The Versatility and Benefits of 130c% Rubber Tape

In the world of adhesives and sealing materials, 130c% rubber tape stands out as a versatile and reliable option for a variety of applications. This specially formulated tape combines the elastic properties of rubber with the strong adhesion characteristics, making it suitable for different environments and uses. Whether in industrial settings, construction sites, or DIY home projects, 130c% rubber tape is an essential tool that offers numerous benefits.

What is 130c% Rubber Tape?

130c% rubber tape is made from a high-performance rubber compound that allows for exceptional elasticity and flexibility. The designation 130c% refers to the tape's capability to stretch up to 130% of its original length without losing its integrity. This feature is especially useful in applications where movement and expansion occur, ensuring that the tape can accommodate changes without breaking or losing its adhesive properties.

The outer surface of the tape is typically coated with a sticky adhesive that provides a strong bond to various surfaces, including metals, plastics, and glass. This adhesive is designed to withstand various environmental factors, including moisture, heat, and chemicals. As a result, 130c% rubber tape is employed in a range of settings, from automotive repairs to plumbing applications.

Applications of 130c% Rubber Tape

One of the significant advantages of 130c% rubber tape is its versatility

. Here are some of the most common applications1. Electrical Insulation Given its excellent dielectric properties, the tape is often used in electrical applications to insulate wires and prevent short circuits. It effectively protects electrical components from moisture and dust, minimizing the risk of damage.

2. Plumbing Repairs The tape's waterproof characteristics make it ideal for sealing leaks in pipes and fittings. It can be applied to metal, PVC, and other pipe materials, providing a robust and lasting seal that resists water ingress.

3. Automotive Uses Mechanics frequently use 130c% rubber tape for various automotive repairs. It can seal hoses, protect wires, and serve as a temporary fix for leaks. Its heat-resistant properties make it suitable for high-temperature environments found in engines and exhaust systems.

4. General Repairs and Maintenance Many homeowners and DIY enthusiasts keep rubber tape on hand for general repairs. Its ability to conform to various shapes and surfaces allows for quick fixes in a wide array of household items, from repairing the handle of a tool to sealing a cracked garden hose.

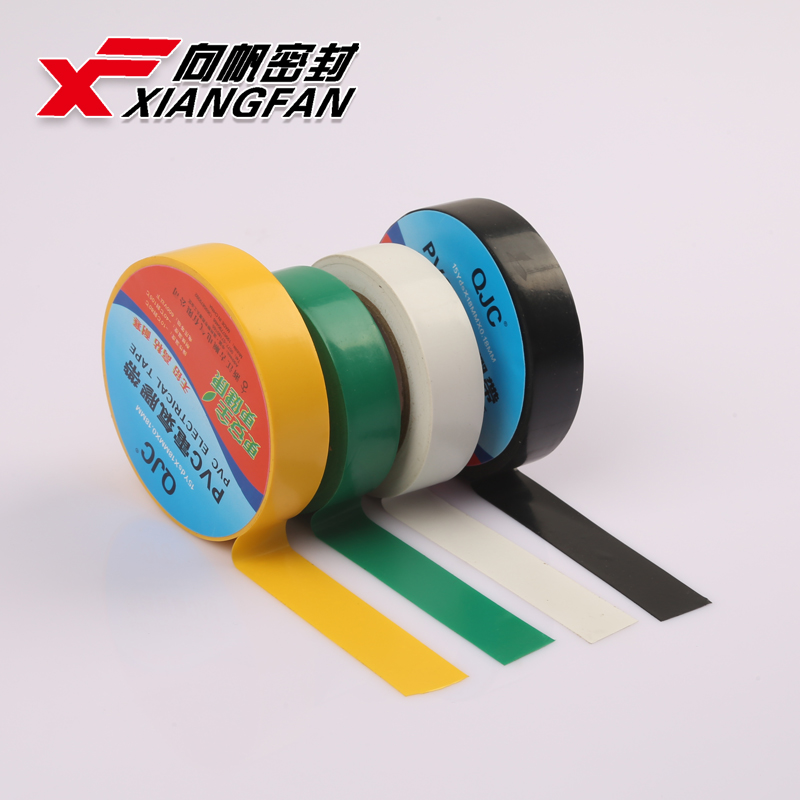

130c rubber tape

5. Construction Applications In the construction industry, 130c% rubber tape is commonly utilized for waterproofing and sealing joints between building materials. Its durability ensures that it can withstand the rigors of construction sites and harsh weather conditions.

Advantages of Using 130c% Rubber Tape

The use of 130c% rubber tape offers numerous advantages

- Durability The robust nature of the rubber material ensures that the tape can withstand wear and tear, making it a long-lasting option for various applications.

- Ease of Use The self-adhesive backing makes it easy to apply—no need for additional tools or adhesives.

- Flexibility Its ability to stretch allows it to conform perfectly to the surface it's applied to, providing an effective seal even on uneven surfaces.

- Chemical Resistance The tape is resistant to many chemicals, including solvents and oils, making it suitable for industrial environments.

- Temperature Resilience 130c% rubber tape can perform well across a wide temperature range, maintaining its adhesive properties in both hot and cold conditions.

Conclusion

In summary, 130c% rubber tape is a highly versatile and effective solution for an array of sealing and insulation needs. With its unique properties and various applications, it is a valuable addition to both industrial and home repair toolkits. Whether you are an electrician, plumber, mechanic, or a DIY homeowner, integrating 130c% rubber tape into your projects can enhance efficiency and effectiveness. Its ability to withstand various environmental challenges while providing strong adhesion makes it an indispensable tool for anyone involved in repair, maintenance, or construction.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025