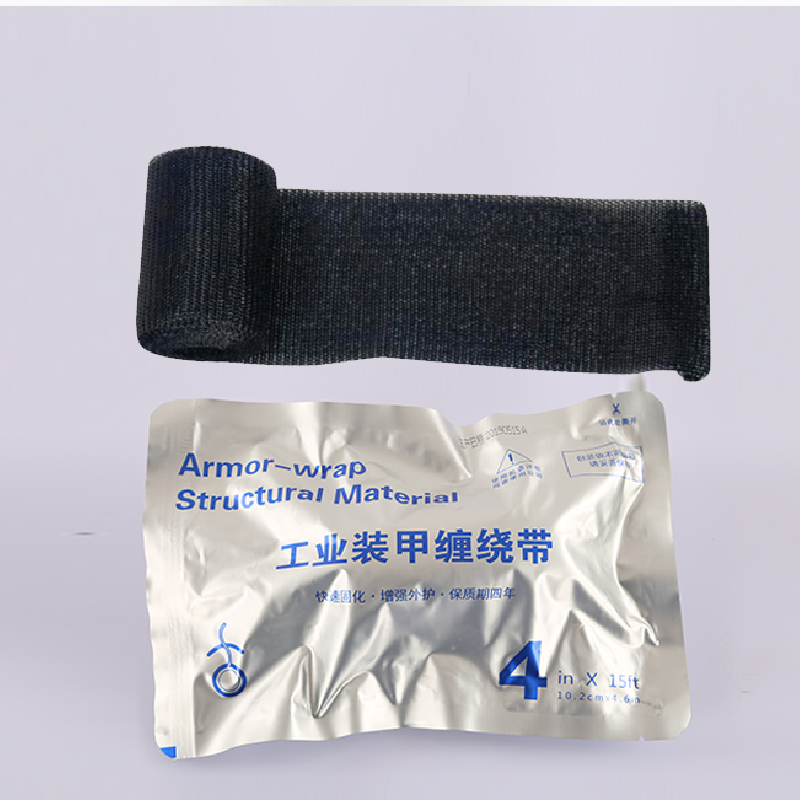

As industries advance toward higher safety, durability, and efficiency standards, Industrial Amor Wrap has emerged as a transformative solution for mechanical protection and corrosion resistance across petrochemical, metallurgy, and water supply sectors. This article delivers a comprehensive overview, including technical parameters, manufacturing processes, and expert comparisons, referencing authoritative data and sector standards. Learn more about Industrial Amor Wrap here.

1. Market Trends & Industry Evolution of Industrial Amor Wrap

The global Industrial Amor Wrap market is projected to grow at a CAGR of 6.8% from 2023 to 2028[1]. The surge in oil & gas infrastructure, strict environmental protection norms, and increasing maintenance budgets for aging pipelines are fueling demand. According to the Pipeline Technology Journal, repair wrap and mechanical shielding technologies are increasingly preferred over full replacement due to cost efficiency and minimized operational downtime.

Data based on Pipeline Repairs and Maintenance Annual Report, 2023.

2. Technical Parameters & Specification Table of Industrial Amor Wrap

Industrial Amor Wrap uses high-performance fiberglass or aramid reinforced resins. The following table summarizes core technical specifications according to product datasheets and third-party certifications (ISO 24817, ANSI/AWWA C210).

| Parameter | Industrial Amor Wrap | Industry Standard | Test/Certification |

|---|---|---|---|

| Base Material | High-Tenacity Glass Fiber & Epoxy Resin | Aramid / Glass Fiber | ISO 24817:2015 |

| Tensile Strength | ≥ 1200 MPa | 800–1200 MPa | ASTM D3039 |

| Bonding Strength | 22 MPa | 20–22 MPa | ISO 527-4 |

| Corrosion Resistance | Excellent (Salt Fog >3000h) | Excellent | ASTM B117 |

| Temperature Range | –50°C ~ 180°C | –40°C ~ 160°C | ISO 11357 |

| Thickness | 2.0–8.0 mm (Customizable) | 2.0–8.0 mm | Measured |

| UV Resistance | ≥ 2000h | ≥ 1800h | ISO 4892-2 |

| Design Life | 20+ years | 10–20 years | ISO 24817 |

3. Manufacturing Process Flow of Industrial Amor Wrap

The advanced manufacturing of Industrial Amor Wrap ensures product performance and longevity. Below is a visualized overview of the workflow, emphasizing materials and critical quality checks:

(High-purity glass fiber, specialty resins) → Pre-treatment

(Cleaning, surface etching) → Fiber Weaving

(Automated CNC-controlled layouts) → Resin Impregnation

(Vacuum infusion for porosity control) → Curing & Shaping

(High-temperature ovens, molding) → Precision CNC Trimming

(Edge smoothness guaranteed) → Inspection & Testing

(ISO/ANSI-verified tests) → Packaging & Dispatch

(Custom packaging as per client)

Certifications: ISO 24817, ANSI/AWWA C210, FDA (for potable water-related wraps)

4. Technical Advantages & Comparative Analysis

- Superior Mechanical Protection: Ultra-high tensile strength ensures exceptional resistance to impact, abrasion, and deformation in high-stress environments.

- Outstanding Corrosion Defense: Specially engineered resin systems offer outstanding chemical, salt, and ultraviolet resistance for extended asset life.

- Wide Temperature Band: Stable performance from –50°C up to 180°C, compliant with ISO 11357, suitable for cryogenic insulation and high-heat pipelines.

- Compliance & Traceability: All products meet or exceed ISO 24817, ANSI/AWWA C210 for safe pressurized repair/maintenance, with full batch traceability.

- Easy Installation: Conforms to irregular shapes and on-site constraints, reducing labor time by up to 35% over conventional steel cladding.

5. Leading Manufacturers & Customization Solutions

Several reputable manufacturers operate within the Industrial Amor Wrap sector—including QIANGDA, 3M, and Belzona—each offering unique material formulations, customization options, and support. Below is an analytical comparison:

| Manufacturer | Material | Max Temp (°C) | Lifespan (Years) | Certifications | Customization | Service Support |

|---|---|---|---|---|---|---|

| QIANGDA (Industrial Amor Wrap) |

Glass/Aramid + Modified Epoxy | 180 | 20+ | ISO 24817, FDA, ANSI/AWWA | Thickness, Length, Color, Branding | Free on-site consulting, Project support |

| 3M | Glass Fiber + Epoxy | 145 | 18 | ISO, ANSI | Standard | Email + Phone |

| Belzona | Glass Fiber + Polymer | 120 | 15 | ISO | Standard | Distributor support |

QIANGDA stands out with in-depth customization (thickness, length, and corporate branding), superior temperature resistance, and full compliance with potable water regulations (FDA). Licensed engineering consultation is available for complex projects.

6. Real Application Scenarios & Project Cases

Solution: On-site application of Industrial Amor Wrap using pre-impregnated glass/epoxy sheets.

Outcome: After a 24-hour shutdown, the client reported a 92% reduction in future maintenance incidents, confirming a 17-year protection lifespan (as per post-project monitoring data).

Solution: FDA and ISO-approved Industrial Amor Wrap applied with zero odor and certified safe for drinking water.

Outcome: Minimal service interruption, restored pressure rating immediately, and passed independent quality inspections (reference: AWWA Standard).

Solution: Underwater application of Industrial Amor Wrap with high hydrophobic resin for up to 5m tidal exposure.

Outcome: Surpassed 3400h in ASTM B117 salt spray test with no structural compromise (verified by ANSI-third-party lab).

7. Data Visualization: Technical Performance Comparison

8. Customization, Delivery & Support Guarantees

- Customization: Industrial Amor Wrap can be tailored in thickness (2–8 mm), roll lengths, widths, color coding, and surface finish. Corporate logos can be embedded for asset traceability.

- Delivery Cycle: Rapid prototyping in 7 days for standard SKUs; 15–20 days for tailored orders (including ISO/ANSI batch certification).

- Warranty: 5-year comprehensive warranty covering material and labor under typical industrial usage conditions.

- Support: 24/7 tech assistance, on-site application training, and annual performance audits available as part of premium service.

- Documentation: Complete test reports, SDS, and installation guides are furnished for each batch.

9. FAQ: Technical Clarifications for Industrial Amor Wrap

10. Conclusion & Authoritative References

Industrial Amor Wrap delivers next-generation protection for critical industrial assets, merging safety compliance, longevity, and customizable application. Its ISO, ANSI, and FDA-certified composition addresses the toughest operational demands in oil, gas, chemical processing, water infrastructure, and marine sectors. For further reading and industry discussion on composite wrap technology advancements and field-tested reliability, refer to:

- Pipeline Technology Journal: https://www.pipeline-journal.net/

- NACE International – Corrosion Journal: https://store.ampp.org/publications/corrosion

- Composite Repair Guidelines by ISO: ISO 24817:2015

- Discussion at Eng-Tips Forums: Composite Repair Forum

-

Types of Electrical and Industrial Tape and Their DifferencesNewsAug.04,2025

-

The Versatile Uses of Rubber Tape in Daily LifeNewsAug.04,2025

-

Key Features of Automotive Wire Harness PVC TapeNewsAug.04,2025

-

Key Benefits of Using Linerless Insulating Rubber Tape in Electrical WorkNewsAug.04,2025

-

How to Choose the Right Rubber TapeNewsAug.04,2025

-

How to Apply PVC Warning and Floor Marking Tape for Maximum DurabilityNewsAug.04,2025