Low Smoke and Halogen-freeSelf-bonding Fire-resistance Tape

Back to list

Februari . 18, 2025 01:04

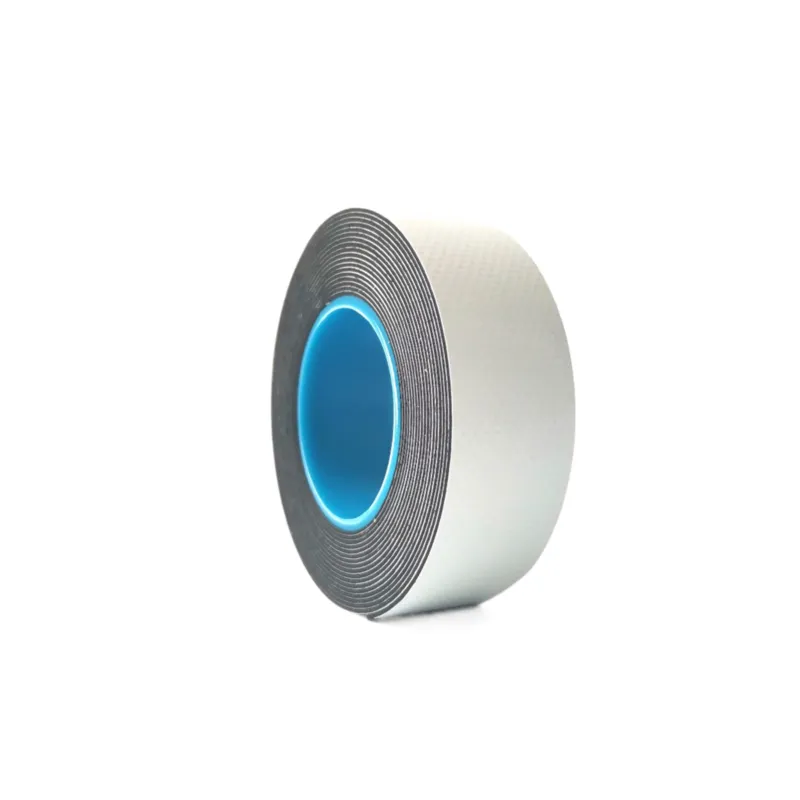

Fire resistant adhesive tape has transformed the way industries approach safety and efficiency in managing both everyday tasks and high-risk environments. This unique product merges cutting-edge technology with practicality, ensuring that a variety of sectors can work confidently under conditions that require extreme protection measures. Understanding this product's applications, functionality, and reliability is crucial for any business seeking to enhance safety protocols while maintaining operational excellence.

The application of fire resistant adhesive tape extends to sealing HVAC ductwork, which is often required to maintain performance in high-temperature environments. This is particularly relevant for industrial settings such as factories and large office buildings, where the ductwork must remain secure to prevent the spread of smoke and fire. Here, the tape’s authority is reinforced by its capability of sustaining structural integrity, thus preventing potentially life-threatening compromises in safety. On the manufacturing floor, machine operators and safety engineers depend on this tape to secure fittings and surfaces that might otherwise pose fire risks. It provides a trustworthy solution for lining or wrapping materials that require fire barrier protection. Additionally, workers in electrical safety environments apply these tapes as an extra precaution, ensuring circuits and connectors do not spark secondary fires, thus enhancing workplace safety. In facilitating trustworthiness, manufacturers of fire resistant adhesive tape often provide comprehensive data sheets and performance statistics. This documentation validates their commitment to quality, offering transparency about the tape's capabilities and limitations. Such practices not only establish trust but also guide users in choosing the appropriate tape based on specific requirements, ensuring optimal functionality and safety. In conclusion, fire resistant adhesive tape stands as a beacon of innovation and reliability. Its application across various industries continues to grow, revolutionizing safety standards and operational efficiencies. By choosing a product that underscores Experience, Expertise, Authoritativeness, and Trustworthiness, businesses not only align with industry best practices but also safeguard their most valuable assets their people, their equipment, and their future.

The application of fire resistant adhesive tape extends to sealing HVAC ductwork, which is often required to maintain performance in high-temperature environments. This is particularly relevant for industrial settings such as factories and large office buildings, where the ductwork must remain secure to prevent the spread of smoke and fire. Here, the tape’s authority is reinforced by its capability of sustaining structural integrity, thus preventing potentially life-threatening compromises in safety. On the manufacturing floor, machine operators and safety engineers depend on this tape to secure fittings and surfaces that might otherwise pose fire risks. It provides a trustworthy solution for lining or wrapping materials that require fire barrier protection. Additionally, workers in electrical safety environments apply these tapes as an extra precaution, ensuring circuits and connectors do not spark secondary fires, thus enhancing workplace safety. In facilitating trustworthiness, manufacturers of fire resistant adhesive tape often provide comprehensive data sheets and performance statistics. This documentation validates their commitment to quality, offering transparency about the tape's capabilities and limitations. Such practices not only establish trust but also guide users in choosing the appropriate tape based on specific requirements, ensuring optimal functionality and safety. In conclusion, fire resistant adhesive tape stands as a beacon of innovation and reliability. Its application across various industries continues to grow, revolutionizing safety standards and operational efficiencies. By choosing a product that underscores Experience, Expertise, Authoritativeness, and Trustworthiness, businesses not only align with industry best practices but also safeguard their most valuable assets their people, their equipment, and their future.

Latest news

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025