The Benefits and Applications of Self-Amalgamating Tape

In the world of adhesives and sealing solutions, self-amalgamating tape, also known as self-fusing or self-bonding tape, has emerged as a versatile and efficient product. Its unique properties make it ideal for a wide range of applications, from electrical insulation to plumbing repair, and its ease of use further enhances its appeal.

What is Self-Amalgamating Tape?

Self-amalgamating tape is made from a rubber-based material that does not contain an adhesive; instead, it fuses to itself when stretched and wrapped around an object. This tape typically consists of a silicone or EPDM (ethylene propylene diene monomer) rubber compound that offers excellent resistance to temperature fluctuations, moisture, and UV exposure. When applied, the tape creates a seamless, resilient barrier that is not only waterproof but also provides electrical insulation.

Key Features

1. Self-Fusing One of the most significant advantages of self-amalgamating tape is its self-fusing property. When wrapped under tension, the tape creates a strong bond with itself, ensuring a permanent seal without the need for adhesives.

2. Versatile Temperature Range Self-amalgamating tape can often withstand a wide range of temperatures, typically from -40°F to 250°F (-40°C to 121°C) or even higher, depending on the specific product. This makes it suitable for indoor and outdoor applications, as well as in harsh environmental conditions.

3. Electrical Insulation Because of its insulating properties, self-amalgamating tape is commonly used in electrical applications. It can effectively cover exposed wires, providing protection against moisture and preventing short circuits.

4. Waterproof The tape creates a waterproof seal, which is essential in plumbing repairs or outdoor applications, where exposure to water is a concern.

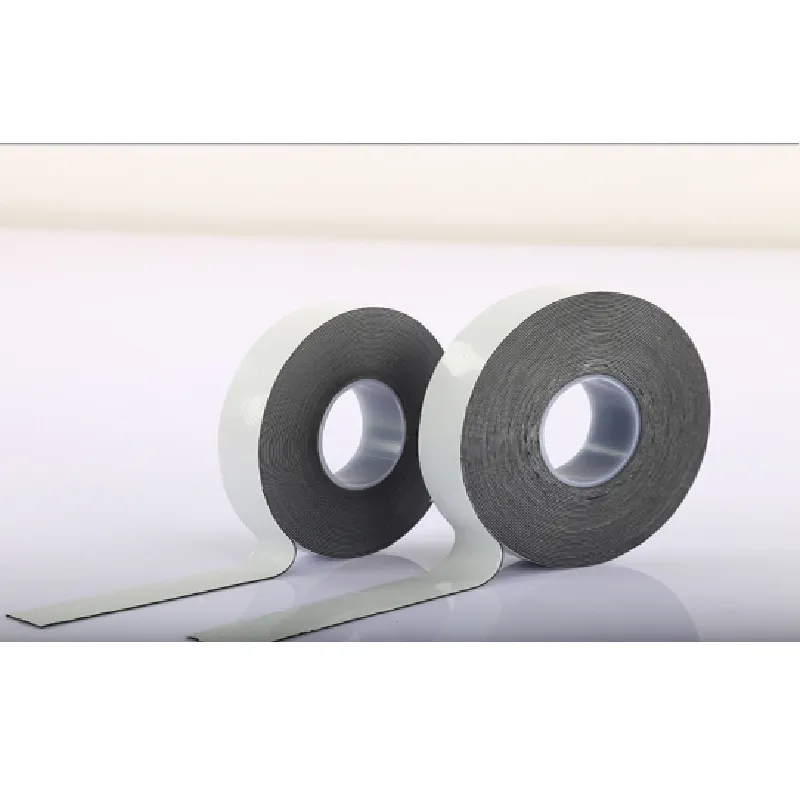

white self amalgamating tape

Applications

1. Electrical Repairs Self-amalgamating tape is a staple in both professional and DIY electrical repairs. It's particularly useful for insulating electrical splices and connections, where traditional electrical tape may fail over time.

2. Plumbing Repairs Leaky pipes can lead to significant damage if not promptly addressed. Self-amalgamating tape can be used to wrap around leaks or cracks temporarily until a more permanent solution is implemented.

3. Automotive Uses In automotive applications, self-amalgamating tape can be used to repair wiring harnesses, cover exposed battery terminals, and seal components from moisture damage.

4. Sporting Goods Athletes and outdoor enthusiasts may use this tape to insulate or protect their gear, such as wrapping grips on fishing rods or bicycles for improved handling and grip.

5. Home Improvement Homeowners can utilize self-amalgamating tape for various repair projects around the house, offering a quick solution for sealing or insulating needs.

Conclusion

Self-amalgamating tape is not just another adhesive solution; it is a remarkable product that has found its way into countless applications across various industries. From providing electrical insulation to serving as a quick fix for plumbing issues, its ability to bond with itself without adhesives makes it an indispensable tool for professionals and DIY enthusiasts alike. Its versatility, ease of use, and effectiveness in demanding environments solidify its place as a go-to solution for sealing and insulating, proving that sometimes simplicity in design leads to the most effective results. Whether you are tackling a home improvement project or dealing with a technical repair, self-amalgamating tape is a reliable choice that delivers lasting performance.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025