The Versatility of Black Tack Butyl A Comprehensive Overview

Black tack butyl is a remarkable material renowned for its adhesive properties and versatility in various applications. This unique substance, primarily made from butyl rubber, combines excellent elasticity with strong bonding capabilities, making it a preferred choice in industries ranging from construction to automotive.

One of the standout features of black tack butyl is its inherent resistance to weathering, aging, and environmental stressors. Unlike conventional adhesives, black tack butyl can withstand extreme temperatures and harsh weather conditions without losing its effectiveness. This resilience makes it particularly advantageous for outdoor applications, such as roofing and sealing, where exposure to moisture and ultraviolet light can degrade other materials.

Additionally, black tack butyl is known for its exceptional soundproofing qualities. Its dense composition allows it to absorb sound vibrations effectively, making it an ideal choice for acoustic insulation within buildings, vehicles, and machinery. This property is invaluable in creating quieter environments, contributing to overall comfort and productivity.

In the realm of construction, black tack butyl serves multiple purposes. It is widely used as a sealing agent for windows, doors, and roofing systems, preventing air and water infiltration. Its strong adhesion ensures that it remains in place over time, safeguarding buildings from potential damage caused by leaks or drafts. Furthermore, black tack butyl is often utilized in the manufacturing of gaskets and seals for various mechanical applications, enhancing the integrity and performance of machinery.

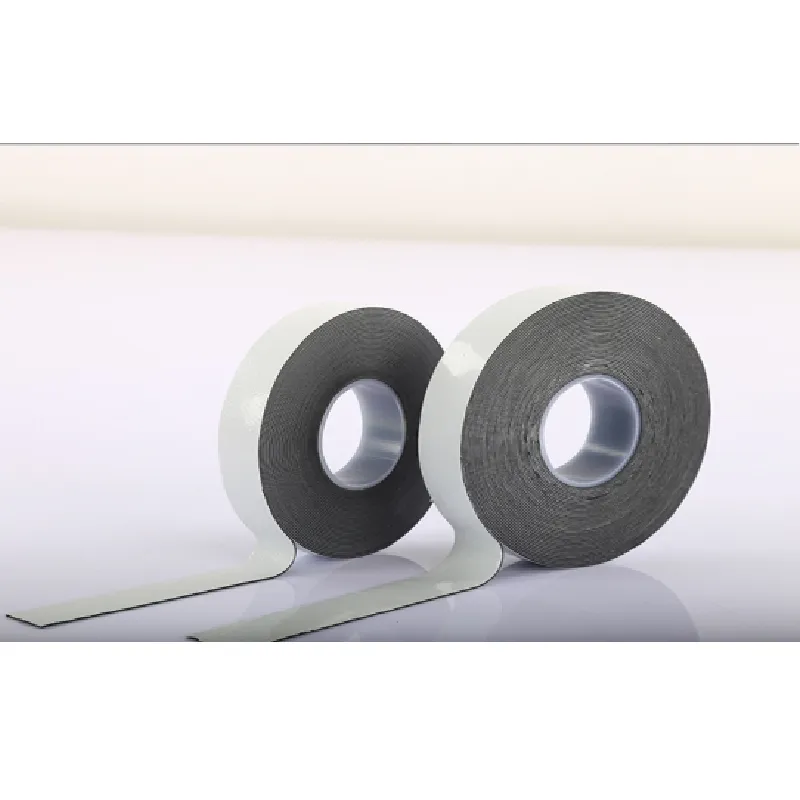

black tack butyl

The automotive industry also benefits significantly from black tack butyl. It is commonly used in the assembly of vehicles to bond glass to metal frames and provide a watertight seal. This not only improves the vehicle's durability but also enhances passenger comfort by minimizing noise and vibration. With the growing emphasis on energy efficiency and sustainability, the demand for reliable sealing solutions like black tack butyl has surged, further solidifying its importance in modern automotive engineering.

Another noteworthy aspect of black tack butyl is its ease of application. It is available in various forms, including sheets, tapes, and liquid adhesives, which allows for flexibility and convenience in usage. This adaptability enables contractors and manufacturers to choose the most suitable product for their specific needs, facilitating efficient installation and long-lasting results.

Despite its many advantages, it is essential to handle black tack butyl with care. While it is generally safe, prolonged exposure to certain solvents or operating conditions can lead to degradation. Therefore, adhering to manufacturer guidelines and conducting regular maintenance checks is crucial to ensure its optimal performance.

In conclusion, black tack butyl stands out as a multifunctional material, offering numerous benefits across diverse industries. Its superior adhesive properties, weather resistance, soundproofing capabilities, and ease of application make it a vital component in construction, automotive, and beyond. As technology advances and the demand for reliable materials continues to grow, black tack butyl is poised to play an even more significant role in shaping the future of modern engineering and construction practices. Whether sealing a roof or bonding components in a vehicle, the impact of black tack butyl is undeniable, making it an invaluable asset in today’s manufacturing landscape.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025