The Benefits and Applications of Heat Proof Electrical Tape

In today’s fast-paced world, ensuring the safety and efficiency of electrical systems is paramount. As technology advances, the materials and tools we use for electrical work must also evolve. One indispensable tool in this domain is heat proof electrical tape. This versatile product not only enhances safety but also extends the lifespan of electrical installations.

What is Heat Proof Electrical Tape?

Heat proof electrical tape is a specialized type of adhesive tape designed to resist high temperatures. Unlike standard electrical tape, which may deteriorate or lose its adhesive properties when exposed to heat, heat proof tape maintains its integrity under extreme conditions. This is particularly important in applications where heat dissipation is critical, such as in motors, transformers, and various electrical components that generate heat during operation.

Key Features

Heat proof electrical tape boasts several key features that set it apart from regular electrical tape

1. Temperature Resistance One of the most significant advantages of heat proof electrical tape is its ability to withstand high temperatures without melting or degrading. Most heat proof tapes can endure temperatures ranging from 105°C (221°F) up to 260°C (500°F) or more.

2. Insulation Properties This type of tape provides excellent electrical insulation, making it suitable for high-voltage applications. The material used in heat proof tapes often includes silicone, polyimide, or fiberglass, which all contribute to strong insulation against electrical currents.

3. Durability Heat proof electrical tape is generally more durable than regular tape. It is resistant to heat, moisture, and mechanical wear, making it ideal for various environments, including industrial settings where equipment may be exposed to harsh conditions.

4. Ease of Use Heat proof electrical tape is easy to apply, and it can be cut to size effortlessly, enabling electricians and technicians to use it effectively in various applications without specialized tools.

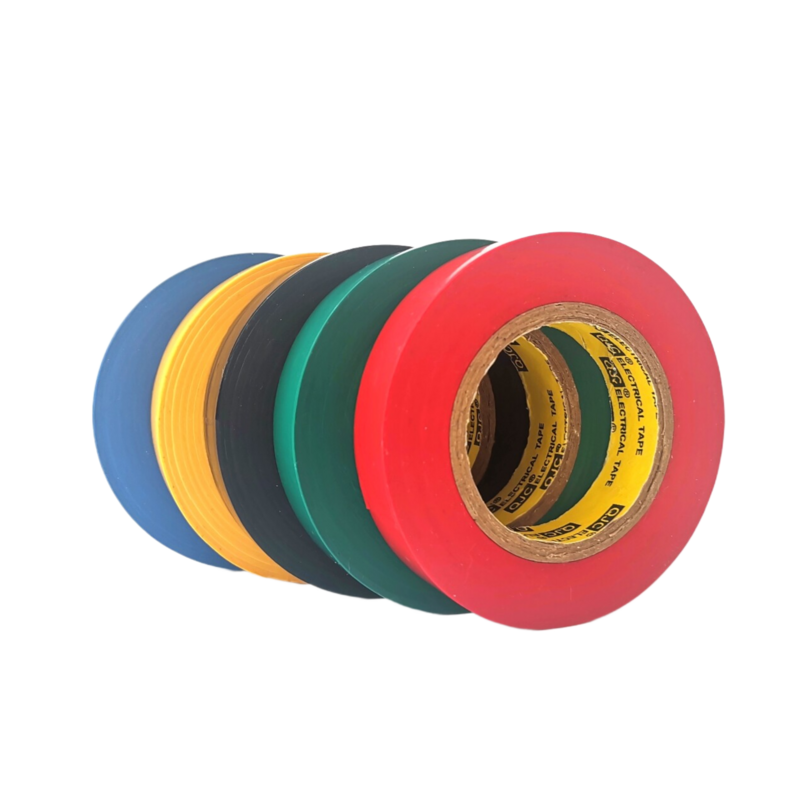

heat proof electrical tape

Applications

Heat proof electrical tape is utilized in a wide array of applications due to its robustness and reliability

1. Electrical Insulation It serves as an effective insulator for wires and cables, especially in automotive and aerospace industries where components are subjected to high temperatures and vibration.

2. Motor and Generator Repairs In electric motors and generators, heat proof tape is often used for securing and insulating winding connections, ensuring that the performance and safety standards are met.

3. Transformers Transformers generate significant heat when in operation. Heat proof electrical tape is crucial for protecting and insulating wire connections within transformers.

4. Home Appliance Repairs For DIY enthusiasts and professionals alike, heat proof tape is invaluable for repairs on appliances that may become hot during usage, including toasters, ovens, and dryers.

5. Industrial Applications Many industrial processes involve high heat environments. Heat proof tape is essential in factories and plants where temperature management is critical for equipment operation.

Conclusion

In conclusion, heat proof electrical tape is a vital component in both residential and industrial electrical systems. Its unique properties, including high temperature resistance, excellent insulation capabilities, and durability, make it an essential tool in ensuring the safety and efficiency of electrical installations. Whether you are an electrician, a technician, or a DIY enthusiast, incorporating heat proof electrical tape into your toolkit will provide you with added assurance and longevity for your electrical projects. As technology continues to advance, the significance of such specialized materials will only become more apparent, ensuring that your electrical systems remain safe and effective for years to come.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025