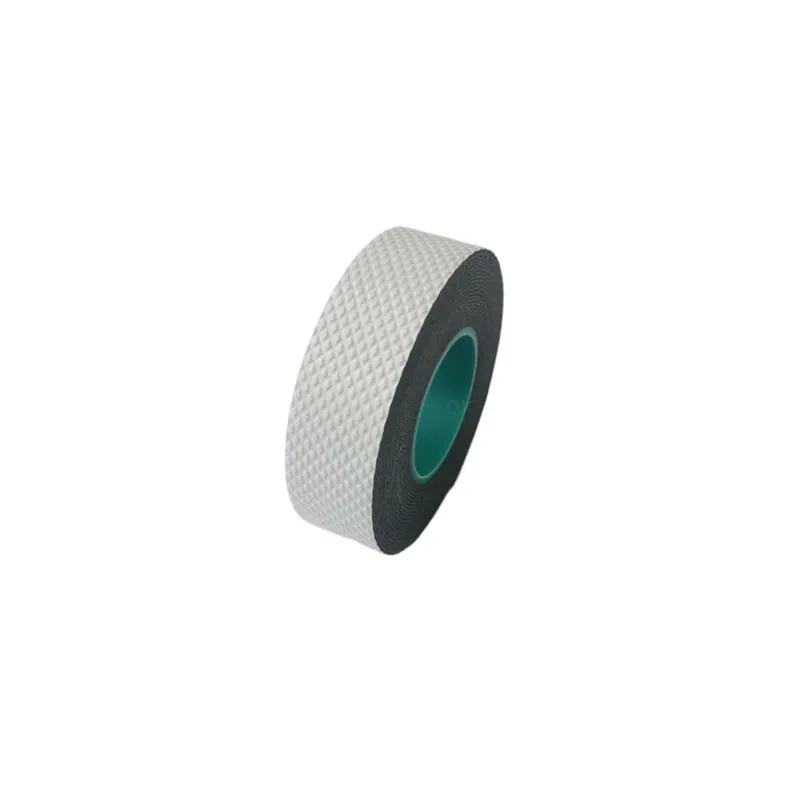

high speed splicing tape

Back to list

កុម្ភៈ . 11, 2025 21:13

High speed splicing tape has revolutionized various industries by offering unprecedented efficiency in production lines. As an industry expert with extensive experience, I have witnessed firsthand the transformative impact of this innovative product, particularly in fields such as packaging, printing, and paper production. This specialized tape ensures that the transition between material rolls occurs seamlessly, significantly minimizing downtime and thereby amplifying productivity.

Trustworthiness is key when selecting high speed splicing tape. Users need assurance that the tape will hold up under the demands of high-speed machinery. Reputable manufacturers conduct rigorous testing to ensure their products consistently deliver the promised performance. Adherence to stringent quality standards not only guarantees reliability but also builds confidence among users, enhancing this product’s stature as a trusted solution in industrial applications. In addition to its functional benefits, cost-effectiveness is another compelling advantage. The efficiency gains achieved through the use of high speed splicing tape often lead to a quick return on investment. By reducing machine downtime and material wastage, companies can achieve greater output with less input. This economic efficiency, coupled with the product’s operational benefits, underscores its value in competitive industries where marginal enhancements can lead to significant gains. Innovative high speed splicing tapes are also making strides towards environmental sustainability. Modern variants are designed with eco-friendly adhesives and materials that reduce overall environmental impact, aligning with global efforts toward sustainable industrial practices. Companies adopting these tapes not only improve their operational efficiency but also contribute to broader environmental objectives, enhancing their brand reputation as a responsible business entity. In conclusion, high speed splicing tape is more than just an adhesive solution; it is a cornerstone of modern industrial efficiency. Its ability to enhance productivity, customization to meet specific requirements, and adherence to stringent quality standards make it an authoritative choice in any manufacturing setting. By combining expert adhesive technology with reliable performance, high speed splicing tape stands as a testament to innovation in industrial operations, providing companies with the tools they need to succeed in today’s fast-paced production environments.

Trustworthiness is key when selecting high speed splicing tape. Users need assurance that the tape will hold up under the demands of high-speed machinery. Reputable manufacturers conduct rigorous testing to ensure their products consistently deliver the promised performance. Adherence to stringent quality standards not only guarantees reliability but also builds confidence among users, enhancing this product’s stature as a trusted solution in industrial applications. In addition to its functional benefits, cost-effectiveness is another compelling advantage. The efficiency gains achieved through the use of high speed splicing tape often lead to a quick return on investment. By reducing machine downtime and material wastage, companies can achieve greater output with less input. This economic efficiency, coupled with the product’s operational benefits, underscores its value in competitive industries where marginal enhancements can lead to significant gains. Innovative high speed splicing tapes are also making strides towards environmental sustainability. Modern variants are designed with eco-friendly adhesives and materials that reduce overall environmental impact, aligning with global efforts toward sustainable industrial practices. Companies adopting these tapes not only improve their operational efficiency but also contribute to broader environmental objectives, enhancing their brand reputation as a responsible business entity. In conclusion, high speed splicing tape is more than just an adhesive solution; it is a cornerstone of modern industrial efficiency. Its ability to enhance productivity, customization to meet specific requirements, and adherence to stringent quality standards make it an authoritative choice in any manufacturing setting. By combining expert adhesive technology with reliable performance, high speed splicing tape stands as a testament to innovation in industrial operations, providing companies with the tools they need to succeed in today’s fast-paced production environments.

Latest news

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025