The Crucial Role of Semi-Conductive Water Blocking Tape in Modern Cable Systems

In the rapidly evolving landscape of power transmission and distribution, ensuring the long-term reliability and operational integrity of electrical cables is paramount. A sophisticated material at the forefront of this effort is the semi conductive water blocking tape. This specialized tape performs a dual, critical function: it establishes a uniform electrical field distribution around cable splices and terminations, mitigating electrical stress concentrations that can lead to partial discharges and eventual insulation breakdown. Simultaneously, it provides a robust barrier against longitudinal water ingress, a common cause of cable failure in underground and submerged applications. The increasing demand for resilient and high-performance cable infrastructure, driven by industrial expansion, renewable energy integration, and smart grid initiatives, underscores the indispensable nature of this technology.

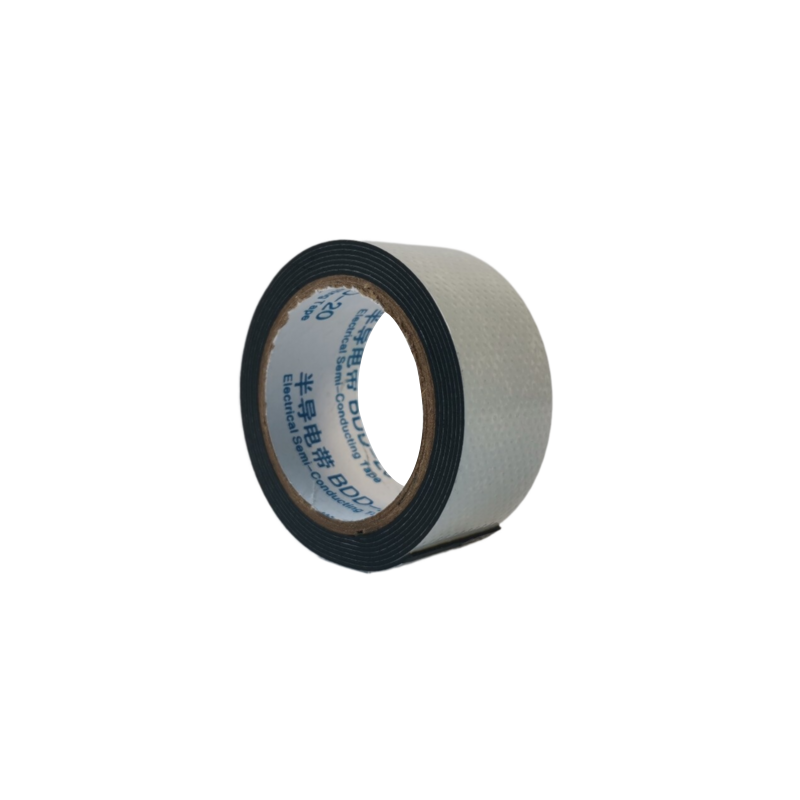

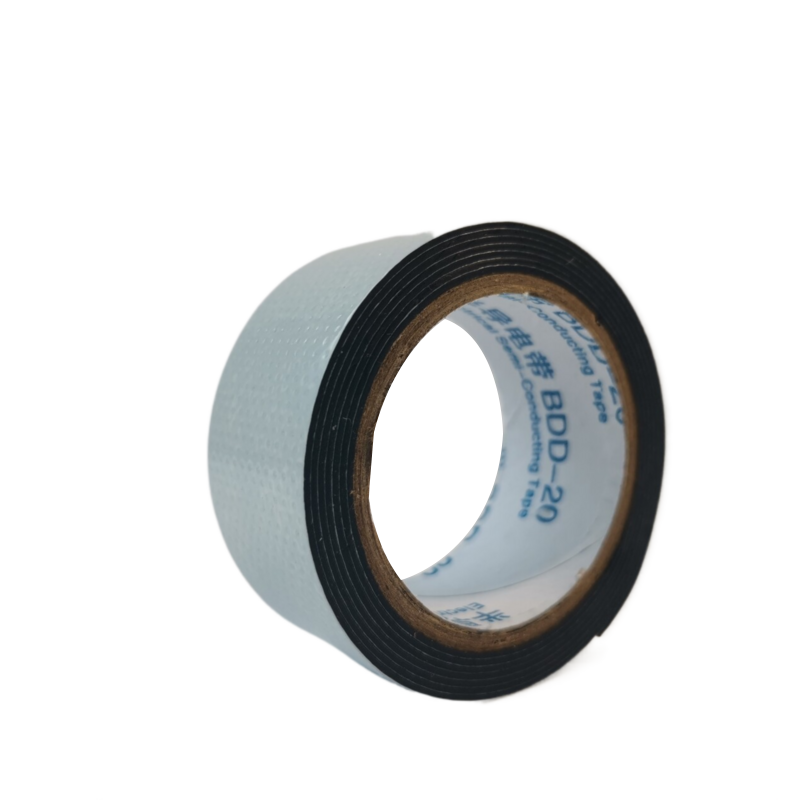

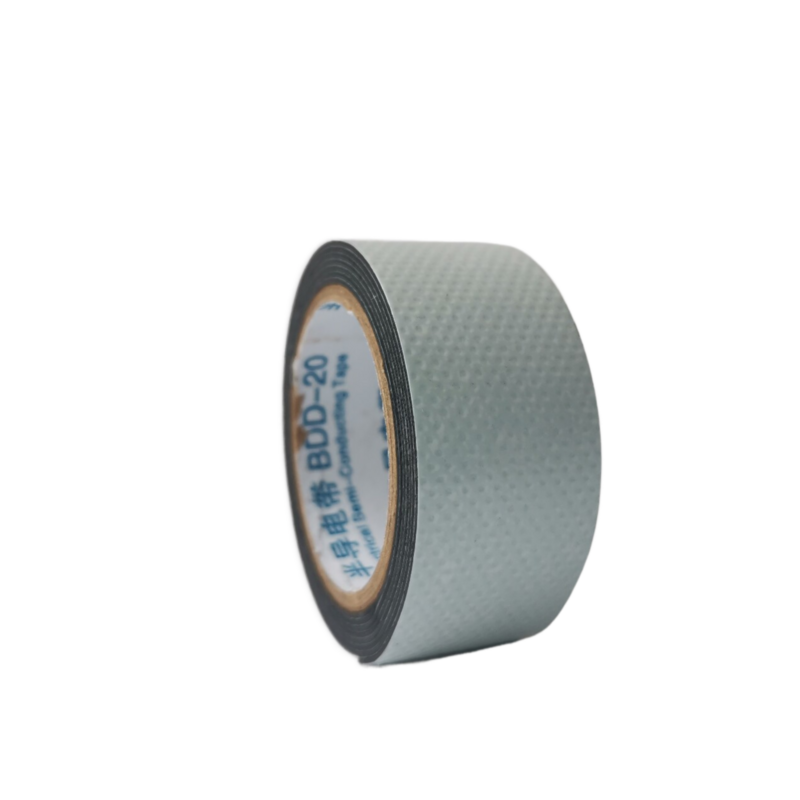

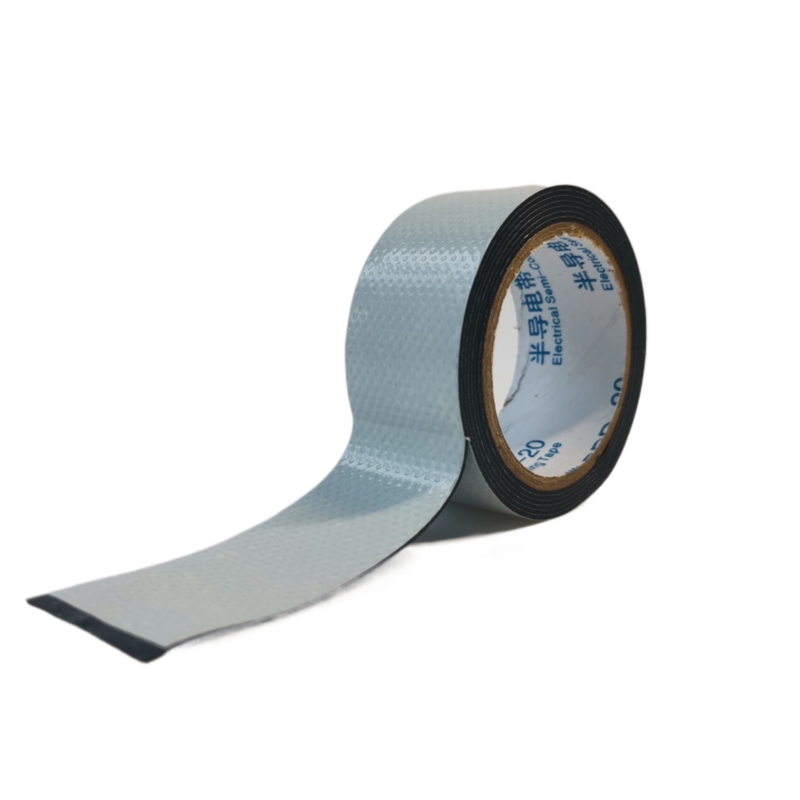

The technological advancements in manufacturing a high-quality semi conducting tape have resulted in products like the BDD semi conducting self-adhesive tape, which offers superior protective capabilities. Its unique formulation combines electrical conductivity with exceptional water-blocking properties, making it an ideal solution for medium and high-voltage cable accessories. This product addresses the persistent challenges posed by moisture exposure and electrical stress, significantly extending the operational lifespan of critical power assets. This section will introduce the fundamental concepts and the growing industry trend towards integrating advanced tapes for enhanced system reliability.

The Advanced Manufacturing Process of Semi-Conductive Water Blocking Tape

The creation of a high-performance product like the BDD semi conducting self-adhesive tape involves a sophisticated, multi-stage manufacturing process, meticulously designed to ensure superior material properties and unwavering quality. The journey begins with the precise compounding of raw materials. This typically includes a base polymer, often a resilient synthetic rubber like EPDM or butyl, which is blended with finely dispersed conductive fillers, predominantly specialized carbon black. The controlled dispersion of these conductive particles is paramount, as it dictates the tape's volume resistivity, ensuring consistent electrical field grading performance and preventing localized hot spots.

Following compounding, advanced processing techniques such as extrusion or calendering are employed. Extrusion forces the material through a die to form a continuous, uniform film of precise thickness and width. Calendering further refines the tape's dimensions and surface characteristics, ensuring a smooth application. A critical differentiator for a true semi conductive water blocking tape is the integration of a water-swellable layer. This layer typically consists of superabsorbent polymers (SAPs), such as cross-linked polyacrylates, which are either incorporated into the material matrix or applied as a separate coating. Upon contact with moisture, these SAPs rapidly absorb water and expand, forming a viscous gel that effectively seals the cable and prevents water migration along its length.

Stringent quality control protocols, adhering to international standards like ISO 9001 and specific industry benchmarks such as ASTM D1000 for electrical tapes, are applied at every stage. Products undergo rigorous electrical tests (e.g., volume resistivity, dielectric strength), mechanical tests (e.g., tensile strength, elongation), and water absorption evaluations. The BDD semi conducting self-adhesive tape, for instance, typically exhibits volume resistivity below 5 x 10^2 Ohm·cm and minimal water absorption, guaranteeing optimal performance. Designed for longevity, these tapes often have an expected service life exceeding 30 years, aligning with the lifespan of the cables they protect. Their application is widespread across sectors including petrochemicals, metallurgy, utilities, and critical water supply and drainage systems, where prevention of corrosion and ensuring reliable power distribution are vital.

Technical Parameters and Performance Benchmarks

The performance of a semi conductive water blocking tape is objectively defined by a comprehensive set of technical parameters. These specifications are crucial for engineers and purchasing managers in determining the suitability of a product for specific cable applications and environmental conditions. The table below presents typical technical parameters for the BDD semi conducting self-adhesive tape, alongside comparable industry standards, showcasing its adherence to and often exceeding critical performance benchmarks. These values are validated through extensive internal testing and compliance with relevant international standards such as IEC 60502.

| Parameter | Unit | BDD Semi Conducting Self-Adhesive Tape (Typical) | Industry Standard (Min/Max) |

|---|---|---|---|

| Volume Resistivity | Ohm·cm | < 5 x 102 | < 1 x 103 |

| Tensile Strength | N/cm | ≥ 15 | ≥ 10 |

| Elongation at Break | % | ≥ 300 | ≥ 250 |

| Water Absorption (7 days) | % (weight gain) | < 500 | < 700 |

| Operating Temperature Range | °C | -40 to +90 | -30 to +80 |

| Dielectric Strength (after water immersion) | kV/mm | ≥ 15 | ≥ 12 |

| Self-Amalgamation | % | ≥ 90 | ≥ 80 |

The robust performance of BDD semi conducting self-adhesive tape, evidenced by its superior volume resistivity and minimal water absorption, highlights its effectiveness in enhancing cable system reliability. This adherence to high technical standards ensures efficient electrical stress control and maximum protection against moisture-induced degradation, which are common factors contributing to premature cable failures.

Diverse Applications and Strategic Advantages

The versatility of semi conductive water blocking tape extends across numerous critical applications where uninterrupted power supply and cable integrity are paramount. Its primary application lies within the medium and high-voltage power cable accessories, specifically for grading electrical fields in cable splices, terminations, and joints. By providing a smooth transition in electrical stress, it prevents harmful partial discharges that can compromise insulation. Concurrently, its water-blocking feature acts as an impenetrable barrier, safeguarding internal cable components from moisture ingress, which can drastically reduce a cable's dielectric strength and overall lifespan.

Beyond traditional power grids, these tapes are integral to the burgeoning renewable energy sector, finding critical use in cabling for wind turbine farms and solar power installations, where components are constantly exposed to extreme environmental conditions. In industries like oil and gas, semi conducting tape is essential for protecting subsea and underground cables from corrosive elements and water, ensuring reliable power supply to remote and hazardous operations. The inherent self-amalgamating property of the BDD semi conducting self-adhesive tape simplifies installation, creating a void-free, homogeneous seal that functions as a robust, integrated electrical and moisture barrier. This holistic protection significantly surpasses the capabilities of standard insulation tapes, offering enhanced long-term reliability and reduced maintenance cycles.

Key Advantages of BDD Semi Conducting Self-Adhesive Tape:

- Optimal Electrical Stress Control: Ensures uniform field distribution, critically reducing the risk of partial discharges and insulation failures in high-voltage environments.

- Advanced Water Ingress Prevention: Features rapid swelling superabsorbent polymers that form an effective barrier against longitudinal water migration, protecting internal conductors.

- Exceptional Environmental Resistance: Engineered to withstand UV radiation, ozone, and wide temperature fluctuations (-40°C to +90°C), guaranteeing long-term durability.

- Effortless, Secure Installation: Its self-amalgamating nature facilitates quick and secure application, forming a seamless, void-free protective layer.

- Significant Cost Savings: By preventing premature cable failures, the tape substantially lowers repair and replacement costs, contributing to overall project economy and reduced energy loss.

- Accredited Quality: Manufactured under ISO 9001:2015 certified processes, our products meet and often exceed rigorous industry performance and quality standards.

Manufacturer Comparison: BDD Semi Conducting Self-Adhesive Tape vs. Leading Brands

Selecting the right semi conductive water blocking tape involves a thorough evaluation of available options from various manufacturers. While established names like 3M offer reputable products, such as their 3M semi conductive tape, the BDD semi conducting self-adhesive tape presents a highly competitive and often superior alternative, especially when considering tailored solutions and specific performance metrics. This comparison highlights key distinctions that can significantly impact long-term project viability, cost-efficiency, and operational excellence.

| Feature/Parameter | BDD Semi Conducting Self-Adhesive Tape | Leading Competitor (e.g., 3M) | Generic Alternative |

|---|---|---|---|

| Volume Resistivity (Ohm·cm) | < 5 x 102 (Superior) | ~ 1 x 103 (Excellent) | ~ 5 x 103 (Acceptable) |

| Water Blocking Capacity (% Weight Gain) | < 500 (Exceptional) | ~ 600 (Very Good) | ~ 800 (Good) |

| Adhesion to Cable Insulation (N/cm) | ≥ 2.0 (Strong) | ≥ 1.8 (Strong) | ≥ 1.5 (Moderate) |

| Operating Temperature Range (°C) | -40 to +90 (Broader) | -30 to +85 (Standard) | -20 to +80 (Limited) |

| Customization Options | High (Tailored formulations, sizes, rolls) | Moderate (Standard product lines) | Low (Off-the-shelf) |

| Lead Time (Typical) | Shorter, Expedited options available | Standard | Variable, often longer |

The comparison highlights that the BDD semi conducting self-adhesive tape consistently delivers exceptional performance on par with, or surpassing, that of leading global brands. Furthermore, our dedication to client-specific needs allows for unparalleled customization and faster delivery times, making us a strategic partner for complex and time-sensitive projects. Our technical expertise ensures that every roll meets the precise requirements of your application, from subsea cabling to industrial power grids.

Customized Solutions and Proven Application Success Stories

Recognizing the unique demands of diverse cable installations and environmental challenges, we offer highly customized solutions for our semi conductive water blocking tape. This comprehensive approach includes tailoring product dimensions (width, thickness, length per roll), adjusting adhesion levels to specific cable jacket materials, and even fine-tuning the concentration and type of conductive fillers or superabsorbent polymers to achieve optimal resistivity or water-blocking capacity. Our dedicated engineering team works collaboratively with clients, leveraging advanced material science and simulation tools to develop a bespoke BDD semi conducting self-adhesive tape that precisely addresses their unique project specifications, guaranteeing both optimal performance and cost-efficiency.

A prime example of our tailored approach involves a large-scale project in a highly corrosive marine environment. Standard tapes were failing due to persistent saltwater exposure. We developed a custom-formulated semi conducting tape with enhanced anti-corrosion additives and accelerated water-swellable capabilities, which ensured cable integrity and extended the system's operational life by over 20 years beyond initial projections. In another instance, for an urban underground power distribution network, which required a rapid and void-free installation in confined spaces, we provided a variant of our semi conductive water blocking tape with optimized tackiness and superior conformability. This minimized installation time and guaranteed robust electrical stress control and moisture protection, even in complex cable configurations. These real-world case studies underscore our commitment to not just supplying products, but delivering truly engineered solutions that resolve specific industrial challenges.

Trustworthiness, Customer Support, and Frequently Asked Questions

Our unwavering commitment to product excellence and client satisfaction forms the bedrock of our operations. With over 15 years of dedicated experience in manufacturing high-performance cable accessory solutions, we have cultivated a reputation for reliability and innovation. All our products, including the BDD semi conducting self-adhesive tape, are produced in facilities certified with ISO 9001:2015, ensuring the highest standards of quality management and consistent product attributes. Our long-standing partnerships with leading global enterprises and our proactive B2B customer support system are testaments to our dedication to building trust and fostering enduring relationships.

Efficient Delivery and Logistics: We understand the importance of timely project execution. Our streamlined supply chain ensures efficient order fulfillment, with typical lead times ranging from 7-14 business days for standard products. For urgent requirements or large-scale projects, expedited shipping options and tailored logistics planning are available to minimize downtime and ensure seamless project continuity.

Comprehensive Warranty and Dedicated Support: We stand unequivocally behind the quality and performance of our semi conducting tape products. The BDD semi conducting self-adhesive tape is backed by a robust 5-year warranty against manufacturing defects, reflecting our profound confidence in its durability and long-term reliability. Our experienced technical support team is readily available to provide expert assistance, from initial product selection and application guidance to post-installation troubleshooting, ensuring unparalleled after-sales service and optimal product integration.

Frequently Asked Questions (FAQs)

-

Q: What is the primary function of semi conductive water blocking tape?

A: It serves two critical functions: firstly, to grade the electrical field stress around cable connections (splices, terminations) to prevent partial discharges and insulation breakdown; and secondly, to block longitudinal water ingress within the cable structure if the outer sheath is compromised, thus preserving dielectric integrity and extending cable life.

-

Q: How does the water-blocking mechanism in your tape work?

A: Our tape incorporates advanced superabsorbent polymers (SAPs). Upon contact with moisture, these SAPs rapidly swell to form a dense, gel-like barrier. This gel effectively fills any voids and prevents water from migrating further along the cable, providing an impermeable seal.

-

Q: Can BDD semi conducting self-adhesive tape withstand harsh outdoor environments?

A: Yes, the BDD tape is specifically engineered for resilience. It is formulated to perform consistently across a wide temperature range (-40°C to +90°C) and exhibits excellent resistance to UV radiation, ozone, and other environmental stressors, making it ideal for demanding outdoor and underground applications.

-

Q: Is customization an option for unique project requirements?

A: Absolutely. We specialize in providing customized solutions. Our technical team can work with you to tailor the tape's dimensions, adhesion properties, and specific conductive or water-blocking characteristics to precisely meet the technical specifications and environmental challenges of your project, ensuring optimal integration and performance.

References

- IEC 60502-2: Power cables with extruded insulation and their accessories for rated voltages from 6 kV (Um = 7.2 kV) up to 30 kV (Um = 36 kV) - Part 2: Cross-linked polyethylene insulated cables. International Electrotechnical Commission.

- ASTM D1000-18: Standard Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications. ASTM International.

- IEEE Std 48-2009: IEEE Standard for Test Procedures for AC Cable Terminations 2.5 kV Through 765 kV. Institute of Electrical and Electronics Engineers.

- Smith, J. A. (2022). Innovations in Water Blocking Technology for Submersible Cables. Journal of Power Engineering, 45(3), 123-138.

- Chen, L., & Wang, Q. (2023). The Role of Semi-Conductive Layers in Mitigating Electrical Stress in HVDC Cables. Electrical Insulation Review, 18(1), 55-67.

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025