Understanding Automotive Wiring Loom Wrap Essential for Vehicle Safety and Performance

In the modern automotive industry, the importance of wiring looms cannot be overstated. They play a crucial role in ensuring that various electrical components in a vehicle function correctly. Among the pivotal elements in managing these wiring systems is the wiring loom wrap, an indispensable component that contributes to both safety and performance. This article delves into the significance of automotive wiring loom wrap, its benefits, types, and best practices for use.

What is a Wiring Loom Wrap?

A wiring loom wrap is a protective covering designed to encase and isolate electrical wires running throughout a vehicle’s structure. These wraps are made from various materials, including fabric, plastic, or rubber, each providing specific characteristics suited for different applications in automotive environments. A key function of the wiring loom wrap is to bundle together multiple wires, preventing tangling and reducing the chances of electrical interference.

Benefits of Using Wiring Loom Wrap

1. Protection Against Mechanical Damage One of the most critical roles of the wiring loom wrap is to safeguard the wires from mechanical wear and tear. This protection is essential in areas where wires may rub against metal components, reducing the likelihood of insulation deterioration and electrical shorts.

2. Environmental Resistance Automotive wiring systems are susceptible to harsh conditions, including heat, moisture, and exposure to chemicals. High-quality wrap can enhance the durability of wiring by providing additional resistance against these environmental factors, thus prolonging the lifespan of the electrical system.

3. Improved Aesthetics and Organization Using wiring loom wraps can significantly improve the appearance of an automotive wiring system by providing a clean and organized look. Bundling wires helps reduce clutter in the engine bay or interior, making maintenance and troubleshooting easier while enhancing visual appeal.

4. Electrical Insulation The wraps act as insulators which prevent electrical interference between wires. This is essential in modern vehicles, where numerous wires may run parallel to each other, carrying different signals. Proper insulation helps maintain optimal performance of electronic components, minimizing the risk of malfunctions.

5. Reduced Risk of Fire In the unfortunate event of wire damage, sparks can lead to short circuits, presenting a potential fire hazard. Wiring loom wraps serve as an added protective layer against such occurrences, significantly reducing the fire risk associated with exposed wiring.

Types of Wiring Loom Wrap

1. Heat Shrink Tubing Typically used at the ends of wires and connectors, heat shrink tubing shrinks to fit tightly around the wiring once heated, providing a secure protective covering that enhances insulation.

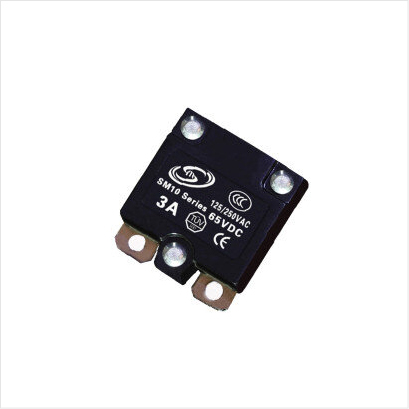

automotive wiring loom wrap

2. Fabric Loom Wrap This type is made from woven fabric, which provides excellent flexibility and abrasion resistance. Fabric wraps are often used in areas with extreme movement or where a higher level of protection against wear is required.

3. Plastic Loom Tubing Plastic wraps come in various sizes and can easily be cut to fit specific applications. They are lightweight and offer decent protection against environmental stressors.

4. Rubber Wrap Known for its durability and chemical resistance, rubber wraps are ideal for environments where exposure to oil or chemicals is a concern.

Best Practices for Using Wiring Loom Wrap

To achieve the best results from automotive wiring loom wraps, consider the following practices

- Choose the Right Material Assess the environment in which the wires will be used. Select a wrap that offers the right balance of flexibility, heat resistance, and protection.

- Ensure Clean Surfaces Before applying the wrap, make sure the surfaces of the wires are clean and free from dirt or grease to ensure a secure fit.

- Cut to Fit If using fabric or plastic wraps, measure and cut them to the appropriate length before installation to avoid exposing any wiring.

- Secure the Ends Always use zip ties, clips, or adhesive to secure the ends of the wraps to prevent slippage and ensure full coverage of the wiring.

Conclusion

In conclusion, automotive wiring loom wraps are a vital element that enhances safety, durability, and performance in vehicles. By effectively protecting the electrical systems, these wraps contribute to the overall reliability of modern automotive technology, making them indispensable for both manufacturers and DIY enthusiasts alike. Understanding the types of wraps available and implementing best practices for their use can lead to safer and more efficient vehicle operation.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025