The Versatile Applications of Self-Amalgamating Tape

Self-amalgamating tape, also known as self-fusing tape, is a unique type of adhesive tape that doesn't rely on any sticky backing to adhere to surfaces. Instead, it bonds to itself upon contact, creating a strong, waterproof seal. This remarkable property makes it an invaluable tool in various fields, from electrical work to plumbing and even emergency repairs. In this article, we'll delve into the diverse uses of self-amalgamating tape, highlighting its benefits and practical applications.

Electrical Applications

One of the most common uses of self-amalgamating tape is in the electrical industry. Electricians often utilize this tape to insulate exposed wires and repair damaged cables. Since it is made of rubber or silicone, it offers excellent resistance to moisture and temperature variations. When wrapped around wires, the tape fuses upon contact, creating a seamless and shockproof layer that enhances safety and reliability. This property is particularly beneficial in high-voltage environments, where electrical insulation is critical.

Moreover, self-amalgamating tape is often employed in the splicing of electrical cables. When connecting two wires together, electricians can wrap the joint in this tape to form an airtight seal, preventing water intrusion and corrosion, which can lead to electrical failures over time. Its ability to withstand a wide temperature range also means it can be used in various climates without losing effectiveness.

Plumbing Repairs

In the plumbing sector, self-amalgamating tape serves as an essential tool for emergency repairs. It can be used to seal leaks in pipes, fittings, and hoses. When water is pouring out of a pipe, quickly wrapping it with self-amalgamating tape can provide a temporary fix, allowing time for more permanent repairs or replacements. The tape forms a strong bond that resists water pressure and prevents further leakage, making it an ideal solution for urgent situations.

Additionally, when used on threaded connections, the tape can act as a waterproof gasket. This ensures that installed plumbing fixtures do not leak, providing peace of mind to homeowners and plumbers alike.

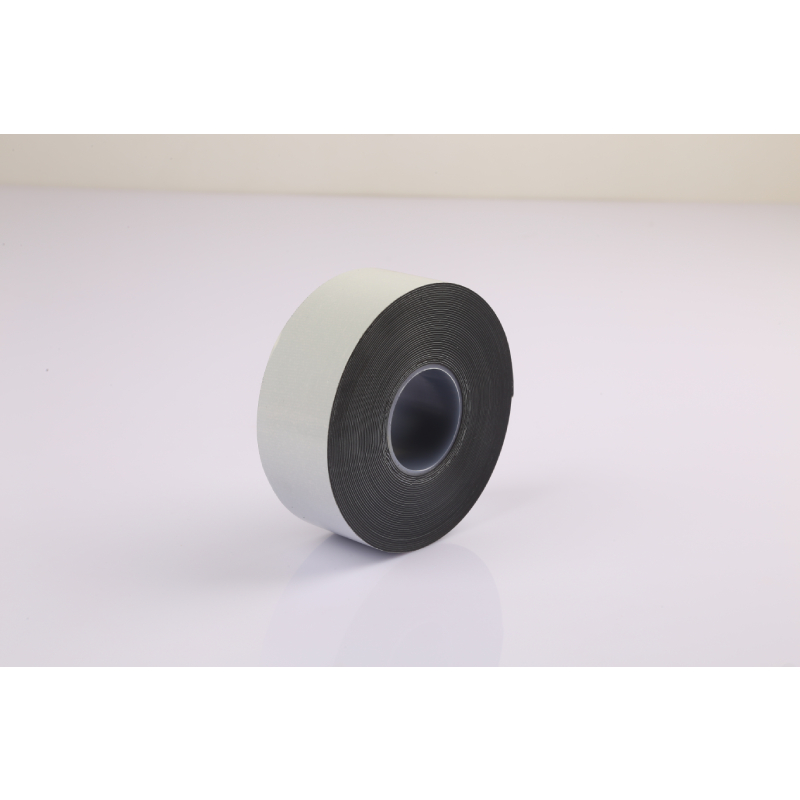

self amalgamating tape uses

Automotive and Marine Uses

Self-amalgamating tape also finds extensive use in the automotive and marine industries. Car enthusiasts might use it to wrap around wiring harnesses, protecting them from moisture and abrasion. Likewise, it can be applied to hoses and joints in vehicles to prevent fluid leaks. Its heat resistance and flexibility are particularly advantageous in these applications, where exposure to extreme conditions is common.

In marine environments, the tape can be used on boats and other watercraft to repair damaged wiring or create seals around various components, ensuring that everything remains watertight even in harsh conditions.

Outdoor Applications

Outdoor enthusiasts appreciate self-amalgamating tape for its versatility in various applications. It can be used to repair camping gear, hiking equipment, or even sports gear, providing a quick and reliable solution to tears, leaks, or other damage. For example, if a tent or sleeping bag develops a tear, a few wraps of self-amalgamating tape can quickly restore its functionality.

Additionally, it can serve as a temporary fix for sports equipment like racquets and poles, ensuring that adventurers can stay active without interruption.

Conclusion

Self-amalgamating tape is a versatile and practical tool that proves invaluable across many industries and applications. Whether in electrical repairs, plumbing, automotive maintenance, or outdoor activities, its unique properties allow it to create strong, durable seals without the mess of traditional adhesives. Its ability to insulate, protect, and provide quick fixes makes it a must-have item for both professionals and DIY enthusiasts alike. As technology continues to advance, the applications for self-amalgamating tape are likely to expand even further, solidifying its place as an essential repair solution.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025