The Importance of Waterproof Rubber Strips in Modern Applications

In today's fast-paced world, where innovation meets necessity, materials that ensure longevity and reliability have become critical in various industries. Among these materials, waterproof rubber strips stand out due to their versatile applications and importance in maintaining the integrity of structures and products. Whether in construction, automotive, or manufacturing, waterproof rubber strips play a vital role in sealing joints, preventing leaks, and ensuring durability.

Understanding Waterproof Rubber Strips

Waterproof rubber strips are composed of synthetic rubber materials designed to repel water and resist degradation from environmental factors. These strips are manufactured through precise processes that enhance their elasticity, resilience, and resistance to extreme temperatures, making them suitable for numerous applications. Depending on their formulation, these rubber strips can be used in settings that experience varying degrees of exposure to water, chemicals, and wear.

Key Characteristics

One of the foremost features of waterproof rubber strips is their ability to create airtight seals

. This quality is paramount in applications such as doors and windows, where preventing water intrusion is essential for maintaining energy efficiency and protecting interiors from moisture damage. Furthermore, waterproof rubber strips are resistant to UV rays, ozone, and various chemicals, which prolongs their lifespan and ensures that they remain effective over time.Another significant characteristic is their flexibility. Waterproof rubber strips can be easily manipulated to fit various shapes and sizes, making them ideal for a multitude of applications. Their inherent elasticity allows them to conform to surfaces, ensuring a snug fit that minimizes gaps where water could infiltrate. Additionally, these strips are available in various thicknesses and widths, catering to specific needs across different industries.

Applications of Waterproof Rubber Strips

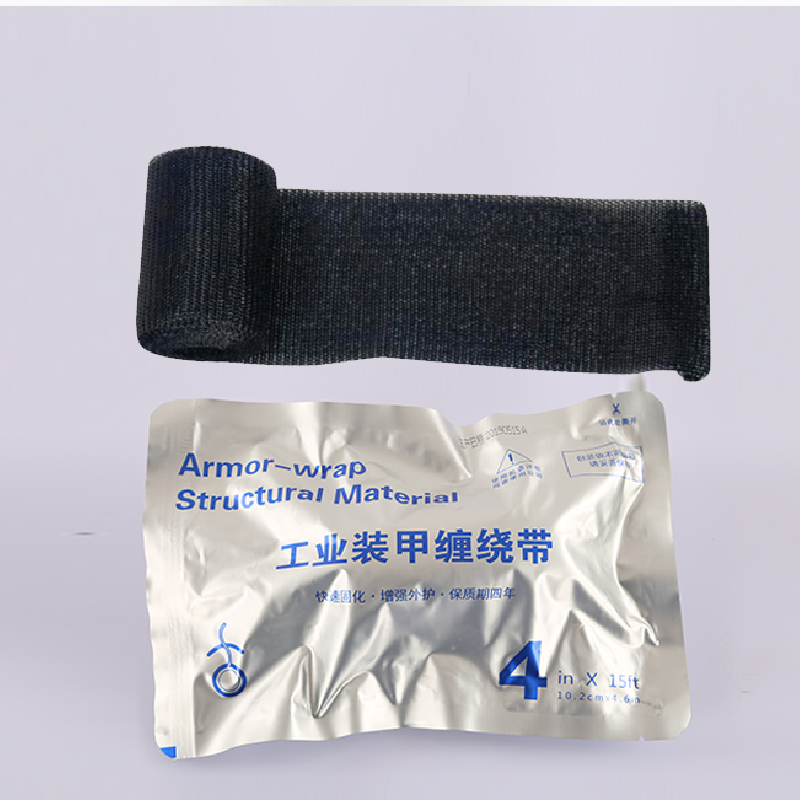

waterproof rubber strip

1. Construction and Architecture In the construction industry, waterproof rubber strips are extensively used in sealing windows, doors, and roofing systems. They are crucial in preventing water leakage, which can lead to significant structural damage if left unaddressed. The use of these strips helps in meeting building codes that require water resistance, ultimately protecting not just the structure but also its inhabitants.

2. Automotive Industry The automotive sector relies heavily on waterproof rubber strips to ensure vehicle integrity. These strips are used in door seals, windshields, and underbody applications. They prevent water from entering the vehicle, protecting internal components and improving passenger comfort by reducing noise and wind intrusion.

3. Electric Appliances Waterproof rubber strips are also vital in the manufacturing of electric appliances, particularly those used in wet environments such as kitchens and bathrooms. They serve as barriers to water, protecting sensitive electronic components from moisture, thus enhancing safety and longevity.

4. Marine Applications In marine environments, equipment and vessels are constantly exposed to water. Waterproof rubber strips are employed in boats, yachts, and other marine applications to seal hatches, windows, and joints, ensuring that water does not compromise the integrity of the vessel.

5. HVAC Systems These strips also play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They help seal ducts and components, preventing the leakage of conditioned air and ensuring that systems operate efficiently.

Conclusion

Waterproof rubber strips are an essential component in multiple industries, providing effective solutions for sealing and moisture protection. Their versatility, durability, and inherent resistance to water and environmental damage make them indispensable in construction, automotive, electrical, and marine applications. As industries evolve and demand for sustainable and reliable materials increases, waterproof rubber strips are likely to play an even more significant role in future innovations.

In summary, the reliable performance of waterproof rubber strips not only enhances the quality of products but also contributes to safety and comfort in various applications. By investing in high-quality waterproof rubber strips, manufacturers can ensure that their products withstand the test of time and function optimally under various conditions.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025