The Importance of Waterproof Rubber Sealing Strips

In an era where the integrity and longevity of products are paramount, waterproof rubber sealing strips have emerged as essential components in various industries. These strips serve multifunctional purposes that significantly enhance the durability and reliability of countless applications, ranging from construction to automotive, and from household appliances to electronic devices. Understanding their composition, functionality, and applications can help appreciate why they are a necessary investment for both manufacturers and end-users.

What are Waterproof Rubber Sealing Strips?

Waterproof rubber sealing strips are flexible, durable barriers made from synthetic or natural rubber, designed to prevent the ingress of water and other environmental elements. These strips are often used alongside doors, windows, enclosures, and machinery where sealing is required. Their primary feature—water resistance—ensures that areas remain secure from potential moisture damage. Besides their waterproof characteristics, these sealing strips can also provide thermal insulation, noise reduction, and protection against dust and debris.

Composition and Features

The composition of waterproof rubber sealing strips typically involves high-quality elastomers, which provide resilience and flexibility. Common materials include neoprene, EPDM (ethylene propylene diene monomer), and silicone. Each of these materials offers unique properties, making them suitable for different applications.

1. Neoprene Known for its excellent resistance to water and weathering, neoprene sealing strips are ideal for outdoor applications. Their flexibility enables a snug fit in most sealing environments, making them useful in automotive and marine industries.

2. EPDM This type of rubber is particularly noted for its exceptional weather resistance and UV stability, making it perfect for architectural applications. EPDM sealing strips maintain their shape and integrity over time, even when exposed to extreme temperatures.

3. Silicone Silicone sealing strips offer high elasticity and a broader temperature tolerance. They are frequently used in applications requiring consistent performance under thermal fluctuations, such as in kitchen appliances and HVAC systems.

Applications

Waterproof rubber sealing strips can be found in an array of applications, demonstrating their versatility and practicality

- Construction In the building industry, sealing strips are crucial for waterproofing. They are used around doors, windows, and roofs to ensure that water does not penetrate the structure, which can lead to costly damage and mold growth.

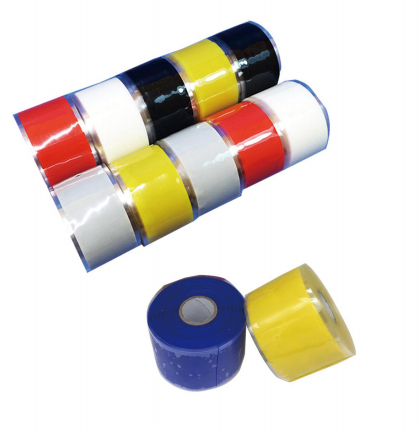

waterproof rubber sealing strip

- Automotive In vehicles, these strips are used to seal doors, hatches, and windows. Effective sealing prevents water ingress, ensuring passenger comfort and safety, and maintaining the integrity of electrical systems from moisture damage.

- Household Appliances Many household appliances utilize waterproof rubber sealing strips to enhance energy efficiency and prevent water leakage

. For example, washing machines and refrigerators rely on these seals to operate effectively.- Electronics In the electronics industry, waterproof sealing strips are vital for safeguarding sensitive components from water damage, enhancing the reliability of devices in various environments.

Benefits

The advantages of using waterproof rubber sealing strips are manifold

- Enhanced Durability These strips significantly prolong the life of products by preventing moisture-related damage, reducing maintenance costs and downtime.

- Energy Efficiency By effectively sealing gaps and preventing thermal exchange, sealing strips contribute to better energy efficiency in heating and cooling systems.

- Safety In automotive and electrical applications, waterproof sealing helps prevent potentially hazardous situations caused by moisture-related failures.

- Noise Reduction They provide an additional benefit of soundproofing, improving the comfort of indoor spaces.

Conclusion

In conclusion, waterproof rubber sealing strips are indispensable in modern manufacturing and construction. Their ability to provide effective barriers against water and other environmental factors enhances product longevity, efficiency, and safety. Companies across various sectors recognize the value of these seals not just as an added feature but as core components that uphold quality and performance. As technology advances and the demands for better and more efficient sealing solutions grow, the importance of waterproof rubber sealing strips will undoubtedly continue to rise, reflecting their indispensable role in ensuring reliability across numerous applications.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025