The Versatility and Importance of Wide Electrical Tape

Wide electrical tape, often overlooked, plays a crucial role in both professional electrical work and everyday DIY projects. This seemingly simple tool is indispensable for a variety of applications, ranging from insulation to color coding wires. Its wide format and strong adhesive properties make it unique and extraordinarily useful in numerous contexts.

Applications of Wide Electrical Tape

One of the primary uses of wide electrical tape is insulation. It is designed to resist moisture, corrosion, and abrasion, making it an ideal choice for protecting electrical connections. When properly applied, wide electrical tape helps to prevent electrical shorts and protects against environmental factors that could degrade the quality of electrical systems. The width of the tape ensures that it covers larger areas, providing an increased barrier against potential hazards.

In commercial and industrial settings, wide electrical tape is frequently used for bundling wires and cables. When working on large installations, managing multiple cables can become chaotic. Wide electrical tape allows electricians and technicians to organize cables neatly, reducing clutter and improving safety. This organizational aspect is crucial in preventing accidents that may arise from tangled or exposed wires.

Another significant application of wide electrical tape is color coding. Different colors can represent different functions or voltages, which can be incredibly helpful when managing multiple circuits or cables. This instant visual identification can save valuable time during installation, maintenance, or troubleshooting. For instance, using red tape for high-voltage cables and blue for low-voltage ones can prevent errors and enhance safety.

Benefits of Using Wide Electrical Tape

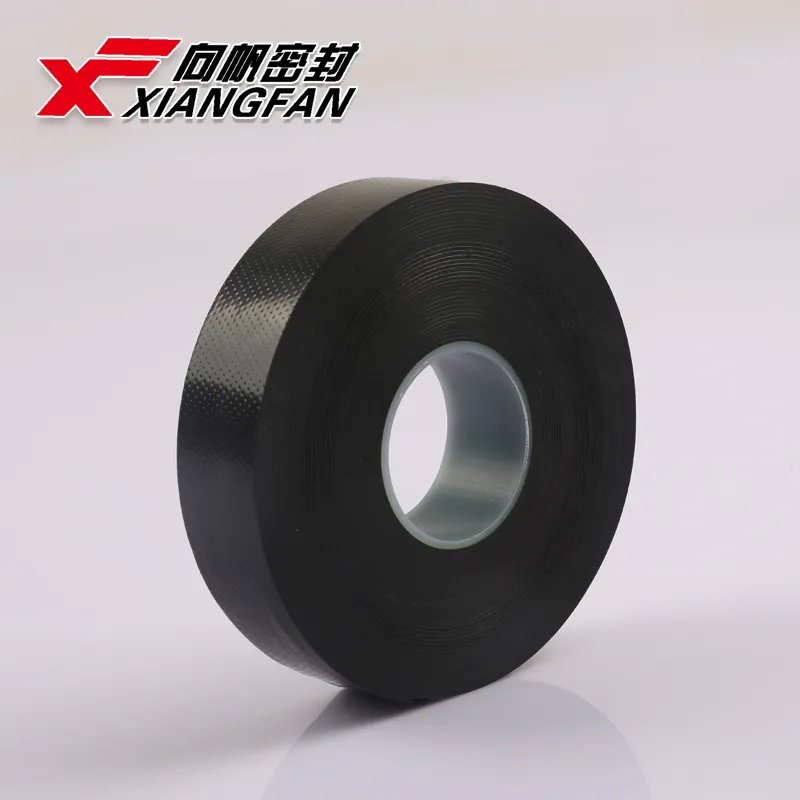

wide electrical tape

One of the key benefits of wide electrical tape is its durability. Made from high-quality materials, it can withstand extreme temperatures and harsh environmental conditions. This resilience makes it suitable for both indoor and outdoor applications. Whether in a residential setting or a rugged industrial environment, wide electrical tape effectively performs its job without losing its adhesive properties.

Moreover, the ease of application is another advantage. Unlike heat-shrink tubing, which requires special tools to apply, electrical tape can be used by anyone. It can be torn by hand and does not require any additional equipment, making it a convenient choice for electricians and DIY enthusiasts alike. This simplicity encourages more people to engage in safe electrical practices, leading to better overall safety standards in various projects.

Safety Considerations

While wide electrical tape is a versatile and essential tool, improper usage can lead to risks. It is crucial to ensure that the tape is applied correctly, covering all exposed areas while avoiding overlap that could create thickness and potential overheating. Additionally, it is important to use electrical tape specifically designed for electrical applications. General-purpose tapes may not provide the same level of insulation or heat resistance.

Conclusion

In conclusion, wide electrical tape is more than just a tool; it is an essential component in ensuring safety, organization, and efficiency in electrical work. Its versatile applications and benefits make it a staple in both professional and home improvement settings. As the world becomes increasingly electrified, the importance of reliable tools like wide electrical tape cannot be underestimated. Whether it’s for insulation, bundling, or color coding, this simple tool remains a critical element in maintaining electrical systems safely and effectively. As such, having a roll of wide electrical tape on hand is wise for anyone dealing with wiring, whether it be in a professional capacity or as a dedicated DIYer.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025