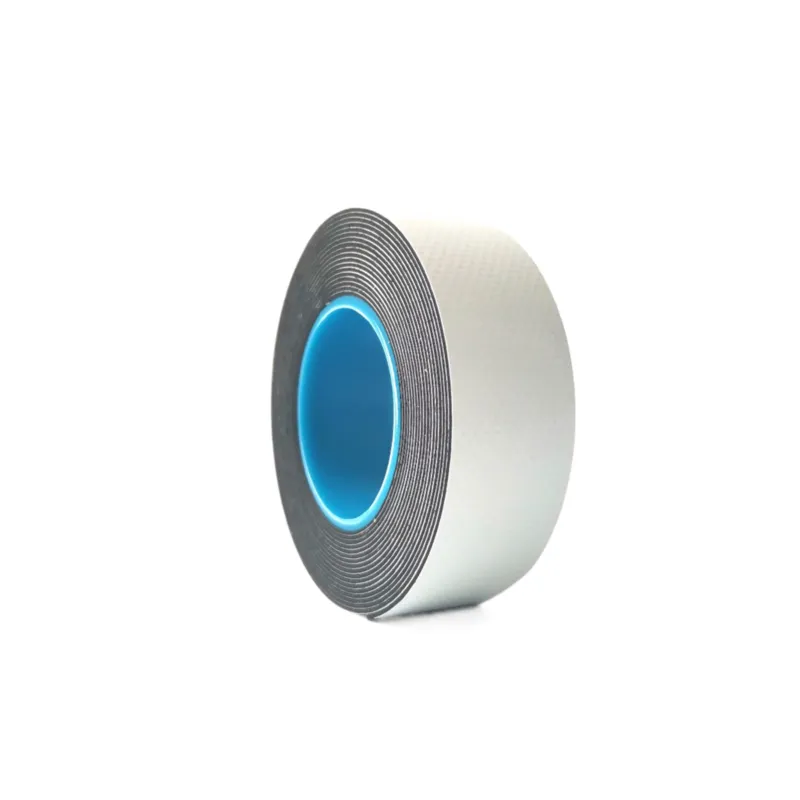

high heat electrical tape

Back to list

ਜਨਃ . 29, 2025 01:50

In the realm of electrical work, where precision and safety are paramount, the choice of materials can make a significant difference. Among these materials, high heat electrical tape plays a crucial role, especially in environments characterized by elevated temperatures and potential exposure to high-voltage circuits. Designed to withstand extreme conditions, this specialized tape not only ensures safety but also enhances the longevity of electrical systems.

Moreover, manufacturer grades often specify the temperature range a particular high heat electrical tape can endure, alongside additional characteristics like tensile strength and elongation. Expertise in this domain guides electricians in selecting the right type of tape, ensuring the safety and efficiency of complex electrical systems. The authority of high heat electrical tape is backed by stringent testing and compliance with industry standards. Reputable manufacturers conduct rigorous assessments, ensuring their products meet or exceed safety regulations. This includes tests for flame retardancy, thermal conductivity, and chemical resistance. Such validation not only assures users of the tape’s performance under extreme conditions but also underscores the manufacturer’s commitment to quality. Given the critical applications of electrical tapes, authoritative endorsements provide users with peace of mind, knowing their safety measures are failproof. Trustworthiness in high heat electrical tape hinges on transparent communication from manufacturers regarding the tape’s capabilities and limitations. Labels specifying the temperature ranges, suitable environments, and safety certifications offer valuable insights to users, guiding them in making informed decisions. Moreover, customer testimonials and reviews play a pivotal role in establishing trust. Real-world performance feedback allows prospective users to gauge the tape’s effectiveness and reliability in various scenarios, fostering confidence in their choice. In conclusion, high heat electrical tape is more than just an insulating material; it is a critical component in ensuring the safety and integrity of electrical systems operating under extreme conditions. Its development and application are underscored by experience, expertise, authority, and trustworthiness. For professionals involved in high stakes environments—where every component's reliability matters—choosing the right high heat electrical tape is a decision that delivers both efficiency and peace of mind. As industries continue to evolve, the demand for superior materials capable of meeting new challenges will only grow, highlighting the indispensable role of high heat electrical tape in modern electrical engineering.

Moreover, manufacturer grades often specify the temperature range a particular high heat electrical tape can endure, alongside additional characteristics like tensile strength and elongation. Expertise in this domain guides electricians in selecting the right type of tape, ensuring the safety and efficiency of complex electrical systems. The authority of high heat electrical tape is backed by stringent testing and compliance with industry standards. Reputable manufacturers conduct rigorous assessments, ensuring their products meet or exceed safety regulations. This includes tests for flame retardancy, thermal conductivity, and chemical resistance. Such validation not only assures users of the tape’s performance under extreme conditions but also underscores the manufacturer’s commitment to quality. Given the critical applications of electrical tapes, authoritative endorsements provide users with peace of mind, knowing their safety measures are failproof. Trustworthiness in high heat electrical tape hinges on transparent communication from manufacturers regarding the tape’s capabilities and limitations. Labels specifying the temperature ranges, suitable environments, and safety certifications offer valuable insights to users, guiding them in making informed decisions. Moreover, customer testimonials and reviews play a pivotal role in establishing trust. Real-world performance feedback allows prospective users to gauge the tape’s effectiveness and reliability in various scenarios, fostering confidence in their choice. In conclusion, high heat electrical tape is more than just an insulating material; it is a critical component in ensuring the safety and integrity of electrical systems operating under extreme conditions. Its development and application are underscored by experience, expertise, authority, and trustworthiness. For professionals involved in high stakes environments—where every component's reliability matters—choosing the right high heat electrical tape is a decision that delivers both efficiency and peace of mind. As industries continue to evolve, the demand for superior materials capable of meeting new challenges will only grow, highlighting the indispensable role of high heat electrical tape in modern electrical engineering.

Latest news

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025