The Importance of Waterproof Rubber Sealing Strips

Waterproof rubber sealing strips play a crucial role in various applications, from automotive and construction to electronics and household items. These strips, designed to provide airtight and watertight seals, are essential in ensuring the durability and functionality of products by preventing water, dust, and other contaminants from entering sensitive areas.

One of the primary uses of waterproof rubber sealing strips is in vehicles. They are strategically placed around doors, windows, and trunks to prevent water leaks and protect the interior from moisture damage. A well-sealed vehicle not only enhances safety but also improves energy efficiency by minimizing the need for heating or cooling, which is particularly important in extreme weather conditions.

In the construction industry, waterproof rubber sealing strips are commonly used in doors and windows to ensure that buildings remain energy-efficient and dry. They help to keep out rainwater and wind, thus maintaining a comfortable indoor environment. Additionally, these seals are vital for preventing mold growth and structural damage caused by water intrusion, which can lead to costly repairs over time.

waterproof rubber sealing strip

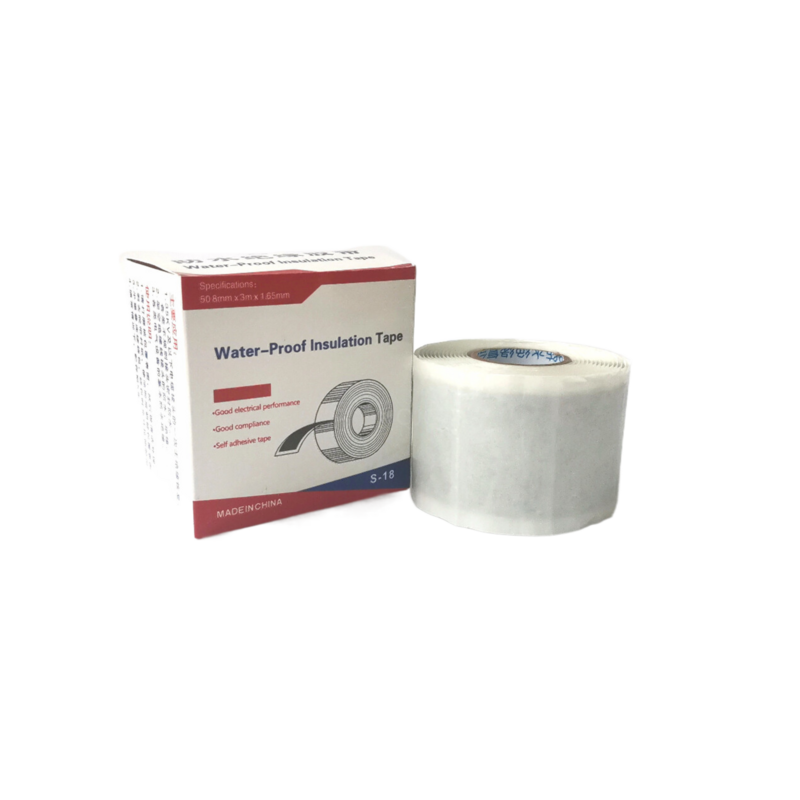

Electronics also benefit greatly from waterproof rubber sealing strips

. Many electronic devices, especially those used outdoors or in harsh environments, require protection from moisture and dust. Sealing strips are utilized in items such as smartphones, outdoor cameras, and industrial equipment to prevent moisture damage, ensuring that these devices remain operational and reliable, even in adverse conditions.Household applications of waterproof rubber sealing strips include bathtubs, showers, and sinks. They are used to create watertight seals that prevent leaks and water damage, protecting the home's structure and reducing the risk of expensive repairs. Furthermore, these sealing strips can help improve the overall aesthetic of a space by providing a clean and polished finish around fixtures.

Choosing the right type of waterproof rubber sealing strip is essential. Factors such as the material, thickness, and adhesive strength can significantly impact the effectiveness of the seal. Common materials for waterproof sealing strips include silicone, EPDM (ethylene propylene diene monomer), and neoprene, each offering different levels of resistance to temperature, chemicals, and UV exposure.

In conclusion, waterproof rubber sealing strips are integral to a wide range of applications, ensuring protection against water, dust, and other contaminants. Their ability to create airtight and watertight seals enhances the safety, efficiency, and longevity of products, making them an essential component in many industries. Whether in vehicles, buildings, electronics, or everyday household items, these sealing strips are indispensable for maintaining performance and preventing damage.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025