The Versatility and Importance of Self-Amalgamating Tape

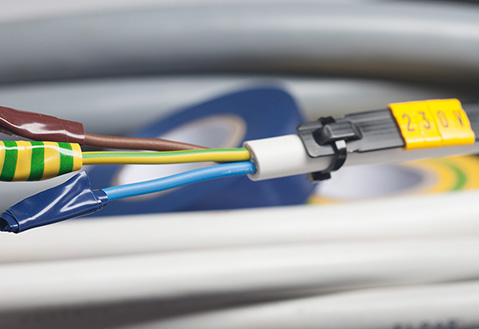

In the world of adhesives and seals, self-amalgamating tape, particularly the 50mm variety, stands out as a highly versatile and effective solution for a multitude of applications. This unique tape has found its place in various industries including electrical, automotive, plumbing, and even in everyday household uses. Its distinct properties make it a go-to product for both professionals and DIY enthusiasts alike.

Self-amalgamating tape, also known as self-fusing or self-bonding tape, is made from rubber or silicone-based materials that bond to themselves upon contact. This means that when wrapped around an object, the tape adheres to itself rather than to the surface below it. This property not only enhances the tape's ability to create a waterproof seal but also ensures a strong, durable finish without the need for additional adhesives or tools.

The Versatility and Importance of Self-Amalgamating Tape

Another noteworthy feature is its ability to withstand extreme temperatures. Self-amalgamating tape can maintain its integrity in environments ranging from -60°C to 260°C (-76°F to 500°F). This temperature resilience makes it suitable for high-stress applications, such as in automotive engines and electrical applications where heat is a concern. By providing reliable insulation and protection against heat and moisture, self-amalgamating tape effectively prolongs the life of components and enhances overall performance.

self amalgamating tape 50mm

In plumbing, the tape has gained popularity for its ability to quickly seal leaks and repair hoses. Unlike traditional tapes that require surface adhesion, self-amalgamating tape can be wrapped around wet or damp surfaces. This means that a simple leak can often be resolved with just a quick application of the tape, making it an invaluable tool for emergency repairs. Whether in residential settings or industrial locations, the tape's utility in plumbing cannot be overstated.

Moreover, the ease of application is one of the hallmarks of self-amalgamating tape. Users do not need specialized tools or skills to apply the tape effectively. It can be hand torn, and it adheres to itself easily, allowing for quick and straightforward repairs. For professionals working in challenging environments or with tight deadlines, this ease of use translates to efficiency and significant time savings.

Self-amalgamating tape is also non-toxic and safe for various uses, including in automotive and HVAC applications. This aspect makes it an excellent choice for environments where hazardous materials are a concern. Additionally, its non-corrosive nature ensures that it does not damage the surfaces to which it is applied, further extending its usability.

When it comes to storage, self-amalgamating tape is relatively easy to maintain. It does not have a finite shelf life in the same way that traditional adhesive tapes do since it only activates upon contact with itself. However, it is prudent to store it in a cool, dry area to preserve its properties.

In summary, self-amalgamating tape, particularly in the 50mm width, is a multi-purpose tool that offers an array of advantages across different sectors. Its self-fusing properties, excellent insulation capabilities, temperature resilience, and ease of use make it an essential item for anyone involved in repair work or maintenance. As technology continues to advance, the applications for self-amalgamating tape will likely expand, confirming its place as a vital resource in both professional and domestic settings. Embracing such innovative solutions is crucial for improving efficiency and ensuring reliability in everyday tasks.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025