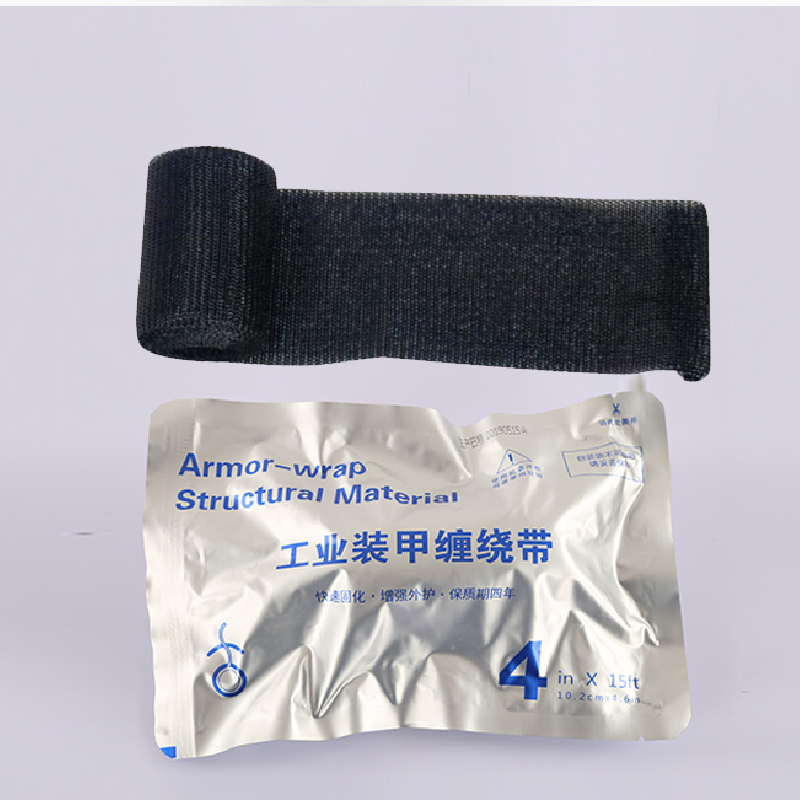

amalgamating tape

Back to list

Februari . 13, 2025 01:51

In the world of industrial applications and home DIY projects, amalgamating rubber tape stands out as a unique solution. Its self-bonding properties, versatility, and durability make it an essential tool in electrical work, plumbing, and various repair scenarios. This article explores the intricate details of amalgamating rubber tape, showcasing real-world experiences, professional insights, and reasons why it is highly regarded in numerous industries.

Trustworthiness A key reason that professionals trust amalgamating rubber tape is its proven track record. Over the years, it has consistently performed well in both controlled laboratory tests and real-world conditions. Its resilience in adverse weather, resistance to UV exposure, and ozone degradation ensure its long-term performance. Additionally, being free from degradative ingredients and toxins reassures users who prioritize environmentally sustainable solutions. Application Scenarios Amalgamating rubber tape finds its use in diverse settings. In marine environments, where exposure to water and salt is constant, it is used to seal cable connections and prevent corrosion. In the automotive field, mechanics employ it to protect against oil and hydraulic fluid spills, providing a clean and lasting seal. Additionally, its thermal stability makes it suitable as a temporary fix for hot water piping and around boiler systems in emergency scenarios. Selection Considerations When choosing amalgamating rubber tape, it is vital to consider factors like the operating environment, application type, and required durability. Various thicknesses and widths are available, and selecting the appropriate specification ensures optimal performance. Experts advise checking manufacturer data sheets for tensile strength, elongation capacity, and temperature rating to match specific project needs. Conclusion Amalgamating rubber tape serves as a critical tool for both professional technicians and DIY enthusiasts. Its unique self-bonding properties offer unmatched performance across various applications and industries. When used correctly, it provides reliable, long-term solutions that ensure operational success and safety. With its combination of flexibility, resilience, and proven effectiveness, amalgamating rubber tape remains indispensable, underscoring its status as a trusted choice for nearly any sealing or insulation task.

Trustworthiness A key reason that professionals trust amalgamating rubber tape is its proven track record. Over the years, it has consistently performed well in both controlled laboratory tests and real-world conditions. Its resilience in adverse weather, resistance to UV exposure, and ozone degradation ensure its long-term performance. Additionally, being free from degradative ingredients and toxins reassures users who prioritize environmentally sustainable solutions. Application Scenarios Amalgamating rubber tape finds its use in diverse settings. In marine environments, where exposure to water and salt is constant, it is used to seal cable connections and prevent corrosion. In the automotive field, mechanics employ it to protect against oil and hydraulic fluid spills, providing a clean and lasting seal. Additionally, its thermal stability makes it suitable as a temporary fix for hot water piping and around boiler systems in emergency scenarios. Selection Considerations When choosing amalgamating rubber tape, it is vital to consider factors like the operating environment, application type, and required durability. Various thicknesses and widths are available, and selecting the appropriate specification ensures optimal performance. Experts advise checking manufacturer data sheets for tensile strength, elongation capacity, and temperature rating to match specific project needs. Conclusion Amalgamating rubber tape serves as a critical tool for both professional technicians and DIY enthusiasts. Its unique self-bonding properties offer unmatched performance across various applications and industries. When used correctly, it provides reliable, long-term solutions that ensure operational success and safety. With its combination of flexibility, resilience, and proven effectiveness, amalgamating rubber tape remains indispensable, underscoring its status as a trusted choice for nearly any sealing or insulation task.

Next:

Latest news

-

Types of Electrical and Industrial Tape and Their DifferencesNewsAug.04,2025

-

The Versatile Uses of Rubber Tape in Daily LifeNewsAug.04,2025

-

Key Features of Automotive Wire Harness PVC TapeNewsAug.04,2025

-

Key Benefits of Using Linerless Insulating Rubber Tape in Electrical WorkNewsAug.04,2025

-

How to Choose the Right Rubber TapeNewsAug.04,2025

-

How to Apply PVC Warning and Floor Marking Tape for Maximum DurabilityNewsAug.04,2025