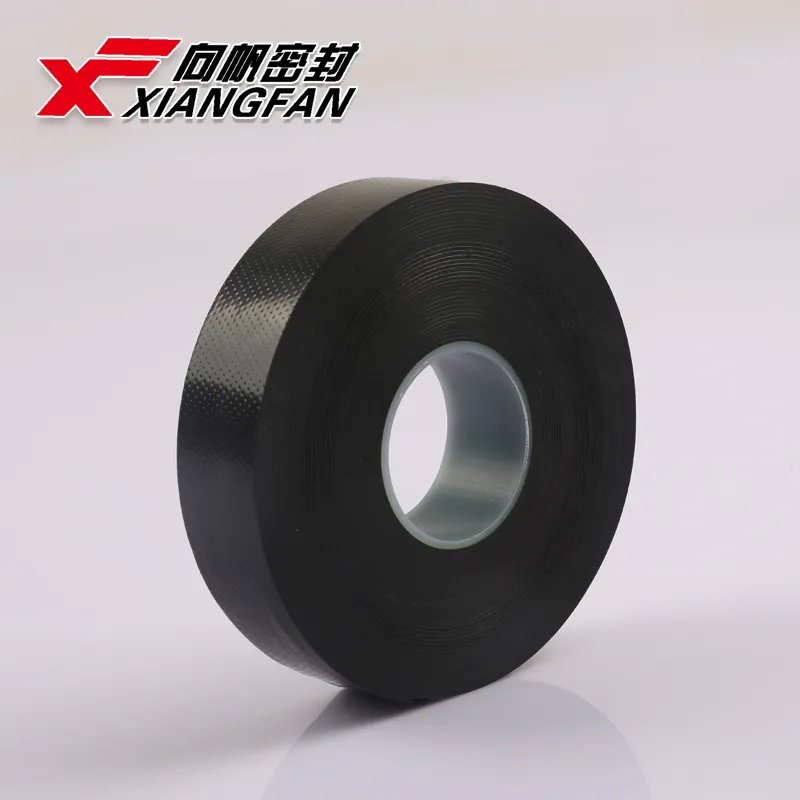

Butyl Rubber Tape

Back to list

កុម្ភៈ . 15, 2025 17:18

Butyl rubber roll insulation is an innovative and versatile material offering unparalleled solutions for a multitude of industrial and commercial applications. Known for its high impermeability to gas and moisture, it stands as the go-to choice for industries requiring reliable sealing capabilities.

Authoritative sources emphasize the significance of using butyl rubber roll for window sealants in building constructions. Its high-performance insulation properties significantly reduce energy costs, contributing to more sustainable building practices. Incorporating butyl rubber roll in constructions not only supports energy-efficient standards but also offers superior sealing during glass installation, ensuring long-term serviceability of windows and facades. Trust in butyl rubber roll is consistently reinforced by its proven track record and widespread use in NASA space suits and medical applications. Its hypoallergenic attributes along with impeccable airtight properties underscore its reliability even in critical environments where failure is not an option. When sourcing butyl rubber rolls, it is paramount to select high-quality materials from reputable manufacturers. Investing in butyl rubber with enhanced properties ensures optimal performance and returns in the long run. Moreover, utilizing professionally trained personnel for installation maximizes the benefits and reduces potential issues resulting from improper application. Intricately understanding product specifications and performance standards when choosing butyl rubber roll is crucial to application success. Stay informed about innovative advancements within the field, such as butyl rubber containing advanced fillers that improve durability and environmental resistance. These improvements not only bolster the material's capabilities but also align with progressive industry standards for sustainability and efficiency. In conclusion, butyl rubber roll stands out as an exemplary material for those seeking durable, reliable, and efficient sealing solutions. Its proven and consistent performance across various applications makes it a benchmark for industries aiming to enhance their product performance and material longevity. Keeping abreast of industry advancements and applying expert-recommended practices ensures optimization of butyl rubber roll benefits, solidifying its position as an industrial staple.

Authoritative sources emphasize the significance of using butyl rubber roll for window sealants in building constructions. Its high-performance insulation properties significantly reduce energy costs, contributing to more sustainable building practices. Incorporating butyl rubber roll in constructions not only supports energy-efficient standards but also offers superior sealing during glass installation, ensuring long-term serviceability of windows and facades. Trust in butyl rubber roll is consistently reinforced by its proven track record and widespread use in NASA space suits and medical applications. Its hypoallergenic attributes along with impeccable airtight properties underscore its reliability even in critical environments where failure is not an option. When sourcing butyl rubber rolls, it is paramount to select high-quality materials from reputable manufacturers. Investing in butyl rubber with enhanced properties ensures optimal performance and returns in the long run. Moreover, utilizing professionally trained personnel for installation maximizes the benefits and reduces potential issues resulting from improper application. Intricately understanding product specifications and performance standards when choosing butyl rubber roll is crucial to application success. Stay informed about innovative advancements within the field, such as butyl rubber containing advanced fillers that improve durability and environmental resistance. These improvements not only bolster the material's capabilities but also align with progressive industry standards for sustainability and efficiency. In conclusion, butyl rubber roll stands out as an exemplary material for those seeking durable, reliable, and efficient sealing solutions. Its proven and consistent performance across various applications makes it a benchmark for industries aiming to enhance their product performance and material longevity. Keeping abreast of industry advancements and applying expert-recommended practices ensures optimization of butyl rubber roll benefits, solidifying its position as an industrial staple.

Next:

Latest news

-

Types of Electrical and Industrial Tape and Their DifferencesNewsAug.04,2025

-

The Versatile Uses of Rubber Tape in Daily LifeNewsAug.04,2025

-

Key Features of Automotive Wire Harness PVC TapeNewsAug.04,2025

-

Key Benefits of Using Linerless Insulating Rubber Tape in Electrical WorkNewsAug.04,2025

-

How to Choose the Right Rubber TapeNewsAug.04,2025

-

How to Apply PVC Warning and Floor Marking Tape for Maximum DurabilityNewsAug.04,2025