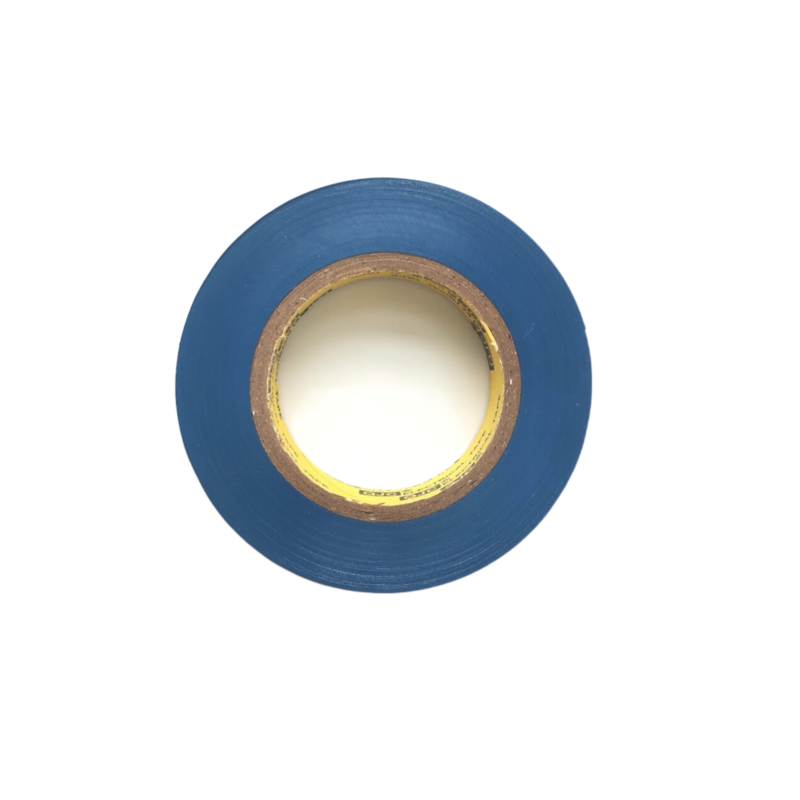

auto electrical cloth tape

Back to list

Jan . 23, 2025 03:42

Cloth electrical tape, a staple in both professional and DIY settings, represents an important tool in electrical and automotive applications. Combining flexibility and durability, it is an asset in maintaining electrical systems. This article dives deep into its advantages, applications, and expert advice to maximize your use of cloth electrical tape.

Being both expert and authority on the matter means recognizing the limitations and offering solutions. Although cloth electrical tape excels in most scenarios, it's crucial to be aware of its limits in terms of water resistance compared to rubber or silicone-based tapes. Consequently, experts recommend cloth tape for indoor or controlled environments, where exposure to moisture is limited. For outdoor connections or in areas exposed to splashes, preemptive measures or employing a combination solution involving moisture-resistant overlays can effectively extend the tape's lifespan. Trustworthiness in its performance also stems from its compliance with industry standards. When purchasing, look for certifications such as UL (Underwriters Laboratories) approval, ensuring the tape meets rigorous safety and performance benchmarks. Moreover, the trust invested by professionals who have utilized these tapes for decades in critical applications without failure, speaks volumes to their reliability. Ultimately, cloth electrical tape represents more than just a binding tool; it is a safeguard for the electrical continuity and mechanical resilience critical to numerous industries. Its deployment by knowledgeable practitioners underscores its value. Whether establishing initial connections or carrying out routine repairs, the ability of cloth electrical tape to offer a robust, reliable, and flexible solution establishes it as essential in any toolkit. Furthermore, its role in safety and efficiency directly contributes to minimizing electrical mishaps and enhancing operational preciseness, validating its consistent use across varied sectors. Sharing real experiences and expert insights encourages informed choices. As this tape continues to evolve with technological advancements, it remains an indispensable element in the electrical and automotive fields, seamlessly adapting to new demands while maintaining its commended reliability.

Being both expert and authority on the matter means recognizing the limitations and offering solutions. Although cloth electrical tape excels in most scenarios, it's crucial to be aware of its limits in terms of water resistance compared to rubber or silicone-based tapes. Consequently, experts recommend cloth tape for indoor or controlled environments, where exposure to moisture is limited. For outdoor connections or in areas exposed to splashes, preemptive measures or employing a combination solution involving moisture-resistant overlays can effectively extend the tape's lifespan. Trustworthiness in its performance also stems from its compliance with industry standards. When purchasing, look for certifications such as UL (Underwriters Laboratories) approval, ensuring the tape meets rigorous safety and performance benchmarks. Moreover, the trust invested by professionals who have utilized these tapes for decades in critical applications without failure, speaks volumes to their reliability. Ultimately, cloth electrical tape represents more than just a binding tool; it is a safeguard for the electrical continuity and mechanical resilience critical to numerous industries. Its deployment by knowledgeable practitioners underscores its value. Whether establishing initial connections or carrying out routine repairs, the ability of cloth electrical tape to offer a robust, reliable, and flexible solution establishes it as essential in any toolkit. Furthermore, its role in safety and efficiency directly contributes to minimizing electrical mishaps and enhancing operational preciseness, validating its consistent use across varied sectors. Sharing real experiences and expert insights encourages informed choices. As this tape continues to evolve with technological advancements, it remains an indispensable element in the electrical and automotive fields, seamlessly adapting to new demands while maintaining its commended reliability.

Latest news

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025