In 2024, the global butyl sealing tape market reached USD 721 million, with an expected CAGR of 5.6% through 2028 (Source: Markets & Markets). This growth is fueled by expanded application in construction, automotive, petrochemical, and HVAC industries, thanks to exceptional sealing reliability, climate adaptability, and eco-friendliness. The adoption of advanced butyl rubber sealant tape technologies and new manufacturing standards such as ISO 9001:2015 further boost product performance and customer trust.

| Parameter | Butyl Rubber Tape | Butyl Rubber Flashing Tape | Generic Rubber Tape |

|---|---|---|---|

| Base Material | Butyl Rubber, Polyethylene Film | Butyl Rubber, Aluminum Foil | Natural Rubber |

| Thickness (mm) | 0.5 - 3.0 | 0.8 - 2.2 | 0.5 - 1.5 |

| Width (mm) | 30 - 1200 | 50 - 600 | 20 - 80 |

| Tensile Strength (MPa) | 1.6 - 2.3 | 1.2 - 1.7 | 0.9 - 1.3 |

| Elongation at Break (%) | 400-500 | 320-420 | 200-300 |

| Adhesion (N/cm) | 20 - 23 | 16 - 20 | 8 - 13 |

| Service Life (years) | 20+ | 10-15 | 3-5 |

| Temperature Range (°C) | -40 to 120 | -30 to 100 | -10 to 70 |

| Waterproof Rating | Class I (0.92-1.1MPa) | Class II (0.7-0.89MPa) | Class III |

| Certifications | ISO 9001:2015, SGS | CE, ROHS | --- |

- Superior Elasticity & Elongation: With elongation at break exceeding 400%, butyl tapes offer outstanding flexibility even under thermal cycling.

- Outstanding Waterproofing & Corrosion Protection: Certified to ISO 9001:2015 and passed SGS Verification.

- Excellent Adhesion: Maintains adhesion strength ≥ 20 N/cm even in humid, low temp, or oily environments.

- UV, Heat, and Chemical Resistance: Withstands -40ºC to 120ºC without aging or cracking.

- Environmental Performance: Low VOC, non-solvent, RoHS-compliant. No harmful outgassing in HVAC or electronics.

| Manufacturer | Key Products | Certifications | Lead Time | Customization | Global Clients |

|---|---|---|---|---|---|

| Qiangda Tape | Butyl Rubber Tape, Flashing Tape | ISO 9001:2015, SGS | 7~15 days | Yes (OEM/ODM, color/size) | ExxonMobil, Sinopec, Ikea |

| Bostik SA | Butyl Sealant Tape | REACH, RoHS | 14~25 days | No/limited | Saint-Gobain, Audi |

| Tremco Inc. | Butyl Mastic, Flashing Tape | UL, CE | 10~21 days | Limited | Skanska, Hilti |

| 3M | Specialty Butyl Tape | ISO 14001, ASTM | 20~30 days | No | JCI, GM |

Qiangda offers fully customized butyl sealing tape to adapt to complex environments and regulatory needs:

- Size and Thickness: Up to 1200mm wide, 0.3mm–5mm thick

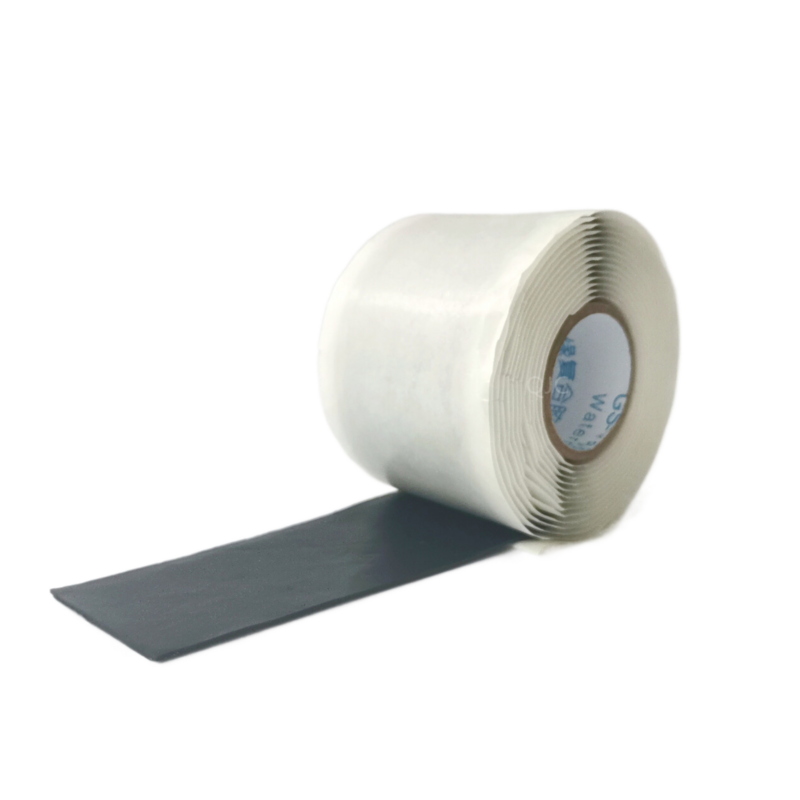

- Backing Choices: Aluminum foil (for UV/thermal reflection), Non-woven, PE, EPDM, or PET films

- Adhesive Strength: Can be optimized for cold, oily, or powder-coated surfaces

- Color/Finishing: Silver, black, white, translucent, logo printing for project branding

- Sector-specific: Infrastructure, pipeline, curtain wall, automotive, UAV, solar energy, etc.

- Compliance: Unique formulations to meet EN 1931, ASTM D-903, RoHS, CE as needed

- Samples: 3–5 days

- Volume orders: 7–20 days (depending on specs)

-

Pipeline Anti-corrosion (Petrochemical)In a 2023 Sinopec pipeline maintenance project in Qingdao, Qiangda's butyl rubber tape provided Class I waterproofing per ISO 4628, with on-site adhesion ≥ 21 N/cm, cutting downtime by 42% vs. asphalt tapes.

-

Metal Roofing/Flashing (Construction)An IKEA logistics park used Qiangda butyl rubber flashing tape to seal 4800m of expansion joints, maintaining no visible leakage after 6 monsoon cycles.

-

Underground Waterproofing (Subway/Metro)Metro Guangzhou Line 21 adopted wide-width butyl sealing tape for segmental tunnel gaskets under the ASTM D-376 water infiltration standard, ensuring water permeability < 0.2g/24h•m².

-

Automotive Door & Headlight SealingAutomotive client BYD improved assembly line efficiency by 22% using butyl tape rubber in vehicle sealing, reducing post-assembly leakage complaints.

-

Solar Farm Mounting/UV BarrierSolar field in Rajasthan (India) reports zero corrosion at panel supports after three years' exposure >50°C, using Qiangda butyl rubber tape with UV-reflective film.

- Lead Time: Standard SKUs: 7–15 days | Customized: up to 20 days

- Warranty: 10 years material warranty (full replacement for proven defects); technical solutions backed by 20+ years’ industry experience.

- Support: Pre-sale project consulting, installation training, tape selection advice, after-sale technical service; response within 2 working hours.

- Third-party test reports, international ISO/SGS certificates, and project references can be provided upon request, reinforcing trust & transparency.

Butyl sealing tape demonstrated consistently outstanding performance in weather resistance, adhesion, and versatility over the past decade. With the advancement of eco-friendly materials and intelligent manufacturing (CNC, ISO compliance), it has become the premium choice for global sealing and waterproofing solutions.

- Materials & Performance Analysis: American Chemical Society Polymer Journals

- Industry Discussions: SpecialChem Adhesives Forum

- Testing Standards: ISO 9001:2015, ISO/ASTM Norms

- News on Sealing Innovations: Insulation Outlook 2022

- Practical Experiences: ContractorTalk (Butyl Tape Experiences)

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025