The Importance of Blue Tape in Electrical Work

Blue tape, often referred to as painter's tape or masking tape, plays a critical role in various applications, including electrical work. Though it may seem like a simple tool, blue tape offers numerous advantages that enhance safety, efficiency, and organization on the job. In this article, we will explore the different uses of blue tape in electrical tasks, its benefits, and best practices for effective use.

Uses of Blue Tape in Electrical Work

1. Marking Electrical Components One of the primary uses of blue tape in electrical work is to label and mark various components. When working on circuits, electricians often need to identify wires, switches, and circuit breakers clearly. Blue tape can be easily written on to denote specific functions, voltage levels, or intended connections, making the workspace more organized and reducing the likelihood of errors.

2. Protecting Surfaces Blue tape is a valuable tool for protecting surfaces during installation or repair work. Electricians often work in areas that require precision and cleanliness. By using blue tape to cover vulnerable surfaces, such as walls, fixtures, or floors, they can prevent scratches, paint splatters, or other damage that may occur during the job.

3. Temporary Hold During electrical installations or repairs, electricians may need to hold wires and components temporarily in place. Blue tape can be used to secure wires, junction boxes, or fixtures while ensuring that they are aligned correctly before final attachment. This allows for adjustments and helps maintain an orderly work environment.

4. Visibility in Low-Light Conditions Electrical work often takes place in poorly lit areas, such as basements or crawlspaces. The bright blue color of the tape provides an easy-to-see contrast against dark backgrounds, making it useful for marking important locations and ensuring that tools or materials are not accidentally left behind.

Benefits of Using Blue Tape

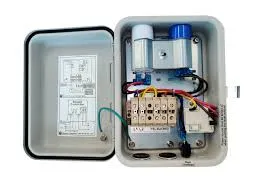

blue tape electrical

1. Easy Removal One of the standout features of blue tape is its ease of removal. Unlike traditional duct tape or other adhesives, which can leave sticky residues or damage surfaces, blue tape is designed to peel away cleanly without causing harm, making it ideal for temporary applications in electrical work.

2. Gentle Adhesion The adhesive on blue tape is specifically designed to hold firmly but not too aggressively, which means it can be used on a variety of surfaces without risking damage. This is particularly important when working with delicate materials or finishes.

3. Versatility Blue tape can be utilized for a wide range of tasks beyond electrical work. Its ability to conform to different surfaces makes it a versatile tool for any project that requires precision and protection. Electricians often find themselves turning to blue tape for a variety of applications, from marking to securing materials.

Best Practices for Using Blue Tape

1. Clean Surface For optimal adhesion, it’s important to apply blue tape to a clean surface. Dirt, dust, or grease can reduce the tape’s effectiveness.

2. Use the Right Width Blue tape comes in various widths. Choose a size that is appropriate for the task at hand. Wider tapes are excellent for covering larger areas, while narrower tapes are better suited for intricate markings.

3. Label Clearly When using blue tape for labeling, make sure to write clearly and avoid using abbreviations that may be confusing later. This will help ensure that all team members understand the markings.

In conclusion, blue tape is a simple yet invaluable tool in the realm of electrical work. Its versatility, ease of use, and ability to provide clear markings and protection make it an essential item in any electrician's toolkit. The next time you find yourself engaged in an electrical project, consider the many ways blue tape can enhance your efficiency and safety on the job.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025