The Versatility of Vulcanising Tape A Comprehensive Guide

Vulcanising tape, often referred to as self-fusing or silicone tape, is a remarkable product that has won favor across various industries due to its unique properties and versatile applications. Initially developed for electrical insulation, this tape has expanded its use into plumbing, automotive, and even household repairs. In this article, we will explore the key features, benefits, and applications of vulcanising tape, along with some tips for effective usage.

What is Vulcanising Tape?

Vulcanising tape is a type of rubber tape that self-bonds upon contact with itself, creating a waterproof, airtight seal. This special feature makes it differ from traditional adhesive tapes that require a sticky surface to adhere. Often made from silicone or other elastomeric materials, vulcanising tape can withstand high temperatures and resist chemicals, making it ideal for challenging environments.

Key Features

1. Self-Fusing The primary characteristic of vulcanising tape is its ability to bond with itself without using any adhesives. This self-fusing property allows for seamless applications without a messy residue.

2. Temperature Resistance Vulcanising tape can typically withstand temperatures ranging from -50°C to 260°C (-58°F to 500°F). This makes it suitable for both hot and cold environments, particularly in automotive and industrial applications.

3. Waterproof and Insulating When properly applied, vulcanising tape forms a waterproof seal, making it excellent for plumbing repairs and electrical insulation. It prevents moisture ingress, ensuring safety and longevity in repairs.

4. Chemical Resistance The tape is resistant to various chemicals, oils, and solvents, making it suitable for use in harsh industrial settings or around vehicles.

Applications

- Electrical Insulation Vulcanising tape is widely used in electrical work to insulate wires and cables. Its high dielectric strength ensures safety in electrical installations.

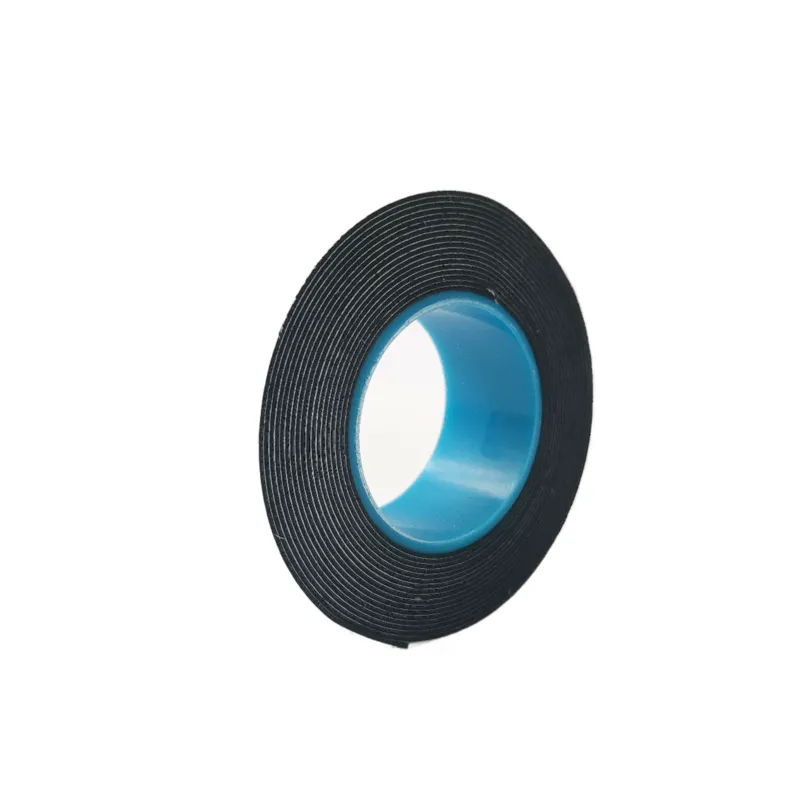

vulcanising tape

- Plumbing Repairs For quick fixes in plumbing, vulcanising tape can seal leaks in hoses, pipes, and connectors. Its waterproof properties guarantee that the repair holds under pressure.

- Automotive Use Mechanics often use vulcanising tape to repair hoses, cables, and connectors. Its ability to tolerate extreme temperatures makes it ideal for engine compartments.

- Household Repairs Beyond industrial applications, vulcanising tape is an excellent tool for general household repairs. It can fix garden hoses, hold together equipment, or provide a temporary patch for various items.

Tips for Effective Use

1. Clean the Surface Before applying vulcanising tape, ensure that the surface is clean and dry. Dirt, oil, or moisture can inhibit the tape’s ability to bond effectively.

2. Stretch While Applying To maximize the seal's strength, stretch the tape slightly as you wrap it around the surface. This elongation helps create a tighter bond.

3. Overlap Layers When wrapping, overlap each layer by about half to ensure comprehensive coverage and a robust seal.

4. Allow Time to Fuse After applying the tape, give it some time to bond properly, especially in areas exposed to heat or pressure.

Conclusion

Vulcanising tape is an essential tool in many fields, offering an efficient and reliable solution for a multitude of challenges. Its self-fusing capabilities, combined with waterproofing and chemical resistance, make it a favorite among professionals and DIY enthusiasts alike. Whether repairing electrical wiring, plumbing issues, or general household items, vulcanising tape proves its reliability time and again. Its versatility not only saves time but also ensures that repairs are durable and effective. As such, this unassuming yet powerful tape deserves a place in every toolbox.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025