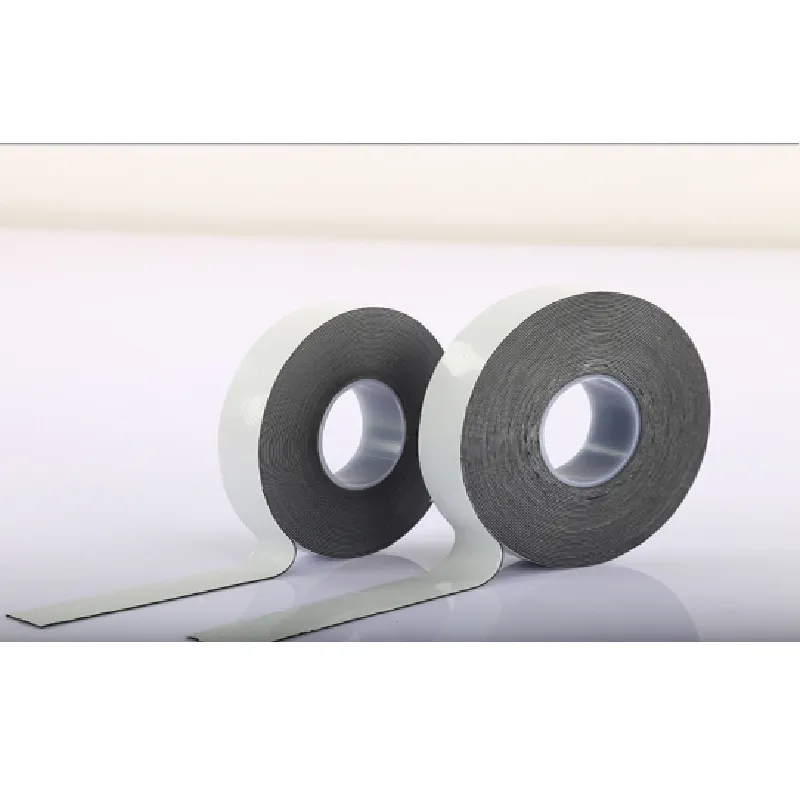

At its core, a strip seal is specifically designed to create a barrier that prevents the leakage of gases, liquids, and other substances. Typically made from materials like rubber or silicone, these seals are customized to fit precisely within designated grooves or channels, ensuring a snug fit that can withstand a variety of environmental conditions. Their primary function is to maintain pressure, minimize contamination, and enhance the longevity of the components they protect.

One of the leading applications of strip seals is within the automotive sector

. Engines, transmissions, and differentials require robust sealing solutions that can withstand high temperatures and pressures. Strip seals play a crucial role in preventing fluid leaks, thereby enhancing fuel efficiency and overall vehicle performance. The automotive industry increasingly relies on innovative strip seal designs, which contribute to the development of lightweight yet durable vehicles.strip seal

Moreover, strip seals are vital in construction applications, particularly in door and window fittings. They provide thermal insulation, reduce noise transmission, and prevent water infiltration—all of which are essential for creating comfortable and energy-efficient living spaces. As building standards become more stringent regarding energy efficiency, the demand for high-performance strip seals in both residential and commercial structures continues to grow.

The aerospace industry also benefits significantly from strip seal technology. Aircraft require sealing solutions that can withstand extreme pressures and temperatures during flight. Strip seals help ensure that vital systems—such as fuel lines and hydraulic systems—operate safely and efficiently, reducing the risk of catastrophic failures. As the sector moves towards more sustainable practices, the emphasis on reliable sealing solutions is more important than ever.

In addition to their practical applications, strip seals are increasingly being recognized for their role in sustainability. As industries seek ways to minimize waste and improve energy efficiency, the reliability of strip seals means reduced maintenance and longer lifespans for machinery and structures. This, in turn, leads to less environmental impact over time.

In conclusion, strip seals are a vital component across multiple industries, providing effective sealing solutions that enhance performance, safety, and sustainability. As technology continues to evolve, the demand for advanced strip seal designs will only increase. By improving the integrity of systems and contributing to energy efficiency, strip seals will remain a key player in driving innovation across various sectors.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025