Analyzing J30 High-voltage EPR Rubber Tape:

Technical Data, Manufacturing Process, Applications, and Market Comparison

EPR Self Amalgamating Tape: Market Overview & Industry Trends

EPR Self Amalgamating Tape—an essential material in power, petrochemical, and industrial fields—has seen rapid growth driven by the demand for efficient, high-insulation, and weather-resistant cable protection solutions. According to MarketsandMarkets, global demand for self-amalgamating tapes exceeded USD 580 million in 2023, with EPR-based products accounting for over 33% due to their unique properties.

EPR tape (Ethylene Propylene Rubber Tape) stands out for its high electrical insulation, self-fusing capability, and superior aging resistance. The proliferation of renewable energy generation, smart grid infrastructure, and the expansion of subsea cabling in offshore wind are propelling the market further.

Explore more about epr self amalgamating tape solutions and the best tape for high-voltage cable jointing.

What is EPR Self Amalgamating Tape?

EPR self amalgamating tape is made from premium ethylene propylene rubber. It is non-tacky until overlapped, upon which it instantly fuses to form a homogeneous layer without external heat or pressure. This provides reliable electrical insulation, water-tightness, and chemical inertness, making it a vital material for cable splicing, corrosion protection, and mechanical waterproofing.

- Voltage Withstand: Up to 69kV, widely used in 11kV, 22kV, and 33kV class cables.

- Self-Amalgamating: Bonds to itself without adhesives, ensuring seamless encapsulation and protection.

- Weather & Aging Resistance: Withstands UV, ozone, and wide temperature swings.

Technical Specification Table: EPR Self Amalgamating Tape

| Parameter | Typical Value | Test Standard | Industry Reference |

|---|---|---|---|

| Base Material | Ethylene Propylene Rubber (EPR) | ASTM D4388 | ASTM |

| Thickness | 0.76 ±0.05 mm | ISO 4593 | Industry Avg: 0.75mm |

| Elongation at Break | >900% | ISO 37 | ±50% over PVC tapes |

| Dielectric Strength | >40 kV/mm | IEC 60243-1 | IEC ref. 35-45 kV/mm |

| Operating Temp. Range | -40°C to +100°C | IEC 60454 | ISO typical: -35~90°C |

| Water Absorption | ISO 62 | Low | |

| Adhesion to Steel | No adhesive required; Fuses to Itself | Internal | Industry property |

| UV/Ozone Resistance | Excellent | EN 13859 | Long-life |

Manufacturing Process of EPR Self Amalgamating Tape

Manufacturing epr self amalgamating tape involves multiple advanced stages to optimize purity, performance, and consistency. Here is a graphical walkthrough:

Key manufacturing advantages:

- High-volume CNC-controlled extrusion lines ensure dimensional accuracy and product repeatability.

- Complies with ISO 9001:2015, ANSI/EIA S-6, and IEC standards throughout.

- Automated online thickness & conductivity monitoring for zero-defect production.

Application Scenarios of EPR Self Amalgamating Tape

- Power Cable Jointing/Repair: Used extensively in 11-69kV cable splicing, especially where moisture/seawater ingress is a risk.

- Substation & Switchgear: Providing mechanical and electrical protection in confined, high-humidity, or corrosive locations.

- Oil & Gas Pipelines: Wrapping over metallic and composite pipelines to prevent corrosion in marine or underground service.

- Infrastructure: Building water-proofing, telecom mast terminations, and wind turbine cable management.

- Metallurgical and Petrochemical Plants: Withstands chemical fumes, temperature shocks, and mechanical abrasion.

Case Highlight: Offshore Wind Farm Cable Protection

In the 2023 Tianjin Offshore Wind Project, J30 High-voltage EPR Rubber Tape was selected to wrap sub-sea 33kV connection joints due to exceptional dielectric performance (>42kV/mm tested, see below). Its self-fusing capability drastically reduced installation time by 40% and cut maintenance downtime by half compared to imported alternatives.

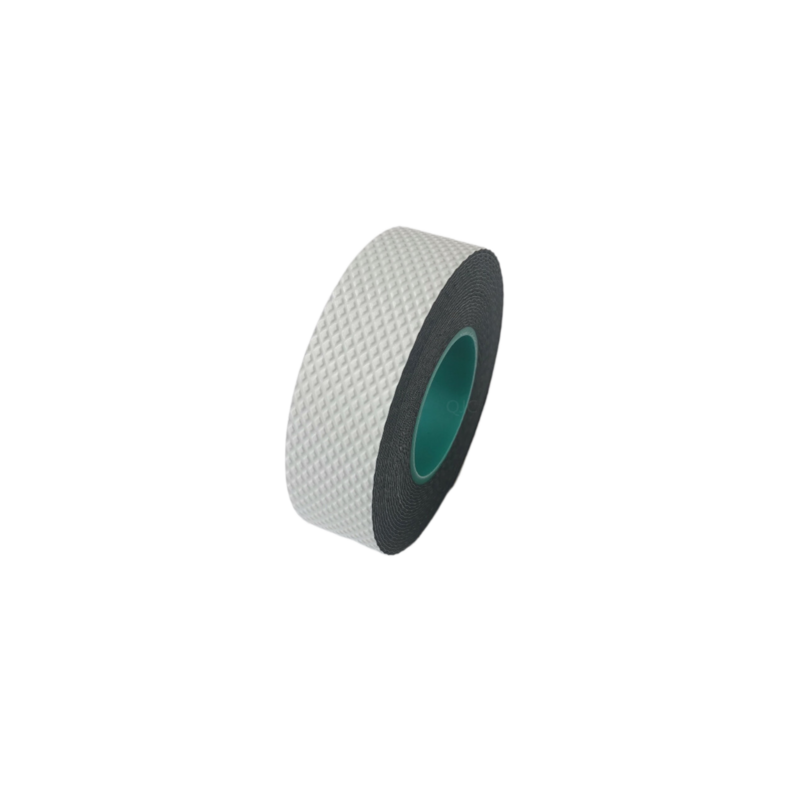

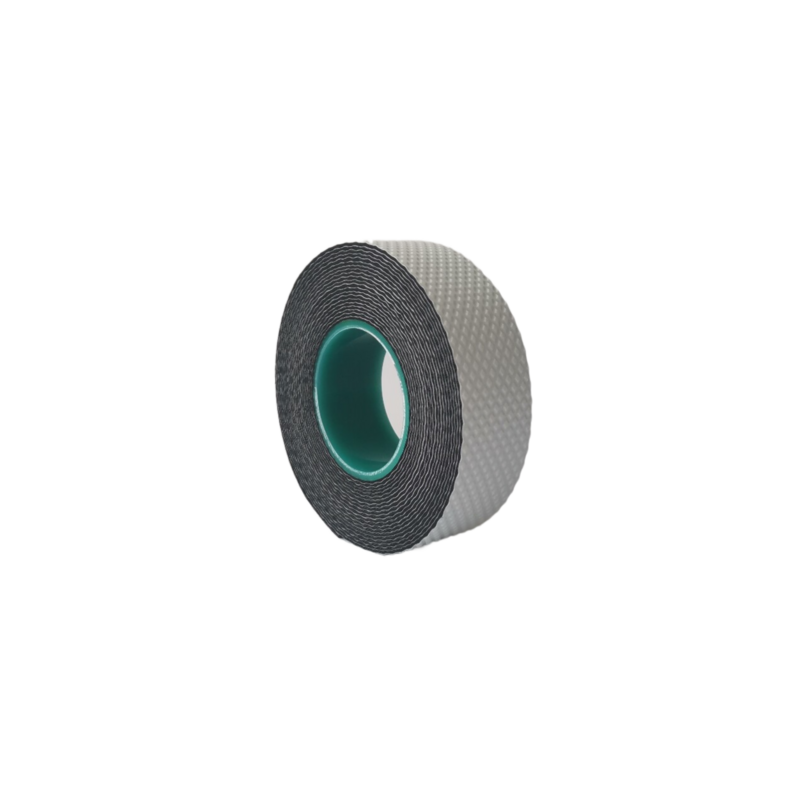

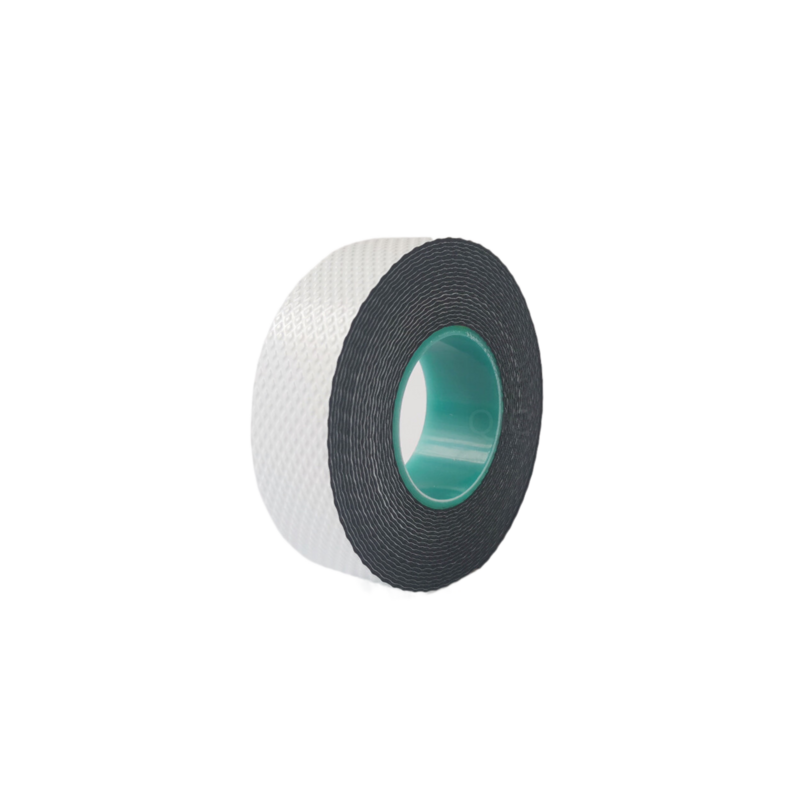

Spotlight Product: J30 High-voltage EPR Rubber Tape

J30 High-voltage EPR Rubber Tape is engineered for 35kV~69kV cable splicing, with robust weather and chemical resistance. Here's how it stands apart:

- Material: 100% virgin high-grade EPR, free from fillers/adulteration.

- Thickness Control: 0.76±0.03mm, ensuring dielectric uniformity.

- Electrical Strength: 41-45kV/mm tested (ASTM D4388).

- Extended Life: >25 years in outdoor/industrial environments confirmed by accelerated aging per IEC 60216.

- Corrosion Shield: Passes >7500 hours salt-spray & chemical fume exposure (ISO 9227/ASTM B117).

- Easy Handling: Non-tacky until applied, ensures zero tape "creep".

- Accreditation: Certified to ISO 9001, RoHS & REACH.

Typical dimensions: 19/25/38/50mm width × 0.76mm thick × 10m length, with custom cuts available.

Product Comparison Table: J30 vs. Major International Brands

| Property | J30 High-voltage EPR Tape | 3M Scotch® 130C | HELLERMANNTYTON HelaTape Power 810 |

|---|---|---|---|

| Dielectric Strength (kV/mm) | 44.0 | 42.8 | 41.5 |

| Thickness (mm) | 0.76 | 0.76 | 0.75 |

| Elongation at Break (%) | 960 | 900 | 850 |

| Operating Temp Range (°C) | -40 to +100 | -40 to +90 | -30 to +90 |

| Resistance to Water | Excellent | Excellent | Good |

| Accelerated Aging(Hrs) | > 7800 | 6500 | 5300 |

| Conformability | High | High | Medium |

Customized Solutions, Lead Time & Support

- Customization: J30 Tape can be supplied in custom widths (10mm-70mm), lengths, or pre-cut strips for your application.

- Delivery: Standard sizes ship within 72 hours ex-stock; custom orders in 7-15 days based on volume.

- Warranty: 3-year unconditional manufacturer warranty with 100% replacement for non-human faults.

- Support: Free technical consulting, on-site condition evaluation, and third-party testing reports available.

- Certifications: ISO9001, ISO14001, RoHS, SGS.

- After-sales: 24/7 hotline, rapid response for global partners.

Client Feedback, Industry Recognitions & Partners

J30 EPR Tape is trusted by leading power utilities, oil & gas majors, and engineering contractors worldwide.

- PowerChina, Sinopec, ABB—multiple 100,000+m power and chemical cable projects use J30 for long-life insulation.

- Independent lab tests (SGS 2023) confirmed “thermal life >23 yrs at 90°C”, exceeding even premium international benchmarks.

Professional Q&A: EPR Self Amalgamating Tape

1. MarketsandMarkets: Global Self-Amalgamating Tape Market Report 2023

2. IEEE Xplore: Performance of EPR Insulated Cable in Utility Service

3. ASTM D4388—Standard Specification for Rubber Tapes

4. POWER Engineering Intl: Field Experience—EPR vs. XLPE Cables

5. All About Circuits Forum: EPR vs XLPE Cable Selection Discussion

-

Types of Electrical and Industrial Tape and Their DifferencesNewsAug.04,2025

-

The Versatile Uses of Rubber Tape in Daily LifeNewsAug.04,2025

-

Key Features of Automotive Wire Harness PVC TapeNewsAug.04,2025

-

Key Benefits of Using Linerless Insulating Rubber Tape in Electrical WorkNewsAug.04,2025

-

How to Choose the Right Rubber TapeNewsAug.04,2025

-

How to Apply PVC Warning and Floor Marking Tape for Maximum DurabilityNewsAug.04,2025