High Temperature Insulation Tape A Comprehensive Overview

In various industrial and commercial applications, maintaining optimal temperature control is crucial for the longevity and efficient operation of machinery, electronics, and other components. Among the tools employed for thermal management, high temperature insulation tape stands out as a vital resource. This specialized tape is engineered to withstand extreme temperatures while providing excellent electrical insulation, making it invaluable in numerous settings.

Materials and Properties

High temperature insulation tapes are typically made from materials such as polyimide, fiberglass, or silicone. Polyimide tape, for instance, can endure temperatures reaching up to 260°C (500°F), making it ideal for applications such as electronics manufacturing and aerospace. Fiberglass tapes are often used for heavy-duty insulation, providing durability and resistance to harsh environmental conditions. Silicone-based tapes, known for their flexibility and resilience, are commonly used in automotive and HVAC applications.

One of the key properties of high temperature insulation tape is its adhesive strength. The adhesive used in these tapes is formulated to remain effective even under extreme heat, ensuring that the tape adheres securely to surfaces. This is crucial in preventing debris ingress and maintaining a secure seal in high-temperature applications.

Applications

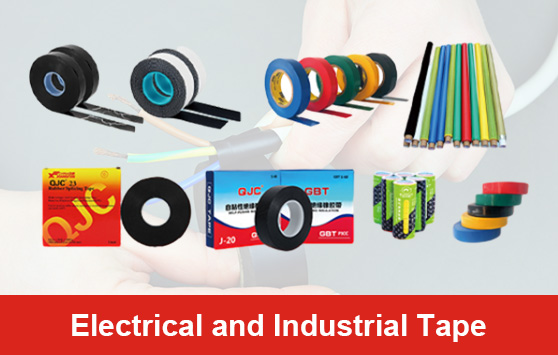

high temperature insulation tape

The versatility of high temperature insulation tape makes it suitable for a wide range of applications. In the electrical industry, it is often used for insulation of wires and cables that are subjected to high temperatures. This helps prevent electrical shorts and ensures reliable circuit operation. In the automotive sector, it is employed to wrap hoses, wires, and components that are exposed to heat, protecting them from damage and enhancing their lifespan.

Additionally, high temperature insulation tape is widely used in the aerospace industry, where it serves to insulate sensitive components and enhance safety. In manufacturing environments, it’s applied in situations where heat-resistant materials are needed to wrap machinery or tools, providing extra protection against thermal damage. Furthermore, this tape can also be utilized in homes for insulation around heating elements, ensuring efficiency in energy consumption.

Benefits

The primary benefits of high temperature insulation tape include its heat resistance, electrical insulating properties, durability, and versatility. Users can rely on this tape in extreme conditions without the fear of degradation or failure. Moreover, the ease of application allows for rapid installation, reducing downtime in critical operations. Given its cost-effectiveness, it proves to be an invaluable investment for businesses looking to enhance their operational efficiency.

Conclusion

High temperature insulation tape plays a critical role in various industries by ensuring equipment operates efficiently under extreme conditions. Its ability to withstand high temperatures, coupled with excellent adhesive properties and versatility, makes it an essential tool for electrical insulation, automotive applications, aerospace engineering, and manufacturing processes. As industries continue to evolve and demand greater energy efficiency and safety, the importance of high temperature insulation tape is set to grow, reinforcing its place as a pivotal component in modern technology and industrial practices.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025