The Role of PVC Electrical Tape Manufacturers in Industry and DIY Applications

PVC electrical tape, a staple in both industrial and domestic electrical work, plays a significant role in ensuring safety and reliability in electrical applications. As the demand for high-quality electrical components continues to grow, the role of PVC electrical tape manufacturers has become increasingly vital. This article explores the importance of PVC electrical tape, the manufacturing process, and the factors that consumers should consider when choosing the right tape for their needs.

Understanding PVC Electrical Tape

PVC (Polyvinyl Chloride) electrical tape is designed specifically for insulating and protecting electrical wires and connections. It is made from a flexible and durable plastic material that can withstand various environmental conditions, making it ideal for both indoor and outdoor use. The tape is characterized by its excellent adhesive properties, ability to resist moisture, and flexibility, which allows it to be applied to irregular surfaces.

Manufacturing Process

The production of PVC electrical tape involves several critical steps. The first stage is the formulation of the PVC resin, which is combined with additives to enhance its properties, such as flexibility, UV resistance, and flame retardancy. Once the formulation is complete, the mixture is extruded into thin sheets.

Next, these sheets are coated with a layer of adhesive on one side, which is crucial for ensuring a strong bond when the tape is applied. The coated sheets are then cut into various widths and lengths, depending on customer specifications. Quality control is a significant part of the manufacturing process, with rigorous testing conducted to ensure that the tape meets industry standards for electrical insulation and safety.

Leading manufacturers often invest in advanced technology and equipment to streamline production and maximize efficiency. Automation in the manufacturing process not only boosts productivity but also enhances the consistency and quality of the final product.

Factors to Consider When Choosing PVC Electrical Tape

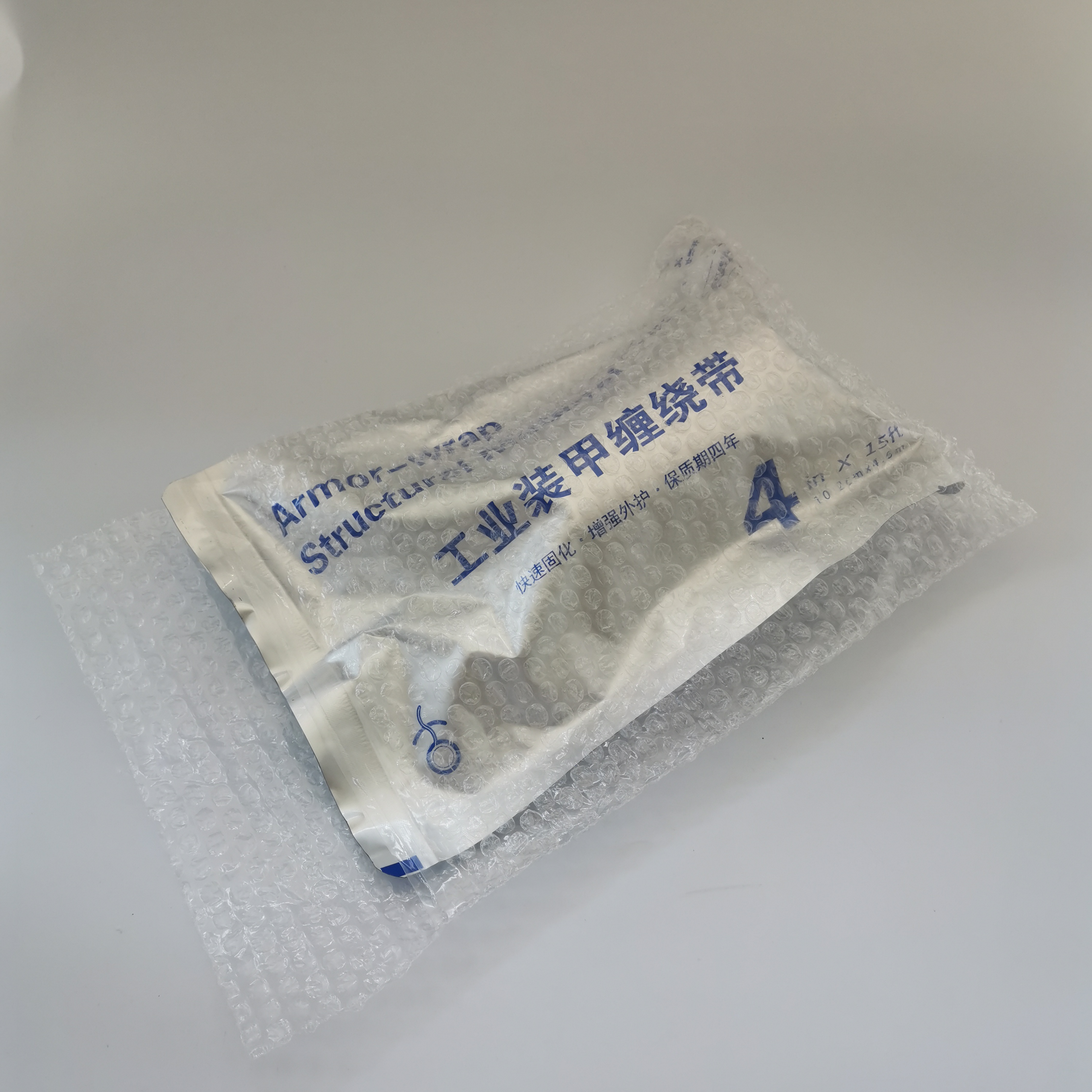

pvc electrical tape manufacturers

When selecting PVC electrical tape, consumers should consider several factors to ensure they choose the right product for their needs

1. Thickness and Width Different applications may require varying thicknesses and widths of tape. For instance, thicker tape may be suitable for high-voltage applications, while thinner tape can be ideal for general household wiring.

2. Adhesive Strength The effectiveness of the adhesive is crucial for the tape's performance. A strong adhesive ensures that the tape will stay in place, preventing electrical issues caused by loose connections.

3. Temperature Resistance Different PVC tapes are rated for specific temperature ranges. If the application involves exposure to high temperatures, it's essential to choose a tape that can withstand these conditions without degrading.

4. Color Coding PVC electrical tape is available in various colors, allowing for easy identification of electrical wires and circuits. This is particularly useful in complex installations where multiple wires are present.

5. Regulatory Compliance Ensure that the tape meets relevant industry standards and regulations for safety and performance. Reputable manufacturers will provide this information.

Conclusion

PVC electrical tape manufacturers play a crucial role in the electrical industry and DIY projects, providing essential products that ensure safety and efficiency. As consumers become more aware of the importance of quality in electrical components, manufacturers must continuously innovate and improve their production processes to meet these demands. By understanding the features and specifications of PVC electrical tape, consumers can make informed choices, ensuring reliable and safe electrical connections in all applications. The future of PVC electrical tape production looks bright, with ongoing advancements in materials and manufacturing technology set to enhance the performance and versatility of this essential product.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025