The Importance of Cloth Wiring Harness Tape in Modern Applications

In the world of electrical engineering and automotive design, the significance of effective wiring solutions cannot be overstated. Among various options available, cloth wiring harness tape stands out as a popular choice due to its unique properties and versatile applications.

What is Cloth Wiring Harness Tape?

Cloth wiring harness tape is a type of adhesive tape made from woven fabric material, often coated with a pressure-sensitive adhesive. This tape is designed to bundle and organize wires and cables in a variety of applications, especially in automotive wiring and electrical assemblies. Its texture and composition make it suitable for use in demanding environments where flexibility, durability, and heat resistance are essential.

Key Features of Cloth Wiring Harness Tape

1. Durability One of the key benefits of cloth wiring harness tape is its robustness. It can withstand a range of environmental factors, including temperature fluctuations, moisture, and mechanical abrasion. This durability makes it an ideal choice for wiring applications in vehicles, aerospace, and even industrial machinery.

2. Flexibility The fabric composition of the tape allows it to conform to various shapes and sizes of wire bundles. This flexibility facilitates neat and organized installations, preventing tangles and ensuring ease of access for maintenance and inspection.

3. Insulation Properties While cloth wiring harness tape is not primarily an insulating material, it does provide a certain degree of electrical insulation. This characteristic helps to protect wires from abrasion and damage, enhancing the overall integrity of the wiring system.

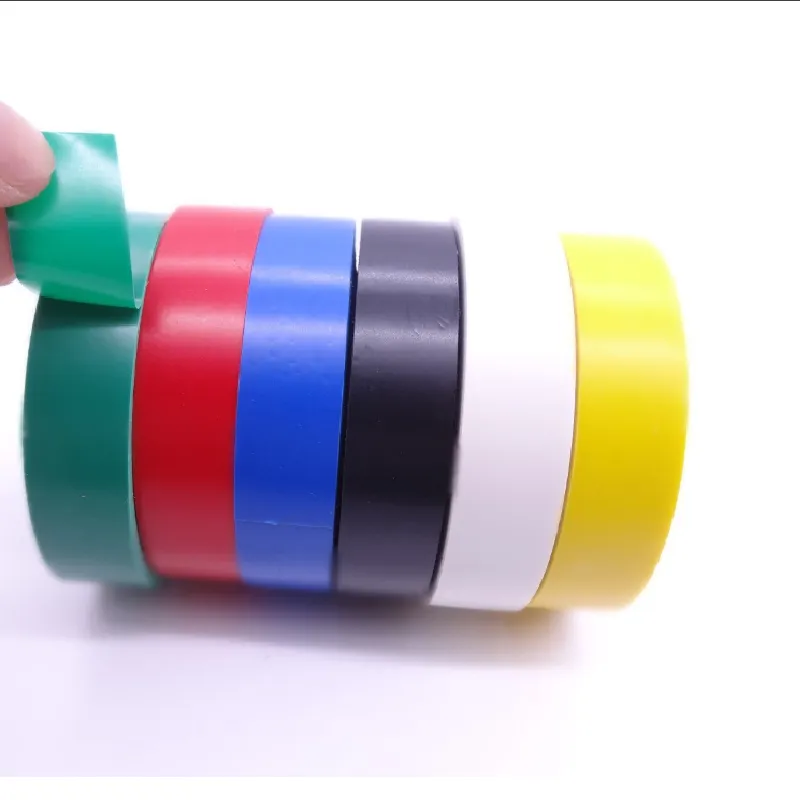

4. Aesthetic Appeal In addition to its functional advantages, cloth wiring harness tape is available in various colors and finishes. This aesthetic quality is increasingly being recognized in industries where visual appeal is critical, such as automotive interiors, allowing manufacturers to create visually pleasing and well-organized wiring systems.

cloth wiring harness tape

5. Ease of Application The tape is user-friendly and can be easily hand-applied or machine-applied, depending on the requirements of the production process. This ease of use simplifies the assembly process for manufacturers, improving efficiency and productivity.

Applications of Cloth Wiring Harness Tape

The versatility of cloth wiring harness tape allows it to be utilized in a broad range of applications

- Automotive Industry In the automotive sector, cloth wiring harness tape is extensively used to secure wiring harnesses within vehicles. It helps to maintain order among the many wires and cables, preventing wear and ensuring longevity.

- Aerospace In aerospace applications, where safety and reliability are paramount, cloth wiring harness tape is employed to bundle wires in aircraft. Its resistance to extreme temperatures and conditions makes it suitable for use in this demanding industry.

- Consumer Electronics Many electronic devices, from computers to household appliances, use cloth wiring harness tape to manage internal wiring. Its insulative properties and aesthetic appeal help to create more reliable and visually pleasing products.

- Industrial Equipment Cloth wiring harness tape is also used in industrial applications, securing cables in manufacturing equipment and machinery. Its durability ensures that it can withstand the rigors of heavy-duty usage.

Conclusion

In summary, cloth wiring harness tape is an essential component in today's wiring solutions across multiple industries. Its durability, flexibility, insulative properties, and aesthetic qualities make it a preferred choice for bundling and organizing wires and cables. As technology continues to advance, the demand for efficient, reliable, and visually appealing wiring solutions will only grow, further solidifying the role of cloth wiring harness tape as a critical element in electrical and automotive design. Whether in cars, planes, or electronic devices, this tape plays a vital role in ensuring safe, reliable, and efficient operation.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025