Understanding High Temperature Electrical Tape Applications and Importance

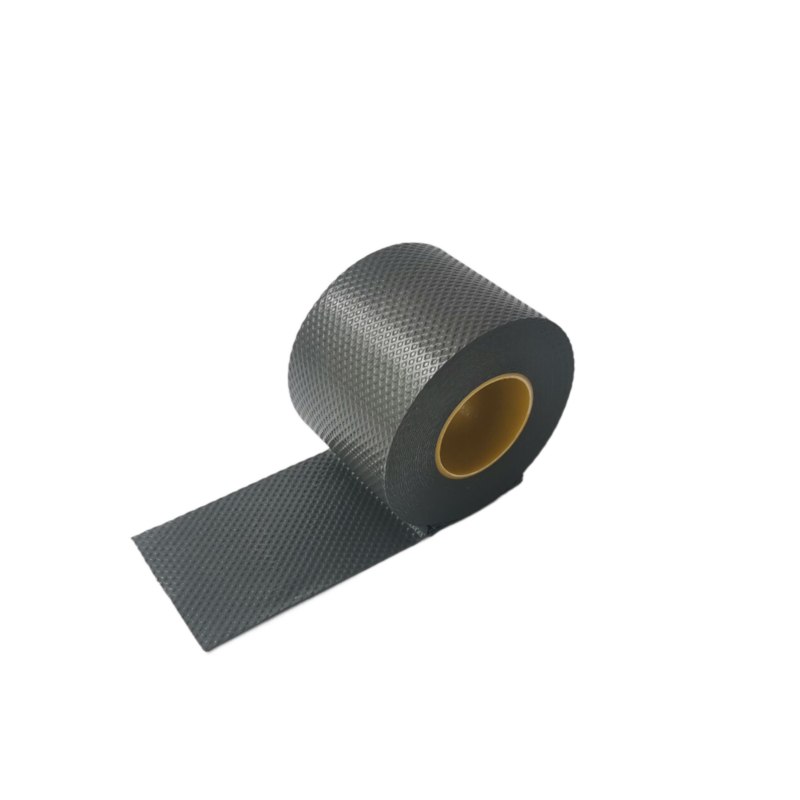

High temperature electrical tape is an essential material in various industries, particularly in electrical and electronic applications. This specialized tape is designed to withstand extreme temperatures, making it invaluable for insulation, protection, and securing components in high-temperature environments.

What is High Temperature Electrical Tape?

High temperature electrical tape is typically made from materials such as silicone or polyimide, which can endure heat levels beyond those acceptable for standard electrical tapes. These materials are engineered to maintain their integrity and adhesion properties when exposed to high temperatures, ensuring reliable performance in demanding conditions. Most high temperature tapes can operate effectively at temperatures ranging from 100°C (212°F) to 260°C (500°F), making them suitable for various applications, from automotive to aerospace industries.

Applications of High Temperature Electrical Tape

One of the primary uses of high temperature electrical tape is in electrical insulation for wiring and circuitry. In environments where components can heat up significantly, traditional insulation materials may fail, leading to shorts, degradation, or even fires. High temperature tape provides a protective barrier, ensuring electrical safety and system reliability.

In the automotive sector, high temperature electrical tape is used for wrapping wiring harnesses and protecting sensitive electronic components from heat generated by engines and exhaust systems

. Additionally, it can also serve as a protective layer in various manufacturing processes where heat is a concern, such as motor and generator manufacturing.high temperature electrical tape

In aerospace applications, high temperature electrical tape plays a crucial role in securing wiring and insulating components in aircraft. Due to the extreme conditions these vehicles encounter, the ability of high temperature tape to maintain performance under heat is critical to safety and operational efficiency.

Benefits of High Temperature Electrical Tape

The benefits of using high temperature electrical tape extend beyond its heat resistance. The tape offers excellent dielectric strength, which is crucial for preventing electrical failures. Its flexibility allows it to conform easily to various shapes and surfaces, making it easier to apply and ensuring a snug fit around components.

Moreover, high temperature electrical tape is resistant to chemicals, moisture, and UV light, increasing its durability and lifespan. This resistance to environmental factors ensures that the tape remains effective over time, even in challenging conditions.

Conclusion

In conclusion, high temperature electrical tape is a pivotal component in many industrial and commercial applications. Its ability to withstand extreme temperatures while providing reliable insulation and protection makes it a preferred choice for engineers and technicians. As industries continue to push the boundaries of technology and materials, the importance of high temperature electrical tape will only grow, ensuring safety and performance in ever-evolving environments. Whether in automotive, aerospace, or electrical engineering, high temperature electrical tape is a small yet crucial element that contributes significantly to the functionality and safety of complex systems.

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025