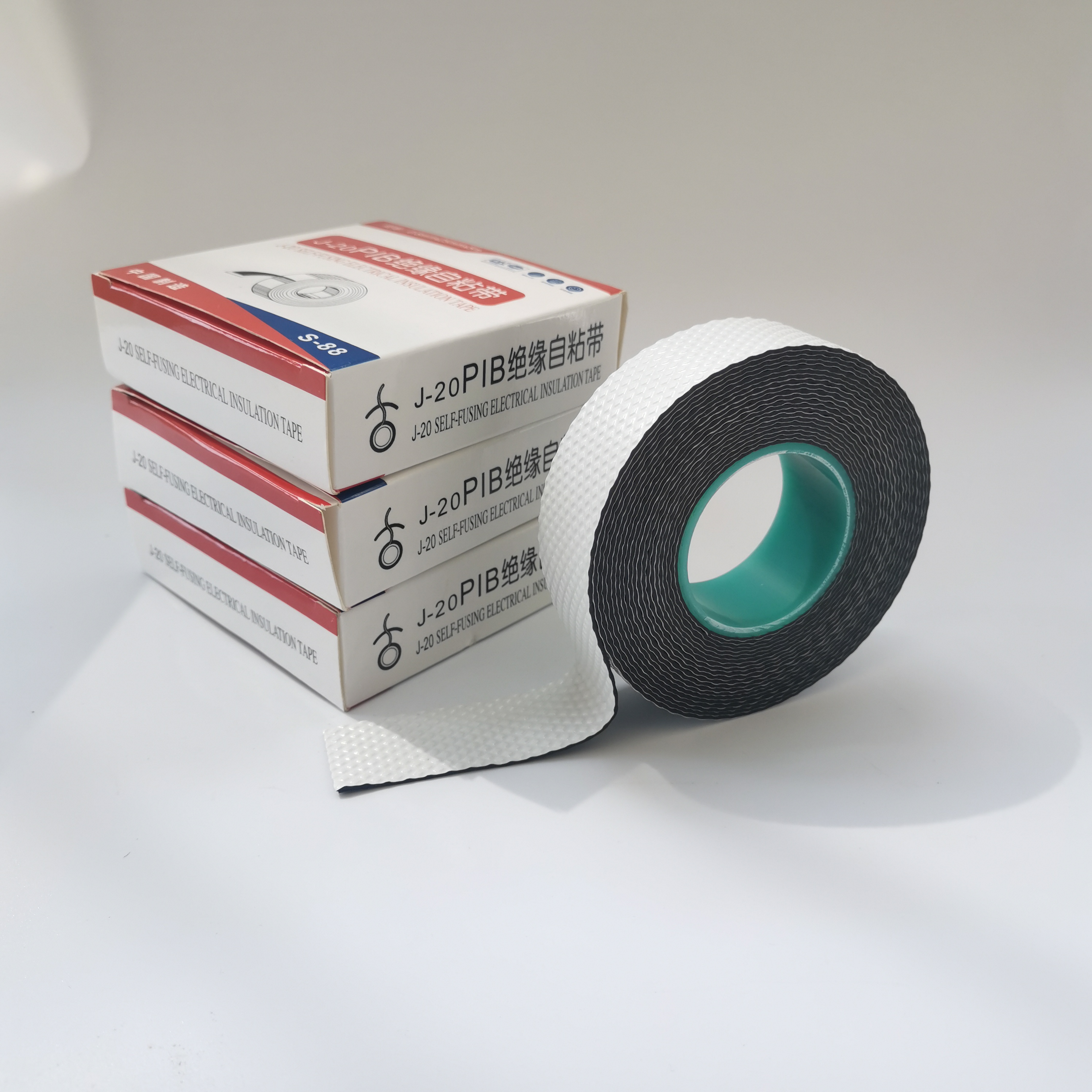

flame retardant insulation tape

Back to list

មករា . 17, 2025 00:46

Flame retardant insulation tape, often an unsung hero in industrial and residential applications, stands as a crucial component in ensuring the safety and reliability of electrical systems. For decades, this specialized tape has shielded electrical components from potential hazards, offering a reliable solution where both insulation and fire resistance are paramount.

Furthermore, expertise in selecting the right tape extends beyond just ensuring compatibility with the electrical specifications. Environmental considerations, such as exposure to UV light, humidity, and potential chemical exposure, should guide one's choice. A professional involved in the marine industry, where equipment is routinely exposed to saltwater and fluctuating temperatures, explained that using a substandard product could quickly lead to corrosion and failure of crucial components. The right flame retardant tape not only provides insulation but also resists these harsh conditions, demonstrating its multi-functional benefits. Building trustworthiness in flame retardant insulation tape depends largely on honesty regarding its capabilities and boundaries. While it serves as an effective temporary solution in critical repairs, it is not a substitute for comprehensive safety measures and should not encourage complacency in regular maintenance schedules. Transparency from manufacturers about these limitations further builds confidence and establishes long-term relationships with consumers. Incorporating flame retardant insulation tape into your toolkit means investing in peace of mind and operational efficiency. It plays a vital role in preventative maintenance strategies, adding an additional layer of security and assurance that fires or electrical failures won't propagate from a single point of failure. As innovations continue, integrating cutting-edge material technologies, the efficacy and application scope of flame retardant insulation tapes will likely expand, further cementing their position as an essential component in advanced electrical and safety engineering domains. Ultimately, understanding and harnessing the capabilities of flame retardant insulation tape involves a commitment to quality and safety. In the high-stakes environment of electrical installations, it is this commitment that turns tape into a tool of assurance, shielding both assets and lives against unforeseen and potentially catastrophic events.

Furthermore, expertise in selecting the right tape extends beyond just ensuring compatibility with the electrical specifications. Environmental considerations, such as exposure to UV light, humidity, and potential chemical exposure, should guide one's choice. A professional involved in the marine industry, where equipment is routinely exposed to saltwater and fluctuating temperatures, explained that using a substandard product could quickly lead to corrosion and failure of crucial components. The right flame retardant tape not only provides insulation but also resists these harsh conditions, demonstrating its multi-functional benefits. Building trustworthiness in flame retardant insulation tape depends largely on honesty regarding its capabilities and boundaries. While it serves as an effective temporary solution in critical repairs, it is not a substitute for comprehensive safety measures and should not encourage complacency in regular maintenance schedules. Transparency from manufacturers about these limitations further builds confidence and establishes long-term relationships with consumers. Incorporating flame retardant insulation tape into your toolkit means investing in peace of mind and operational efficiency. It plays a vital role in preventative maintenance strategies, adding an additional layer of security and assurance that fires or electrical failures won't propagate from a single point of failure. As innovations continue, integrating cutting-edge material technologies, the efficacy and application scope of flame retardant insulation tapes will likely expand, further cementing their position as an essential component in advanced electrical and safety engineering domains. Ultimately, understanding and harnessing the capabilities of flame retardant insulation tape involves a commitment to quality and safety. In the high-stakes environment of electrical installations, it is this commitment that turns tape into a tool of assurance, shielding both assets and lives against unforeseen and potentially catastrophic events.

Latest news

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025