The Importance of Electrical Harness Tape in Modern Industries

In the world of manufacturing and engineering, electrical harnesses play a crucial role in the functionality and efficiency of various systems. Electrical harness tape is an essential component in the assembly and protection of wiring harnesses, ensuring that electrical systems operate safely and efficiently. This article explores the significance of electrical harness tape, its applications, and benefits across different industries.

What is Electrical Harness Tape?

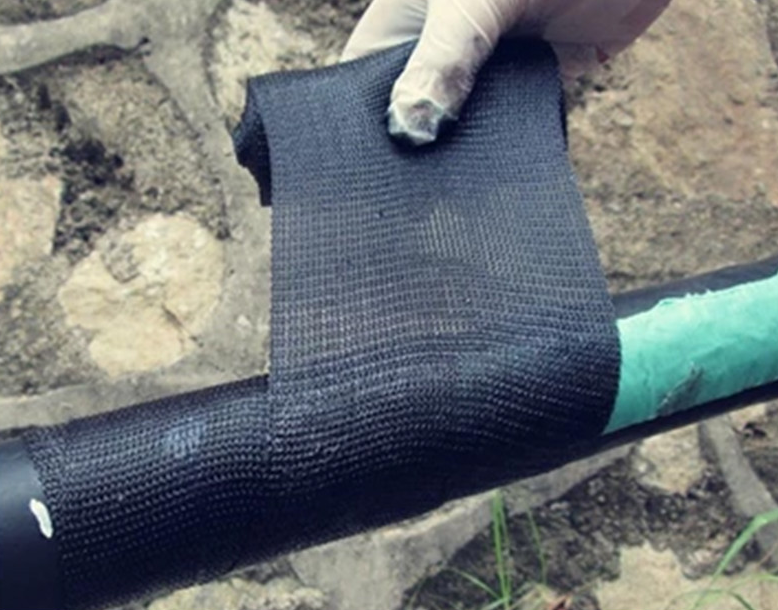

Electrical harness tape, also known as wiring harness or insulation tape, is a specialized tape used to bundle, insulate, and protect wires and cables within an electrical harness. It is designed to withstand the rigors of the electrical environment, including temperature variations, moisture, and mechanical stress. The tape typically features a strong adhesive backing and is made from materials like vinyl, polyester, or polyethylene, depending on the application requirements.

Applications of Electrical Harness Tape

Electrical harness tape is used across various industries, including automotive, aerospace, consumer electronics, and industrial machinery. In the automotive sector, for instance, it is vital for organizing and securing wiring in engines, dashboards, and various electronic modules. The tape helps prevent abrasion and damage to wires caused by vibration and movement, which can lead to electrical failures or shorts.

In aerospace applications, electrical harness tape is used to ensure the reliability of wiring systems in aircraft. Given the harsh environmental conditions at high altitudes, the tape must provide excellent insulation properties and resistance to extreme temperatures. Similarly, in consumer electronics, this tape is used to neatly bundle wires in devices such as smartphones, laptops, and home appliances, improving both aesthetics and functionality.

Benefits of Using Electrical Harness Tape

electrical harness tape

The advantages of using electrical harness tape are manifold. Firstly, it enhances safety by reducing the risk of electrical shorts and fires caused by frayed wires or exposed conductors. By providing a protective layer, the tape ensures that wiring systems operate within safe parameters, thus minimizing hazards.

Secondly, electrical harness tape improves organization. In complex systems where hundreds of wires are present, proper bundling and insulation help technicians and engineers quickly identify and troubleshoot issues. This organized approach reduces maintenance time and increases operational efficiency.

Moreover, the durability of electrical harness tape is a significant benefit. Many tapes are designed to withstand extreme temperatures, moisture, and UV exposure, ensuring that they maintain their integrity over time. This longevity translates to lower replacement costs and a reduced environmental impact, as less frequent replacements lead to less waste.

Customization and Innovation

With the growing demand for specialized electrical harness solutions, manufacturers are increasingly offering customized electrical harness tape to meet specific industry needs. Options for varying widths, colors, and adhesive strengths allow for tailored solutions that address unique application requirements.

Innovation in materials is also advancing the capabilities of electrical harness tape. For instance, the development of self-adhesive tapes makes installation simpler and quicker, while advanced insulation materials enhance performance under extreme conditions.

Conclusion

In summary, electrical harness tape is a vital component in the construction and protection of wiring harnesses across various industries. Its ability to bundle, insulate, and protect wires not only enhances safety and efficiency but also contributes to the longevity of electrical systems. With innovations constantly emerging in materials and customization options, the future of electrical harness tape is promising, ensuring that it continues to play a fundamental role in the reliable operation of electrical systems. As industries evolve and technology becomes more sophisticated, the demand for effective and durable electrical harness solutions will undoubtedly increase, placing electrical harness tape at the forefront of such advancements.

-

The Versatility of Cloth Insulation TapeNewsApr.07,2025

-

The Power of Self Amalgamating Silicone TapeNewsApr.07,2025

-

The Importance of Weatherstrip Seal: Your Ultimate Protection SolutionNewsApr.07,2025

-

Tape Electrical Insulation: A Reliable Solution for Your Electrical NeedsNewsApr.07,2025

-

Discover the Wonders of Electrical Splicing TapeNewsApr.07,2025

-

Discover the Versatility of PVC Electrical TapeNewsApr.07,2025